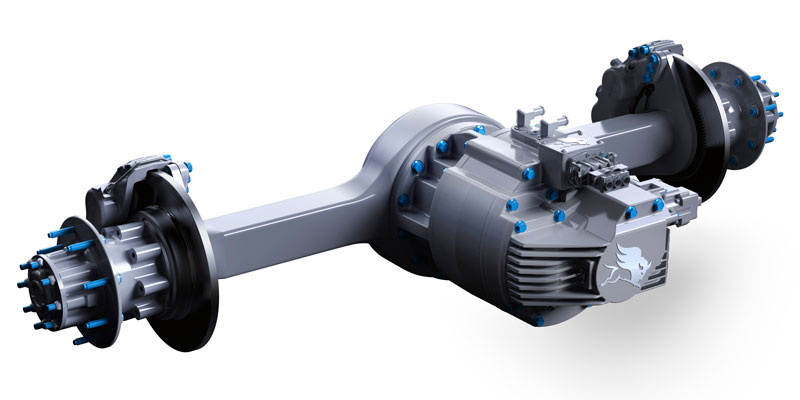

With no engine to speak of, the electric vehicles of the future (and, increasingly, the present), need a source of propulsion. Electricity may be the truck’s fuel, but it can’t move the vehicle forward any more than diesel can in conventional trucks; something has to fill the gap left behind by the engine’s absence. In many electric trucks, it’s the axle that must bear this burden.

Axle manufacturers have been working on eAxle solutions for years, from the Dana axle used on Hyliion’s 6X4HE hybrid electric system (announced in late 2017) to the recent announcement that the AxTrax eAxle from ZF powers the Freightliner Innovation Fleet eCascadia. In the time since these and other existing products came about, engineering innovation has only increased. So FE decided to check in with the makers of electric axles to see where these axles are now, and where they are going.

“Designed as a drop-in replacement for existing axles, electric axles continue to evolve, accommodating full electric medium-duty truck and bus applications, and long-haul hybrid vehicles,” Steve Slesinski, director of global product planning for Dana, explains. Dana’s Spicer Electrified series is supplied for electric buses in China and in trials on Isuzu N-Series chassis, in addition to Dana’s work on the aforementioned Hyliion solution.

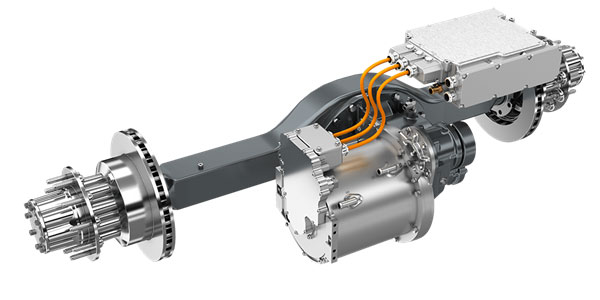

“Inclusive of a gearbox and motor, eAxle development has focused on improving design flexibility for battery placement and truck body positioning,” he goes on. “The eAxle incorporates the torque and power conventionally handled by the engine, transmission and driveshaft into a smaller and lighter package space.”

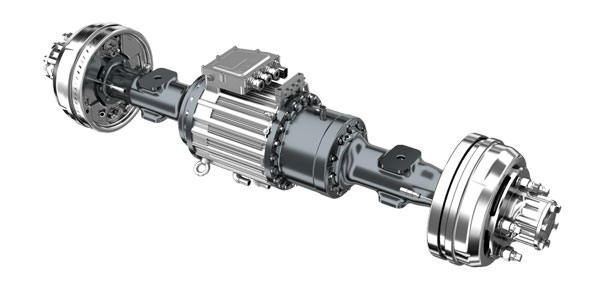

Matt Thorington, principal calibration engineer for powertrain solutions with Bosch, lists three major benefits of eAxles:

“eAxles can enable higher overall driveline efficiency by reducing gear losses, especially when removing inefficient hypoid gears. eAxles can also offer more packaging space in the chassis for other key battery electric hybrid components such as battery packs. Lastly, eAxles can be easier for the OEM to integrate due to the reduced number of separate parts, increasing serviceability for fleets.”

Bosch’s work on electric axles is ongoing and includes co–development of eAxles for the forthcoming Nikola One and Two hydrogen fuel cell powered trucks.

