What started as a one-way conversation—data streaming off of your trucks to your telematics dashboard—is now a two-way heavy-duty dialogue. Over-the-air (OTA) engine reprogramming is sending data to your trucks via cellular networks to improve their efficiency and productivity. And this functionality is only the beginning.

“What I’m excited about is that, with over-the-air updates, we’re be able to improve the truck remotely,” said Mark Curri, senior vice president of uptime and customer support with Volvo Trucks North America. Curri sat inside the Volvo Trucks Uptime Center, a 123,000-sq.-ft. support call center, where a team of customer support specialists are available around the clock, every day, reaching out to customers when they see a fault code roll into the Volvo ASIST web-based telematics portal via Volvo’s Remote Diagnostics capabilities. The Uptime Center has been operational since 2014, but what Curri is talking about takes Volvo’s approach to the service process one step further.

“Being able to reach out to the truck remotely is a big deal,” he said, “to tweak the truck to what the customer needs for their application. So if, tomorrow, diesel fuel gets really expensive and they want to govern their trucks down by three miles per hour, our trucks can do that remotely. That’s cool.”

Very cool.

But before we get ahead of ourselves, you have to be comfortable with the remote update process and understand why it’s important to take care of as soon as there is an update.

What is it and how does it work?

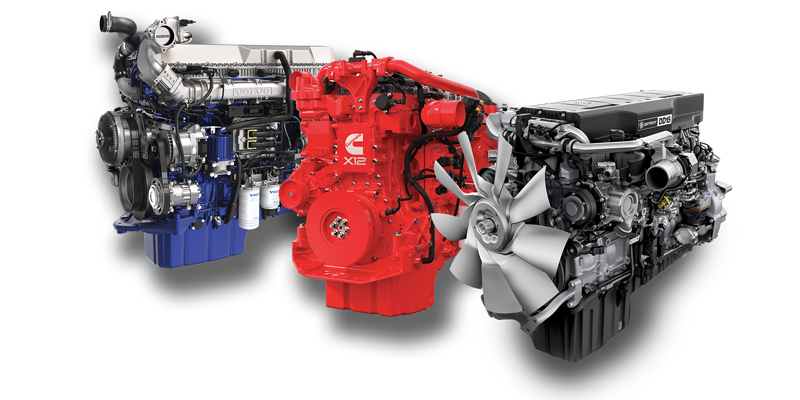

OTA reprogramming lets you send an update to your truck when it’s off duty to refresh specific parameters that vary depending on engine manufacturer. This functionality is currently offered by Detroit, Mack and Volvo. Cummins stated that the functionality is coming “soon,” and International currently offers Wi-Fi updates with OTA cellular functionality coming online later this summer. Once the engine is updated, it will operate according to the new parameters. The most common use of this technology is to patch the engine with an OEM update.

“When an update is available, a fleet manager is notified and can approve the update to one or multiple vehicles. The driver or operator will need to approve the install and be sure they are in a safe environment with the vehicle stopped (two-way approval process). Data is encrypted for secure transfer and storage of customer information.”

—Anuj Shah, Cummins

“Over-the-air programming technology enables customer uptime while improving reliability for Cummins-powered equipment,” said Anuj Shah, senior marketing communications manager for the digital accelerator group at Cummins. “Within a span of minutes, Connected Software Updates can update engine control modules using cellular or Wi-Fi connectivity.”

Engine manufacturers are beginning to offer engine parameter updates—fields such as max cruise speed and idle shutdown timer, to name a few. These are parameters that you, the fleet manager, can set and update remotely. You click a button from your engine OTA portal and the update goes into effect in the selected trucks out on the road (following the proper update procedure, of course). Within Detroit Connect Remote Updates cellular-based service, for example, parameter changes, Detroit Diesel Electronic Control (DDEC) downloads and powertrain firmware updates can be made securely via the Detroit Connect portal at any time, anywhere there is a cellular connection.

“The parameters that can be changed include road speed limit, cruise speed, idle shutdown by time and idle shutdown by temperature [high and low],” confirmed Lauren Attinasi, Detroit Connect’s manager of connectivity product strategy. “Fleets can make over-the-air parameter changes on one or more trucks, of their choosing, across their fleet and download DDEC reports without having to physically touch the vehicle. Detroit Connect Remote Updates will also soon be able to perform firmware updates over the air on all new Cascadia trucks.”

This is the part of the process that you can leverage to drive efficiency gains. Volvo, for example, offers a Parameter Plus subscription package, which allows for up to 50 parameter updates annually per covered vehicle and includes more 250 updates in categories including road speed, cruise control, transmission, idle shutdown and fuel economy. Updates are also bundled in parameter packages, such as its “comfort shift” parameters package, which provides smoother launches when load shifting must be minimized, according to the OEM.

“With two-way communication, we now

—Andrew Dondlinger, Navistar

have capabilities to manage a fleet in ways we have yet to discover. Navistar’s cellular-based solution, to be introduced this summer, will include features to modify the configuration of the vehicle based on company and/or driver needs.”

