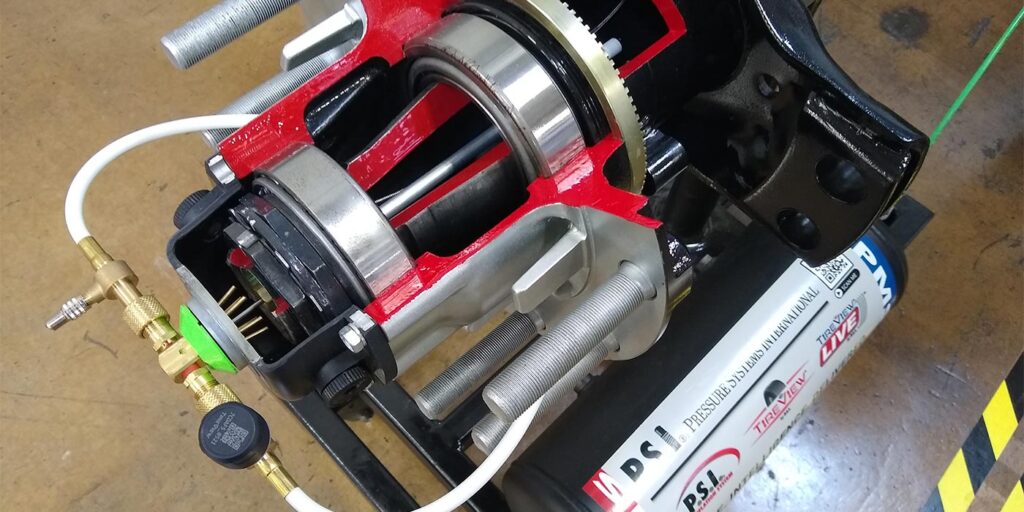

The last time we caught up with Pressure Systems International (PSI) during their annual event, it was 2019, they had just surpassed 1.5 million units in the field and COVID wasn’t a thing that most people in the world had ever heard about. Clearly, a lot has changed, but one thing has remained constant: PSI has kept pushing forward, with more than 1.8 million Meritor Tire Inflation Systems now working out in the wild.

