Most truck engines, today, run at around 1,450 RPM at cruising speed to provide the 200 HP needed at the wheel-end. Engine downspeeding allows the truck to operate consistently in a more efficient range, generally between 1,100 to 1,200 RPM, while maintaining the same 200 HP at the wheel end. As a result, fuel efficiency will increase substantially. Coming along with the increased adoption of downspeeding are new innovations related to axle ratios and other drivetrain components. Fleet Equipment asked truck original equipment manufacturers (OEMs) and axle/drivetrain suppliers to talk about changes.

Improving fuel economy

When it comes to improving fuel economy and spec’ing the best axle ratios for on-highway trucks to achieve those goals, Daimler Trucks North America (DTNA)’s General Manager of Marketing and Strategy, Diane Hames, says it all depends on the specific applications. “Currently, the most fuel efficient rear axle ratios available in DTNA products are the 2.41 ratio in a 6×4 and a 2.28 ratio in a 6×2 configuration.”

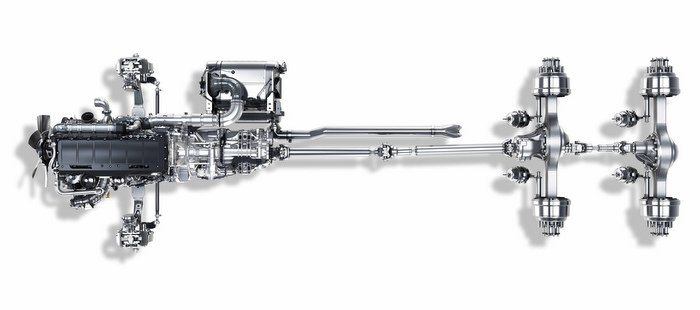

She goes on to note that some configurations can appear to be at the end of the laws of physics, but adds, “Our engineers make sure we avoid drivability factors. I think we’ll see even faster axles ratios in the future and we’ll see changes in drivelines in the future. For instance, there is a new heavy-duty RPL35 driveline for powertrain packages with a direct-drive DT12 with axle ratios 2.28 and faster.”

As for a preferred spec, Hames says the DTNA products that offer the Integrated Detroit Powertrain have the option of a 6×4 with a 2.41 ratio and 6×2 with a 2.28 or 2.41 ratio. In addition, the company has just released the Meritor 14x 2.47 ratio as an option for a powertrain package in a 6×4.

When asked if there are concerns about long-term stress on drivetrains related to increased torque, Hames responded, “We’re looking at some of the solutions to this problem, which are currently available in the market, but we’re not convinced that the current drivelines aren’t up to the task.” She adds that with the continued acceptance of automated manual transmissions, downspeeding is better enabled.

“However, with this technology another question may be ‘how low can we go?’ Continuing to move the torque curve is easier with larger displacement engines, like the DD15,” Hames continues. She adds that the DD15 gives a lot of runway, but that’s where the solutions may reach the limits of physics.