Cummins parameter functionality, when launched, will include a new application for over-the-air trim parameter calibration, which allows you to configure factory settings to meet your fleet’s unique power and fuel optimization needs.

“Cummins will offer suggested configuration templates to customers as a starting point to achieve specific requirements such as a percentage of fuel savings,” Shah said of Cummins OTA Programming (OTAP) functionality. “OTAP eliminates the need to schedule service stops to update engine control module software—which boosts productivity and reduces cost. By integrating with Cummins OTAP suite, customers will be able to take advantage of new upcoming functionalities that include trim parameter calibration, for fuel efficiency and customizable performance configurations.”

Why are engine updates important?

The answer is two-fold: productivity and efficiency. Productivity improvements can be seen through the reduction in fault codes. Yes, you read that correctly—updating your engine’s software can reduce the number of fault codes that you will deal with. Get a notification that an update from the OEM is ready, click to send it to your trucks, the driver follows the OEM’s update procedure and: poof! Goodbye fault codes.

Okay, it’s not that simple, but it’s just as magical. Here’s Navistar’s Andrew Dondlinger, vice president of general manager connected services, with an explanation:

“For example, if fuel injectors were improperly configured, they could overheat. If not corrected, it could result in vehicle downtime and damage to the fuel injectors. A simple ECM update can recalibrate the fuel injectors and result in a more efficient and reliable vehicle. There are also ‘Service Immediately’ faults associated with this issue. Once the calibration is complete, the faults no longer appear on the dashboard.”

Feel free to read that paragraph again and let it sink in: There’s a mechanical issue with the truck. An update is applied, remotely over a cellular network (just like the way your phone is updated), to the ECM and the actual operation of the engine is changed for the better. It’s not just removing a fault code—it’s fixing a service issue before it happens.

Now you can really see why Volvo’s Curri was so excited. In fact, Conal Deedy, Volvo Trucks’ director of connected vehicle services, recounted a similar situation that first showed off the power of engine updates when a few Volvo trucks powered by Volvo engines were throwing a curious turbo-

related fault code. Trucks rolled into service centers, turbos were checked, everything seemed fine—turbos operating within the parameters—and trucks hit the road, only to throw the fault again.

That’s when the Volvo team took a look at the routes the trucks were running on the Uptime Center screen that shows the position of every Volvo truck with a fault condition. They noticed that the trucks throwing that turbo-related code were running high-altitude routes through the Rockies. The turbos were performing normally, but the parameters were too constraining for the thin Colorado mountain air.

Volvo updated the turbo parameters, pushed out an engine update and the fault code stopped tripping.

If that wasn’t reason enough to put engine updates on the front burner, there are also efficiency benefits. It’s difficult to put a number on typical efficiency gains due to engine updates, but when you combine it with the service-reducing productivity gains, any additional efficiency is a boon.

So how do you do this?

Each engine manufacturer has its own process for updating its engines remotely. We have detailed that here:

Beyond the actual updating process, what is required of you and your fleet is a change in perspective, perhaps even culture.

“Fleets are eager to recognize the gains of efficiency with remote updates but have to work through adopting the technology in their operations,” Detroit Connect’s Attinasi said. “Some fleets have adopted smaller rollouts where personnel using the capability are well trained on the tool, while others have placed the responsibility of over-the-air updates on a small group of personnel covering cover hundreds or thousands of trucks directly. The different approaches illustrate different ways to operationalize a new technology, which has been the largest hurdle so far.”

“Software is the lifeblood of the truck’s connected components. Just like your phone, to get the optimal performance out of a truck, you should have the newest and the best software. For your application it might be different than another fleet’s software, but we want you to have the newest, and the best software potentially saving a lot of headaches.”

—Mark Curri, Volvo

How you approach the adoption of the OTA process is up to you, but know that OEMs understand your challenges and aim to help.

“Most customers purchase more than one brand of truck for their fleet, so the responsibility rests on OEMs to develop and follow these standards and best practices to serve our mutual customer,” Navistar’s Dondlinger said. “The need for standards and best practices in the telematics and programming space is enormous.”

This is a process that will impact your fleet service operation, drivers and perhaps even dispatch. Like all new technology implementation, good old-fashioned communication is going to be the key to its success. Stay focused on the payoff, not the initial growing pains. Not only will you benefit from the near instant efficiency and productivity gains, but you’re also laying the foundation to leverage growing OTA functionality.

“In the future, additional remote updates will allow rapid performance updates to key systems and customization for fleets and drivers including in-cab displays, climate controls and advanced driver assistance systems [ADAS] systems,” Attinasi said. “As vehicle technology becomes more sophisticated and evolved, the ability to remotely update software and settings will present customers with not only efficiency gains but a new level of flexibility in asset deployment and driver engagement.”

Time to get upgraded.

For more on this topic, check out OTA power to the third-parties.

Check out the rest of the July digital edition of Fleet Equipment here.