The newest remote diagnostics technology on some engines improves productivity, reduces operating costs and increases efficiencies for trucking fleets. We all know that one of the most effective ways to improve a fleet’s bottom line is by minimizing equipment downtime. New remote diagnostic technology, available on some of today’s heavy-duty diesel engines, can address that issue by saving one-half to a full day in repair time, said Jim Sweeney, vice president of capital equipment for AmeriQuest Transportation Services.

Sweeny contends that manufacturers that can successfully take cost out of operating EPA 2010 trucks will be the ultimate winners of the “truck wars.” Manufacturers are staging a counterattack on higher truck costs by using emergency technology to boost fuel economy and cut costly downtime.

Remote diagnostics programs by the manufacturers of Detroit and Volvo engines are good examples of how the engines use on-board sensors to identify engine faults. The data is transmitted in real-time to the manufacturers’ customer support centers, which analyze the data and then notify fleet managers of the nature of the problem. Drivers of trucks that need immediate service can then be directed to the closest dealer, which has been alerted and is prepared to deal with the issue. Fleets are given the choice of getting immediate attention or scheduling a repair for less serious problems at a dealership at a later time. Even in the second situation, the problem has already been diagnosed, the parts are ready, and the service bay prepared—so the downtime has been minimized, Sweeney said

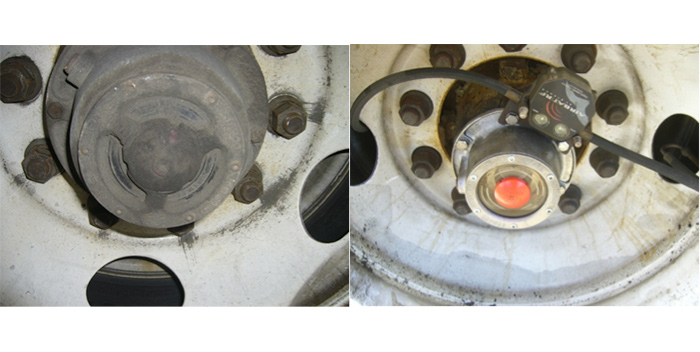

Under normal circumstances, if the check engine light illuminates, it’s up to the driver to take the truck to the nearest technician, who must then use expensive equipment and valuable time to determine the fault code and diagnose the problem, noted Daimler Trucks North America’s Detroit division. The delay between the event and service can result in even more damage. With the Detroit Virtual Technician, the information goes straight to the source the second the fault code is issued, removing delays and guesswork, the company notes. The High-Definition GPS/JBUS system, located in the truck, takes a snapshot of the truck’s status for a period of time before and after the fault code event. The information is emailed to the fleet manager and/or the dealer.

Volvo Trucks North America agrees that remote diagnostics is proven to enhance repair accuracy and efficiency. The truck maker states that Remote Diagnostics, a standard feature on all Volvo-powered trucks, reduces the average diagnostic time at a service location by 71% and lowers the average time of repair by 25%. The proactive diagnostic and repair planning service helps improve parts availability and provides technicians at the repairing dealer with easy-to-read repair instructions before the truck arrives for service. While fleets’ hands are tied when it comes to emissions regulations and the resulting higher costs of new trucks, they can improve the bottom line by minimizing equipment downtime.

This new technology is leading to improved productivity, reduced operating costs and increased efficiencies, especially for medium-sized and smaller fleets. In today’s transportation marketplace where margins already are razor-thin, the ability to reap invaluable operational information and keep vehicle downtime to an absolute minimum can be the difference between success and failure for fleet owners and operators.