MEMA Aftermarket Suppliers announces appointments to Heavy Duty eCommerce Committee

The HDeC, according to the press release, was established in 2023 to engage in matters related to the business benefits of advancements in eCommerce.

Preventive maintenance truck tips for automatic slack adjusters

Time and miles: Both seem to roll by more quickly than we realize. Consider six months, 1,800 operating hours, or 50,000 miles – for many working trucks and truck drivers, those aren’t long intervals: But they’re key markers for a piece of basic wheel-end preventive maintenance that’s too often overlooked. This installment of the Bendix

Making Fleets Safer With Advanced Technology

Every fleet and every driver wants to operate in a safe manner. All you have to do is look at the number of drivers honored each year for a million or more accident-free miles. And while driver skill and ability play a large part in a fleet’s safe operation, today’s advanced driver assistance systems (ADAS)

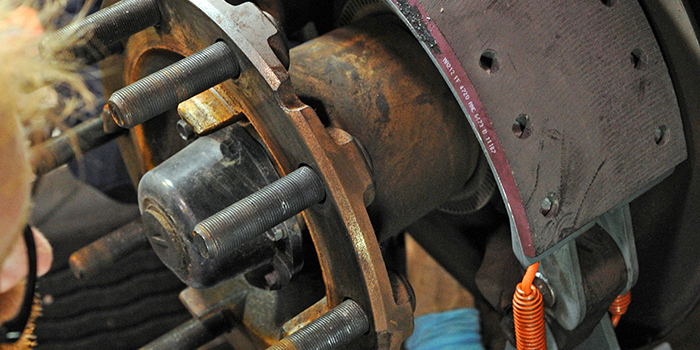

Brake maintenance myth: Adjust the slack at every inspection

For fleets and drivers operating vehicles equipped with automatic slack adjusters (ASAs): Do not manually adjust the ASA if the brake is beyond the stroke limit. It’s sound advice from Bendix Commercial Vehicle Systems and Bendix Spicer Foundation Brake (BSFB). Some technicians servicing drum brakes will adjust ASAs at every PM inspection. Properly installed, operating

Common wheel-end service misconceptions

In servicing commercial vehicle wheel-ends, fleets and operators sometimes rely on industry practices that are accepted, trusted—and may no longer be valid. This installment of the Bendix Tech Tips series from Bendix Commercial Vehicle Systems LLC and Bendix Spicer Foundation Brake LLC (BSFB) addresses five common misconceptions, offering the facts behind each to help industry

Preventative maintenance to avoid CSA brake violations

There’s a lot to remember when inspecting brakes; fleets need to make sure everything is operating properly, and that potentially costly CSA violations can be avoided. Fleet Equipment polled our experts from our CSA brake story on the steps they recommend taking in a brake inspection. Read the full story on common issues that lead to CSA violations,

Check your brakes: Putting a stop to brake-related CSA issues

Commercial Vehicle Safety Alliance’s CSA violations should be an unnecessary problem, especially since they can lead to costly delays, and unexpected downtime may cause fleets to lose customers not only because of delays. After citations related to lighting problems, brakes are the second most commonly penalized item—18.7% of violations handed out by the CVSA in

Applying the brakes: Ensuring the future of truck safety

Advanced safety systems that employ radar- and camera-based technologies that enable adaptive cruise control and even autonomous truck operation rely heavily on one specific component—the brakes. The safety of these futuristic collision mitigation systems rests squarely on proper brake application, operation and maintenance. “It’s important to keep in mind that advances in collision mitigation technology

Freightliner Bose Ride, SmarTire TPMS options roll into Cascadia production

The Bose Ride system II truck seat suspension and the SmarTire Tire Pressure Monitoring System (TPMS) from Bendix CVS are now in production for the Freightliner Cascadia and Cascadia Evolution truck models. Introduced in early 2015, the Bose Ride system II truck seat suspension features new technologies designed to reduce fatigue and pain. The system uses

The importance of tire pressure monitoring

Keeping a close eye on tire pressure can also impact your bottom line. Under-inflated tires flex excessively under load, producing heat and increasing rolling resistance, which wastes fuel. Tires inflated 10 PSI below recommended levels can reduce truck fuel economy up to 1%. In addition, stress from flexing causes fast and uneven wear, shortening the