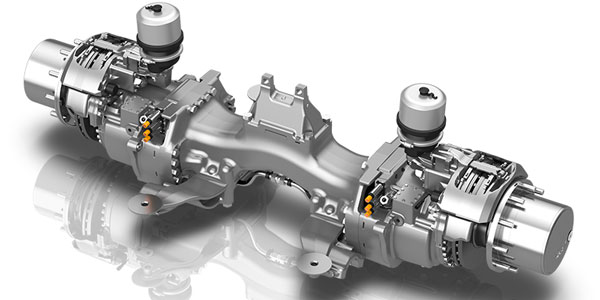

“ZF started high volume production of eDrives in 2008 with hybrid transmissions for car applications and later electric axles for BEV city buses,” says Christian Feldhaus, head of truck and van driveline technology for North America with ZF. “Currently the industry is in an interesting phase, where many OEs are not only exploring electric central drives but also full electric axle concepts. The ZF electric drive axle AxTrax offers zero emission driving with maximized performance and minimal noise emission, ideal for battery electric vehicles, hybrid drives and fuel cell technology. It gives trucks the option for efficient entrance into zero-emission city zones.”

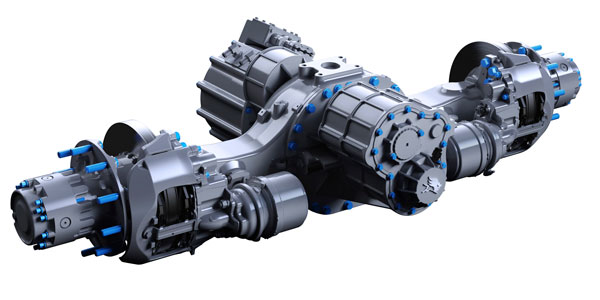

“Meritor has made significant progress in electric axles from proof of concept to a validated solution that is nearing production,” says John Bennett, vice president and chief technology officer for Meritor. “Our eAxles have completed 100% lab validation and internal vehicle testing and are now undergoing field testing with vehicle OEMs and their customers.”

Bennett goes on to say that Meritor’s ePowertrain product portfolio has recently been expanded to include the new 12Xe and 17Xe ePowertrains.

“The 12Xe is built on the modular design of our existing 14Xe, while the 17Xe is a new ePowertrain architecture specifically designed for heavy 4×2 vehicles. We have also added a three-speed transmission option available for high performance applications,” he says.

The future

What will tomorrow’s eAxles be able to do that today’s cannot?

Demand for eAxles will only increase as electric vehicles become more prevalent in the years to come. Dana’s Slesinski says that, at first, Dana believes this interest will predominantly be confined to light- and medium-duty commercial vehicles and buses.

“Our eAxles will continue to advance in terms of their level of power density, size, NVH reduction and simplicity,” he says. “Designs that include robust solutions for high powered cable attachments, and that appropriately handle the long-term abuse associated with unsprung mass conditions of axles at highway speeds and other duty-cycles, are being thoroughly validated.”

“Vehicle manufacturers are in the process of validating integrated eAxles, specifically around the packaging benefits and weight advantages compared to a remote motor solution, which is a common offering,” Meritor’s Bennett says. “Furthermore, there is the continuation of proving the technology maturity and reliability, what will effectively drive adoption of electric powertrain solutions.

“Our goal is to provide a value proposition that benefits our customers. Integrated eAxles deliver enhanced efficiency and an optimal battery packaging solution,” he adds. “We also aim to bring to market eAxles that are modular and serviceable, thereby leveraging common parts and capabilities.”

“Shortly, ZF will announce a new product portfolio for light to heavy commercial vehicles with a revolutionized system architecture which we call the ‘Next Generation eMobility,’” Feldhaus reveals.

“The demand for electrified commercial vehicles is taking off but overall industry volumes are still small compared to conventional technology. Therefore, ZF plans to offer harmonized and modular system solutions simplifying integration, covering commercial vehicles across various classes and applications.”

“Advancements in CV eAxles will be focused on further integration of the motor in the axle, reducing packaging space and axle weight and increasing system efficiency,” projects Bosch’s Thorington. “At Bosch, we are working with several OEMs and axle manufacturers to integrate our high-speed motor technology in their eAxles, in order to take advantage of our high power density and motor/inverter efficiency. We also are supporting the scalability of the eAxles to cover a wide range of applications.”

As development continues, more capabilities of eAxles will become known. After all, axles on conventional trucks work in harmony with many neighboring parts, including the suspension, the tires and the drivetrain. It’s only natural that eAxles will do the same.

Both Dana’s Slesinski and ZF’s Feldhaus noted that future trucks can take advantage of a compact installation of the drivetrain, including by placing the entire electrical propulsion system into an eAxle. The real estate gained from this, Feldhaus notes, can be utilized for additional battery capacity, fuel cell and other electric components.

“For the foreseeable future, central mounted electric drive systems will continue as a very reliable and viable method for many battery electric vehicles,” Slesinski adds. “In these configurations, the driveshaft and axle system are specified to match requirements for the speed, torque and power requirements in a similar manner as with an internal combustion engine and transmission, but the requirements for the electric drive system are matched to a conventional axle and driveshaft designs for optimum performance and longevity.”