To keep your business moving forward, you need to be able to service or rebuild commercial vehicle drivelines as efficiently as possible. Choose a preassembled kit for your next rebuild, and stop wasting time and money ordering and stocking individual parts.

From shipping the goods we want across the country, to delivering food, to public transportation, commercial vehicles drive our way of life. And in commercial vehicles around the world, the hardworking drivetrain system enables the rig to shift from idle to drive and helps power the vehicle down the road. Promptly and properly servicing or rebuilding these drivetrains in the most efficient way possible—including the driveshaft, universal joints, and related components—prevents the failure of other parts, and keeps commercial vehicles rolling down the road to support your business and our economy, day in and day out.

Since most trucks and buses are rear-wheel drive, it’s likely that your team works with this type of drivetrain regularly. To break down the drivetrain system of a rear-wheel drive vehicle, there’s the long driveshaft that connects via universal joints to the transmission on one end, and runs along the length of the vehicle to the rear differential on the other end, making the back wheels turn. The driveshaft, which may rotate at three to four times the speed of the vehicle, is clearly an integral part of the system. If it begins to fail, a driver may have difficulty controlling the vehicle.

While that may all be common knowledge, did you ever stop to consider how important the universal joint can be to avoiding downtime and maintaining driver safety? While there are several common indicators of a failing driveshaft, the fact that many of them are linked to the u-joint and its related components highlights the crucial importance of a reliable u-joint assembly.

When a driver reports feeling a forceful shaking and vibration from underneath the vehicle, this is one common indicator of a driveshaft assembly with worn u-joints. While of course issues with the tires can also cause vibration problems, those vibrations are generally speed-sensitive. In the case of a worn u-joint, the bearings may be so damaged that the driveshaft is moving outside of its typical rotational path, creating imbalance and vibration.

The dreaded clunking noise when shifting can be another sign of driveshaft damage; a deteriorating u-joint is often the problem here as well. If a vehicle shudders when accelerating, a loose u-joint could be at fault. Yet another concern is a squeaking noise when the vehicle is at low speeds, which is often a warning of insufficient grease in the u-joint. If any of these issues are present, failure to service or correctly rebuild a driveshaft and its related components can lead to the damage of other drivetrain parts. And no one wants the downtime associated with a broken u-joint, as it will disable the vehicle and likely ruin the driveshaft.

To zero in on the causes of a failing u-joint within a driveshaft, you can bet on three main issues to trigger virtually every u-joint failure. These are operating beyond the maximum design angle, bearing contamination, and a breakdown or lack of lubrication.

Greaseable u-joints are more likely than non-greaseable u-joints to suffer from a lack of lubrication. Even if their seals don’t leak, these u-joints must be greased regularly. If the lubrication begins to break down, wear to the rollers and the u-joint cross can occur, producing slack in the joint and a “clunk” when power to the driveshaft is reversed. Non-greaseable u-joints such as certain Spicer Life® Series (SPL®) u-joints are packed with grease in the factory and sealed for life, so they often last longer than u-joints with a grease fitting.

Contamination is perhaps a bigger problem than lack of lubrication. While some u-joints are designed to be re-lubricated, it is simply not practical to take apart and clean any type of u-joint. Though any u-joint can become contaminated, it’s more common that water and mud may get past the seal in u-joints with a grease fitting, or zerk. Either way, once contamination occurs, it is likely that the u-joint will eventually fail.

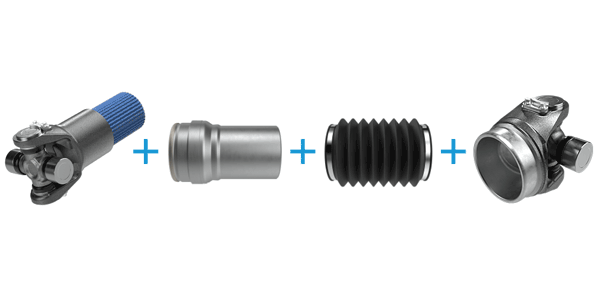

Since the whole drivetrain system must work as a unit, it’s clear that choosing the highest quality parts for a rebuild or repair is essential to getting a vehicle back on the road—and keeping it there for the long haul. So it might go without saying that the u-joint and its assembly must be carefully considered. The all-important u-joint is featured on either end of the driveshaft: in a yoke shaft on the slip joint, and in a tube yoke on the tight joint. These parts installed together correctly, along with a boot kit and splined sleeve assembly, are what keeps the driveshaft turning smoothly.

However, ordering and keeping inventory of all the individual components related to the u-joint can be frustrating if you are performing frequent driveshaft rebuilds or repairs. There is a solution: Spicer ReadyPack™ preassembled kits for commercial vehicle driveshafts, coupling shafts, and interaxle shafts. Spicer ReadyPack preassembled kits arrive with u-joints that are professionally installed in the yoke shaft and in the tube yoke—saving you time, labor, and cost on your rebuild. In Spicer ReadyPack kits for the SPL® series, the SPL® u-joints are already packed with production grease and sealed with the multi-lip seal. Across the board, the parts are as good as or better than the OE parts they replace. With Spicer ReadyPack, you’ll also see a 5% savings compared to purchasing the kit components individually, and a reduction in installation-related downtime of 15-30 minutes!

The time for a service or rebuild of the driveshaft and related components depends on how hard, and in what conditions, a vehicle is driven. Being alert to the warning signs of wear can help prevent extended downtime due to damage to other parts, such as the transmission and the rear differential pinion bearings. And when it’s time to rebuild or service, choose a preassembled kit to further boost your efficiency and get back on the road quickly and reliably.

For more information on Spicer ReadyPack preassembled kits or any other Spicer driveline product, visit SpicerParts.com.

This article was sponsored by Dana Incorporated.