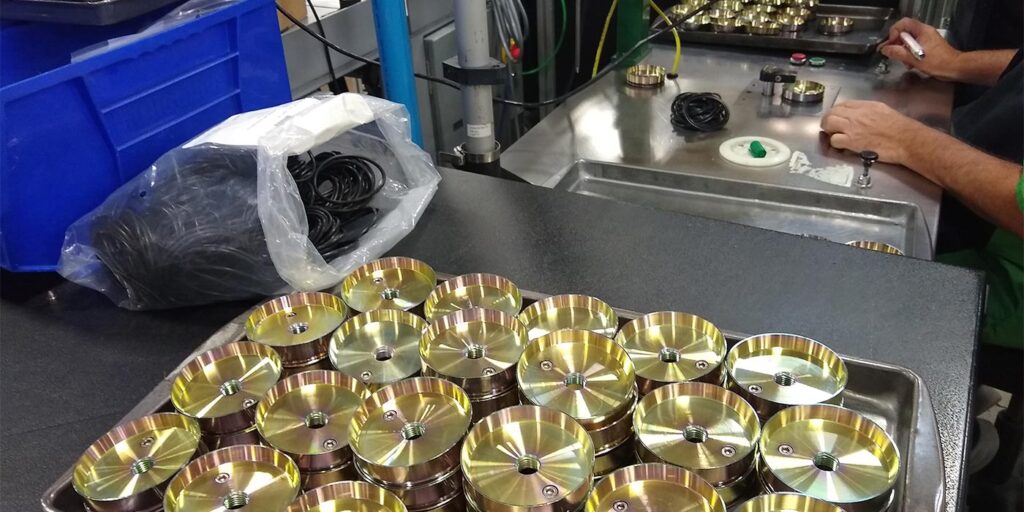

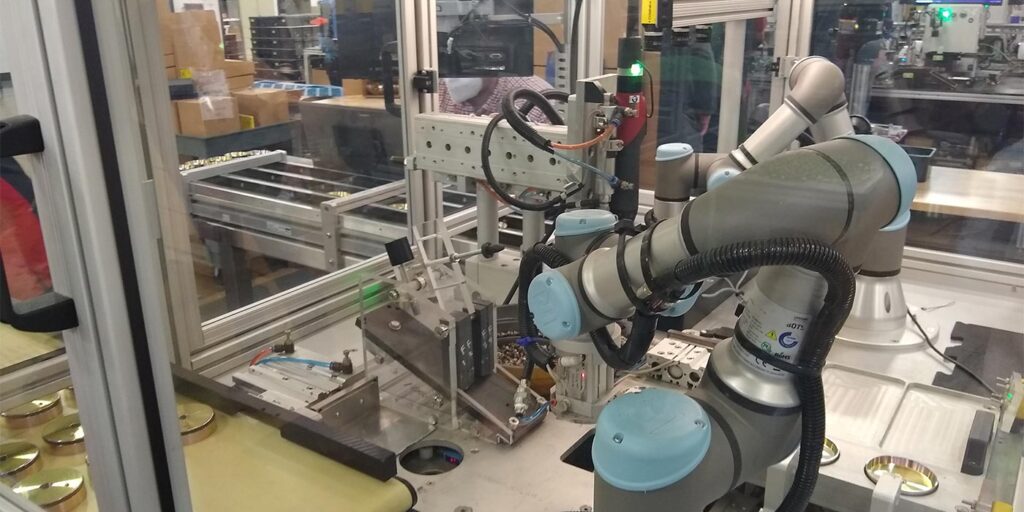

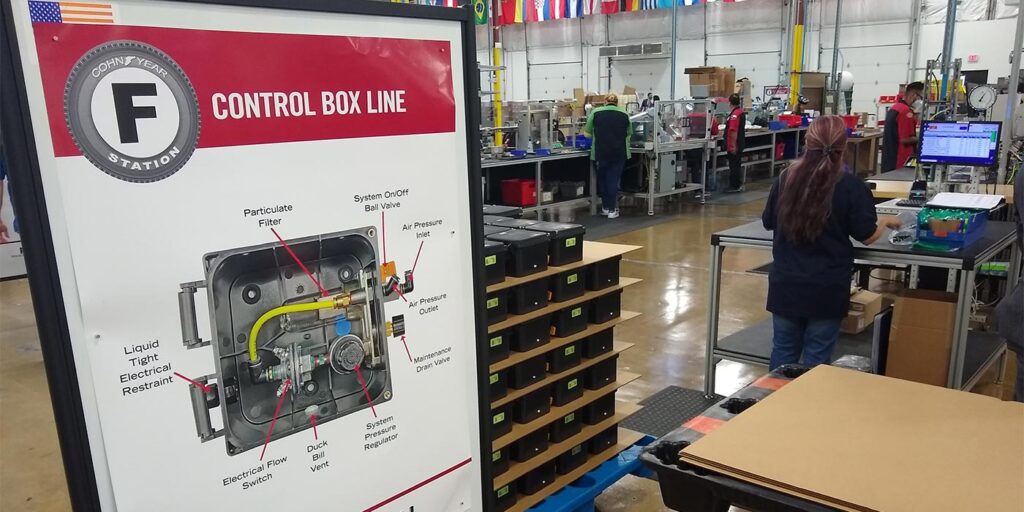

On a personal note, I hadn’t been to the PSI HQ in six years and while the company’s manufacturing focus is still squarely set on quality people producing quality equipment, there were definite changes on the line. Robotics and automation is finding it’s way into PSI’s traditionally hand-made automatic tire inflation systems. Make no mistake, there are still plenty of people there touching the product. The new level of automation replaces manual labor tasks that wore on their workforce. During the tour, there was no shortage of “no way we’re going back to the old ways” from those on the line.

So take a visual walk down the PSI manufacturing line with this gallery and click here to read about how PSI is pushing its technology forward in our event coverage story.