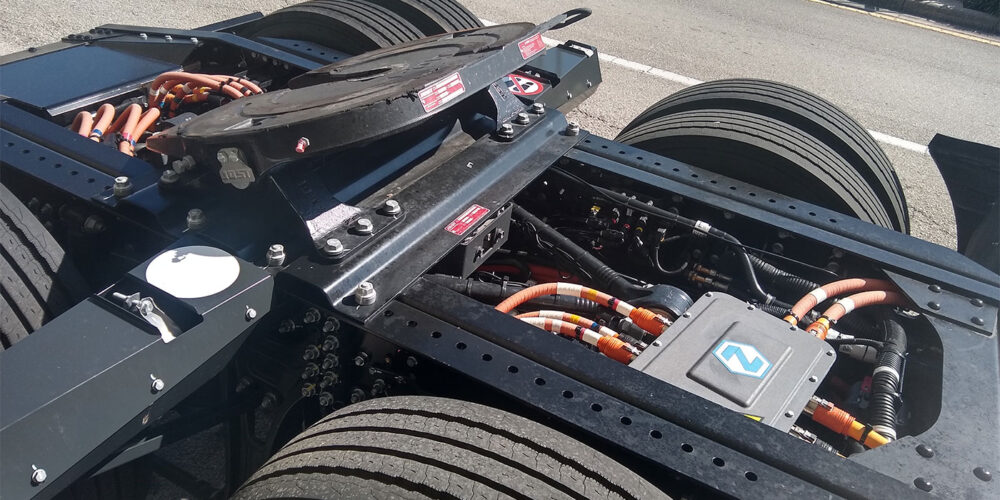

Michael Lohscheller, CEO of Nikola Trucks, watches his Class 8 Nikola Tre battery-electric truck, sporting nine battery packs for 733 kWh of energy to reach a range up to 330 miles, pull up to the front of the Orange County Convention Center, home to the TMC Annual Meeting last March. Suit coat discarded on the back of a folding chair, sleeves rolled up, he shakes the hand of a rider climbing out of the truck and holds the door for the next fleet manager in line. The battery-electric truck quietly rolls away to take another lap around Orlando.

“What’s important is that we’re in the market, we’re real, and we’re here,” he says as he sits down to talk about the future of Nikola. But first, he wants to address the elephant in the room. “My philosophy is: ‘Let’s talk about the products we have today.’ We are not announcing any new trucks in the next five years. Maybe that was different in the past. But today, we have the battery-electric truck in the market, which is a big milestone for a new company, and in the second half of this year, we will see the Class 8 hydrogen fuel cell truck.”

Nikola might be seen as a bit of a cautionary tale for a new-to-trucking company coming into the market and making big promises. No need to rehash the details of the previous administration’s mismanagement. The road ahead for Nikola isn’t about making promises, it’s about proving results.

“Demos are the best. When people experience the truck, we all learn. I think everybody gets comfortable and they say, “Hey, this is working,” he says. “They gain confidence in Nikola.”

With the Class 8 battery-electric truck in the market, Nikola has been laying the groundwork for aftersales support. For example, Alta eMobility announced an expansion with Nikola Corp. to bring electrified fleet and charging solutions into the Northern Illinois and Florida markets, which makes the all-important demo ride-and-drives available in those two new locations. The partnership also makes Alta eMobility the exclusive provider of sales and service for the Class 8 Nikola Tre battery-electric and the hydrogen electric vehicle available later this year. It expands the Nikola dealer network that includes locations in New York, Massachusetts, Connecticut, Virginia, Maryland, West Virginia, Pennsylvania, Illinois, Kansas, Minnesota, Iowa, California, Colorado, New Mexico, Texas, Tennessee, Alabama and Georgia.

“We have 42 locations in the U.S.,” Lohscheller says. “It’s all about uptime—the truck needs to drive. We have done a lot of training. We have electricians working on trucks, but the reality is that battery-electric trucks need less maintenance. Customers have confirmed a significant benefit. But we want to make sure that we have trained our service people so that, in the event that there is a problem, the customer gets support immediately.

“One of the benefits of being a young, small company is that we’re very customer and service focused. When there’s an issue, our people are there immediately. You don’t have to go through 300 different hotlines and wait three days to get support.”

One of the biggest demands of fleets as we move into zero-emissions powertrains is the need for training. Lohscheller confirmed that Nikola offers training for its customers through its service network, but he stressed the importance of the Nikola dealerships having skin in the service game.

“We have new technology, so if there is a concern, our people are out there immediately,” he said.

‘We work hard to be the first out there.’

There’s a lot riding on the Nikola hydrogen fuel cell truck, for both the company and the industry. Hydrogen has been touted as the zero-emissions solution to long-haul application demands. Theoretically, the range of 400 to 500 miles and fueling process similar to diesel (at least in the time it takes to fill the compressed hydrogen tanks) fits the bill, but as we’ve seen with battery electric trucks, “theoretically” only takes you so far when there’s a huge need for infrastructure.

“We want to build permanent hydrogen filling stations, which takes some time,” Lohscheller says. It’s also complicated because the first question is: Where are you getting the hydrogen?

“We provide hydrogen through partners,” Lohscheller says. For example, Plugis supplying us with hydrogen, and we will produce with partners, in Phoenix. We have signed a Letter of Intent with FFI out of Pennsylvania. In Canada, we get hydrogen from TC Energy.”

Then Nikola has to make the hydrogen available.

“It’s a bit of a puzzle, but we don’t have to do it all ourselves,” he says. “We look for agreements that allow us to get hydrogen at low cost for our customers. We have set up a new brand called HYLA, Hydrogen Nikola, that encompasses all of the energy products under this brand name. We will produce, distribute, and dispense hydrogen to customers, first in California. By 2026, we plan to have 60 stations in California. We have already identified four locations.”

As for the truck, it was on display at ACT Expo, outfitted with a Bosch fuel cell, an enhanced safety system from Plus, and other equipment details to come. Lohscheller positions Nikola as an “integrator,” and notes that its expertise is found in software and vehicle controls.

“That is what we do in-house, and I think that’s incredibly important because once you do the software and the controls yourself, you have all the data,” he says. “When you control that, you can quickly make updates. It’s important for us to have our software in-house.”

While all of that is on the horizon, Lohscheller has his sights set squarely on the tasks of today. In fact, he’s out of his chair before the Nikola Tre truck slows to a silent stop and opens the door for a rider who climbs out of the truck and deems it “pretty cool” before he steps to the side to pick the brain of a Nikola product manager standing nearby.

“The other point that I want to make sure that you understand,” he begins as another passenger climbs into the truck, “is that the battery-electric vehicle is for sale right now. Fleets can have one right now.”

Noted. The Nikola Tre Class 8 battery-electric truck is real, it works, and Lohscheller and his team are ready to prove it.