Given the amount of time drivers of vocational trucks spend in their vehicles, ride quality is critical to keeping them comfortable, notes Bryan Redeker, power suspensions product manager at SAF-Holland. “Some vocational trucks spend the majority of their operating time traversing uneven and rough roads, so poor ride quality can lead to discomfort, back issues and sometimes sickness for the driver,” he adds.

Among the things that Dennis Krob, market segment manager–vocational at Hendrickson, says fleets should focus on when choosing the right vocational truck suspension include how much time is spent off road. “Other considerations are the time spent loaded vs. unloaded, the maximum loads expected and potential overload situations,” he relates. “In addition, is the application weight sensitive or does the load have a high center of gravity?”

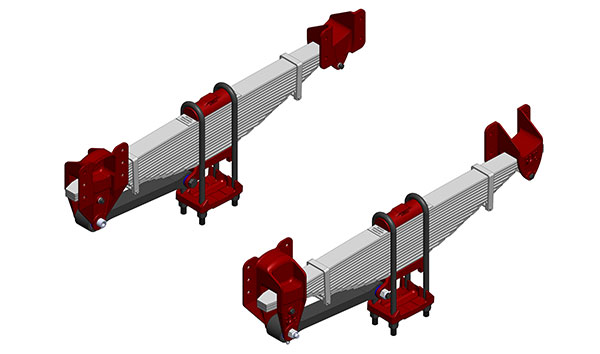

One basic choice relates to vehicle use, as John Hinz, Reyco-Granning’s vice president of engineering, notes. For example, in vocational trucks that are used at or near full capacity most of the time, a properly spec’d steel spring suspension will work very well and provide an excellent ride. Likewise, drivers of vehicles that see varying loads will benefit from a self-adjusting air suspension.

“Steel spring suspensions often have a linear spring rate, whereas air suspensions with rolling lobe air springs can have an optimal spring rate focused on comfort at ride height, delivering less energy to the driver which correlates directly to comfort,” Hinz explains further. “There is an assumption that a higher capacity suspension will be more durable and last longer but in reality an over-spec’d suspension transmits far more energy into the chassis of the vehicle, which contributes to a rough ride, driver discomfort, damage and even unsafe conditions.”

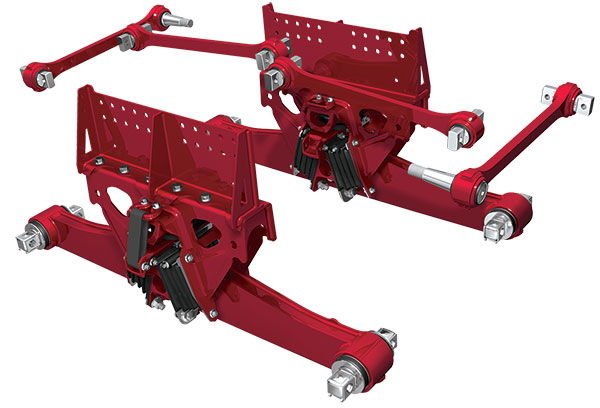

Suspension geometry and spring type are the two biggest influences on driver comfort and equipment protection, points out Mark Molitor, senior product manager for chassis suspensions at Link Mfg. “Two basic categories of suspension geometry are Torque Reactive and Non-Torque Reactive,” he relates. “Both types can provide the vehicle with adequate suspension, but a Non-Torque Reactive suspension will offer the most comfort for a driver and the highest level of equipment protection.

“A Torque Reactive suspension will have a vertical reaction during braking and acceleration events,” Molitor continues. “For example, if a vehicle is equipped with a Torque Reactive front suspension, the front of the vehicle will dive down when the brakes are applied and the more aggressive the braking event, the more pronounced the dive/drop experience will be for the driver. If the vehicle has a Torque Reactive rear suspension, the rear will dive down during braking as well but will also raise during acceleration. All this diving and rising will have drivers pitching back and forth in their seats. If your application has a higher percentage of starts and stops and maneuvering, you should stay away from Torque Reactive geometry.”

Types of suspensions

Fleets have their choice of suspension types, from the more popular air ride and leaf spring to the less common walking beam and rubber ride varieties.

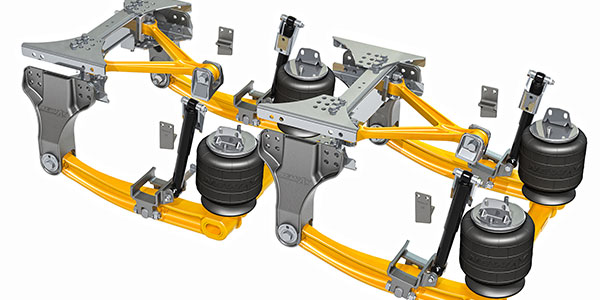

Each of these, Hendrickson’s Krob relates, has features and benefits designed for specific applications. “Air or mechanical rubber suspensions are best suited for driver comfort,” he adds. “An air suspension delivers superior ride quality by using large volume air springs and heavy-duty shock absorbers and a mechanical rubber suspension with solid rubber bolster springs offers a very comfortable ride when the chassis is empty.”

“Vocational fleets and their drivers recognize the benefits of air-ride suspensions and understand that they provide a more comfortable ride versus leaf spring and other mechanical suspensions,” says Bryan Redeker at SAF-Holland. “They also exhibit superior roll stability, especially when carrying high center of gravity loads over uneven terrain and while cornering. In addition, unlike mechanical suspensions that are unable to provide ride comfort when the vehicle is unloaded, air ride suspensions deliver the same level of ride comfort whether or not the vehicle is loaded.”

Across the board, suppliers offer fleets assistance in making the best choice of a vocational suspension for driver comfort. “A manufacturer will identify specific suspensions for fleets to use depending on the type of application and amount of weight the vehicle will be hauling,” Hendrickson’s Krob says.

“After spending time to fully understand a fleet’s specific needs,” Link’s Molitor says, “we have professionals who are very technically equipped to help. We also have an engineering team that is very accessible and eager to talk to fleets.”

Reyco-Granning’s Hinz notes that sales, engineering and manufacturing experts will work to develop a complete suspension solution for customers. “We also follow up with installation reviews, on-site audits, and any other assistance a fleet can use to ensure they have a successful suspension solution.”