Accuride introduces Gunite lightweight brake drum

Accuride Corp. announced the introduction of the Gunite Silver lightweight brake drum. The new 4000X drum is a full-cast brake drum that offers a 12.5-lb weight savings over standard full-cast drums.

Accuride expands manufacturing

Accuride Corp. announced plans to expand its Henderson, Ky., plant. The company is investing $5.8 million to expand its powder coating capacity with the installation of a new coating line at its steel wheel production facility.

Accuride adds Accu-Armor aluminum wheel surface treatment

The company’s Accu-Armor treatment makes aluminum wheels highly resistant to scratching and scuffing, filiform corrosion, high- and low-pH chemicals commonly used in truck washes, and common chemicals used in de-icing road surfaces.

Accuride renews aftermarket commitment through investments

Accuride Corp. announced its renewed commitment to the aftermarket, including a $75 million investment in 2012, an intensified regional sales approach, the creation of a distributor advisory council, and regular customer visits by management team members every 90-120 days.

Accuride increasing North American capacity, capabilities

Accuride Corp. will invest $75 million in 2012 to strengthen product availability, quality and reliability; upgrade its manufacturing processes; and improve customer service. The first phase targets new machining lines and related equipment in the wheels business, while a second phase involves improvements at Accuride’s gunite operations.

Accuride adds aluminum wheel capacity in Mexico

The company has completed its initial expansion of aluminum wheel production capacity at its Accuride de Mexico facility in Monterrey, Mexico. The 226,000-sq.-ft. facility was built in 1999 and employs approximately 400 people.

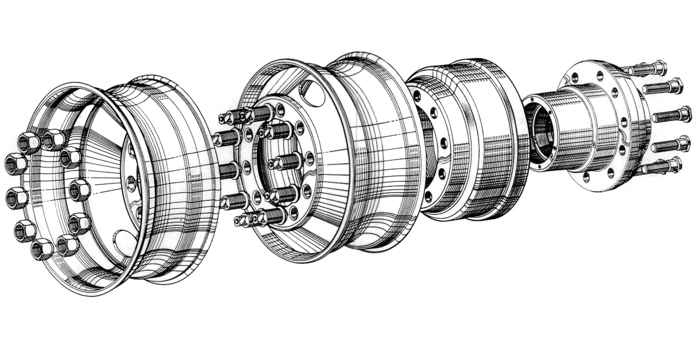

Inside wheel ends: How slack adjusters could raise wheel end temperatures

Wheel end thermal events are serious maintenance issues that can be caused by setup, maintenance, driver neglect, road debris or some combination of all of these. Before we look at how slack adjusters may factor into higher wheel end temperatures let’s get this out of the way first: Each wheel end thermal service event needs

What’s the difference between clearance-sensing and stroke-sensing slack adjusters?

“Clearance-sensing slacks adjust to produce a consistent gap between the face of the brake pad and the braking surface of the drum,” said Greg Sturdy, director of wheel end product engineering for Accuride Corp. “Stroke-sensing slacks adjust to produce a consistent distance the pushrod of the brake canister is allowed to move.” Like any component,

Navistar announces winners of its ‘Diamond Supplier’ award

Navistar Inc. has announced the winners of its annual Diamond Supplier Award, given to the company’s highest-performing suppliers. “We strive to create products that have excellent quality and uptime,” said David McKean, vice president of procurement for Navistar. “The suppliers receiving this award have proven to us that we can count on them to do the job, and do it

The unsung heroes of wheel end maintenance

What is more important to proper maintenance of tire/wheel and wheel end assemblies? A calibrated torque wrench, or an oil can and a wire brush? Sure, lots of factors affect component performance at the wheel end. Is the mounting surface clean and free of rust? Is the wheel free of corrosion brought on by harsh