It is important to periodically inspect a vehicle’s wheel ends to ensure safety and maximize over-the-road performance. Inspection will help determine if a wheel end repair is necessary.

SKF recommends performing a detailed inspection of all wheel ends every 100,000 miles, or every 12 months, whichever comes first.

Before performing an inspection, always follow the manufacturer’s safety guidelines. It is highly recommended to wear safe eye protection to avoid serious eye injury, and protective clothing as needed.

To prepare the vehicle for inspection, first put the vehicle in park and block the wheels to prevent the vehicle from rolling. Then, raise the axle until the tires are off the floor and make sure that the vehicle is properly supported with safety stands. WARNING: Never work under a unit supported by only a jack. If the axle is supported with spring brake chambers, following the manufacturer’s instructions, carefully compress and lock the springs to completely release the brake.

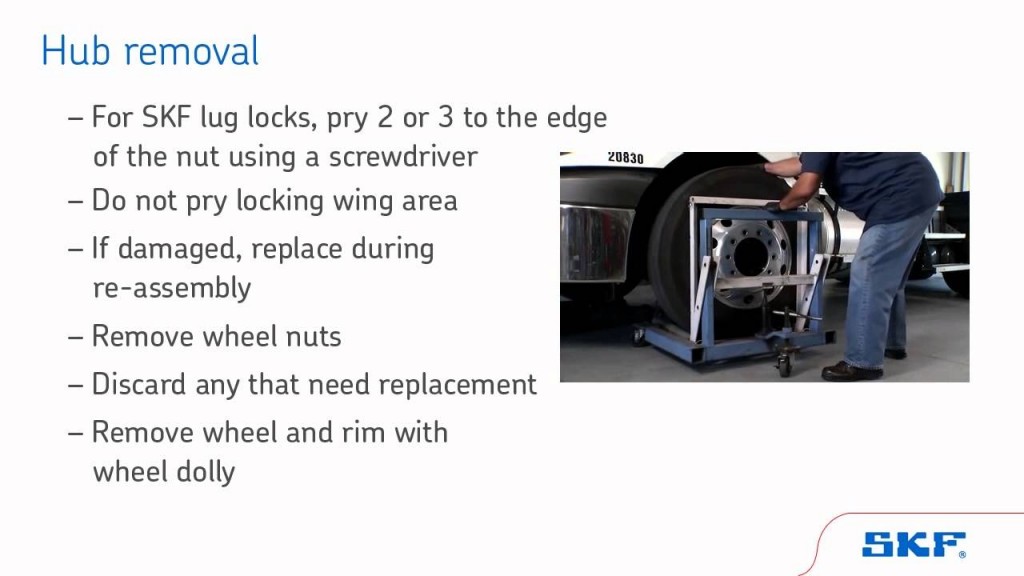

Next, using a proper hub support, remove the spindle nut and pull the hub assembly off the spindle. SKF recommends checking for the following when inspecting a spindle and hub:

1) Inspect the spindle and spindle threads for damage, and remove light fret. Also check for spalling, corrosion pits, discoloration from overheating, punch marks/chisel marks, weld beads and upset metal. Note: Damaged threads can be repaired using a pitch thread file or die nut.

2) Inspect the fastener, lock nut, bearing adjustment nut and washer. Look for chisel marks or other deformation as a sign of improper installation, or an attempt to make temporary repairs. Note: The use of these spindle end components varies by truck or trailer manufacturer.

3) Inspect the inside and outside of the hub. Look for broken fasteners and bolts, cracks in the housing, and damage to the hub and bore. Note: If the bearing cup is loose in the hub, this indicates a serious condition and the hub must be replaced.

For more wheel end inspection and maintenance tips, download a copy of the SKF TFO Wheel End Maintenance Guide (457975).