Western Star offers Neway ADZ suspensions

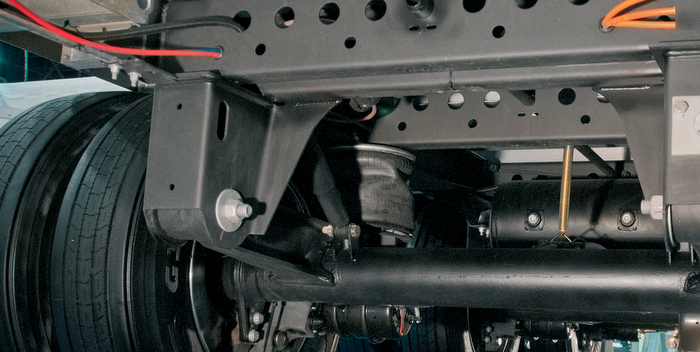

Western Star Truck Sales Inc., is now offering Neway ADZ Series heavy-duty drive axle air suspensions by SAF-Holland as an option for Western Star 4800, 4900 and 6900 truck models. The ADZ Series suspensions feature a streamlined design that has reduced weight by more than 220 lbs. per axle (compared to previous models). The new,

Spec’ing suspensions and lift axles to meeting bridge formula laws, improve durability

Enacted by Congress in 1975 to limit the weight-to-length ratio of a vehicle crossing a bridge and to provide a consistent way to determine the maximum allowable weight that any set of axles on a vehicle may carry on the Interstate highway system, the Bridge Formula has had an impact on axle and suspension design

Selecting lighter-weight suspensions

Selecting the correct suspension system can go a long way in both fuel efficiency and weight savings. If the correct suspension is paired with the proper powertrain, you can have gain efficiency without putting on the pounds. SAF-Holland offers the Neway suspensions. On the drive suspension side, the ADZ capacities are 46,000 and 52,000 lbs.

Handling the tough hauls: What you need to know about severe-duty drivetrain, axles and suspensions

Extreme loads are no match for properly spec’ed and maintained severe-duty truck models. Vehicle OEMs, in fact, list a range of applications for which they have specific models designed to meet severe-duty needs. Included are dump, concrete, crane, roll-off body, refuse, heavy haul, logging, oil and gas field service, utility, fire and emergency, snow plow

Air suspensions explained: A fleet’s bottom line can benefit from trailer air suspensions

Trailer air suspensions offer fleets many benefits, including optimized fuel efficiency and tire life, superior cargo protection, improved ride characteristics and minimized wear and tear on trailer components. These advantages can be maximized with some basic knowledge concerning the ins and outs of air suspensions, along with a good understanding of maintenance practices. We asked several manufacturers of trailer air suspensions to weigh in on the subject, and their advice could save fleets a significant amount of time and money.

Mack debuts new suspensions with proprietary axles

Twin Y Air and mRide spring suspensions from Mack Trucks are now being offered with proprietary Mack axles. The Mack Twin Y Air Suspension is available on the Pinnacle Axle Back and Axle Forward models with S38 and S40 series axles with C125/126, C150/151 and 200 Series carriers.

Mack rolls out suspensions with proprietary axles

Mack Trucks launched its Twin Y Air Suspension, with a new Y-shaped high-strength steel design, which is offered with proprietary Mack axles. The OEM also announced the availability of Mack proprietary axles on its mRide spring suspension.

Drivetrain components: Axles, suspensions and u-joints

A number of factors are impacting axle choices by fleets, including the need for lighter weight configurations, direct or overdrive transmission choices, faster axle ratios, pending engine changes including higher torque ratings, and in some cases, lower cruise speeds.

Air suspensions: spec’ing and maintenance

When it comes to air suspensions, It’s all about a smooth ride and protecting cargo. Today, air suspensions are specified on 85% to 90% of all new on-highway commercial vehicles in North America.

Air ride suspensions protect more than cargo

Those fleets that specify air ride systems for trailers probably already know that the benefits of the systems go far beyond protecting cargo. A smooth ride helps mitigate vibration damage on the undercarriage and body of trailers and limits jarring wear on doors, liftgates and lighting systems, just to name a few, and they help