“Meritor is able to work collectively with fleet owners and truck OEMs to incorporate their feedback and performance requirements into our product portfolio,” he says. “Through the recommendation of axle ratios and driveline specifications we are able to ensure that the products available for these customers will help them achieve the greatest fuel efficiency and best overall vehicle performance.”

Mayer adds that if drivetrain components such as rear drive axles and drive shafts are not properly sized for the application, there could be concerns about long-term stress on the drivetrain. However, appropriately selecting drivetrain components that comply with the component supplier’s guidelines for the intended use of the truck will result in long-term reliability.

“The single most important factor with identifying a downspeeding solution is to select the drivetrain components that are appropriate for the intended use of the truck,” Mayer notes. “If the truck’s only use is for line-haul/long haul service the selection of fast axle ratios and direct drive transmissions may be an effective strategy for fuel economy,” he says. “These fleets should have the following traits: GCW of 80,000; annual mileage of 60,000 or more; highway driving at least 80% of the time; 30 miles between start and stops; and they should spend 80 to 90% of the time in the top two gears over smooth terrain.

“However, if the truck is used as a city delivery service or in a split service, line-haul/long-haul by night and city delivery or pickup and delivery service by day, than the selection of drivetrain components as well as axle ratios and transmission combinations must be sized for the more demanding city delivery and pickup and delivery service.

“No one size fits all,” Mayer adds, “therefore, no one-truck spec is right for all applications. The fleet should work first with the OEM to spec the right combination, while seeking advice as needed from the engine, transmission, and rear axle supplier for fine-tuning performance.”

Long-term stress

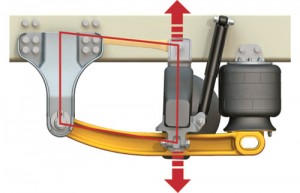

“From what we understand, there are concerns by some of the axle manufacturers on drivetrains having to adapt to different engine/transmission strategies that result in lower cruising speeds,” says Collin Dinsmoor, director of engineering, powered vehicle systems for SAF-Holland. “What can happen is that the torque/speed relationships all are driving to what happens at the tire/ground interface. Suspensions have to deal with and respond to torque inputs at the tire. This may lead to greater torque fluctuations at the tire, which can cause similar responses in the suspension. Our parallelogram design suspension systems [pictured above] are equipped to handle tire/ground torque fluctuations. These torque changes input forces to the joints that join the axle to trailing arms of torque reactive suspensions.”

He goes on to say, “In parallelogram suspensions, like ours, the joint of axle and trailing arm beams don’t pass torque directly into axle joint fasteners, the trailing arm beams, and axle housing but are reacted by both upper and lower control arms which have great leverage to distribute and lower forces.”

Dinsmoor adds that should there be and increase to downspeed for fuel economy there may be an increased need driven by maintenance and reliability.

“In our design,” Dinsmoor says, “the upper and lower arms are spread apart from each other to handle the axle torque changes. As a result, the forces are lower and less damaging to the components.

“Simply put, on-highway tractors usually have very simple torque reactive suspensions due to the nature of their usage. This downspeeding trend is driven by fuel economy geared at on-highway tractor/trailers,” he says. “Torque reactive suspensions will be more challenged by torque fluctuations that may occur with drivelines optimized for the lowest possible cruising speed for fuel economy. Fleets may want to consider using products like these to ensure that the gains in fuel economy aren’t offset by maintenance and reliability.”