What are the latest design trends that fleets can expect to see in wheel end systems? For Divjot Singh, applications engineer at NTN Bearing Corp., the answer is that wheel end technology developments are being driven by the need to reduce turnaround times for service and installation. “That has a big impact on a shop’s throughput,” he says. “The efficient installation and maintenance of wheel end systems allows a shop to achieve high levels of satisfaction and maintain profitability.

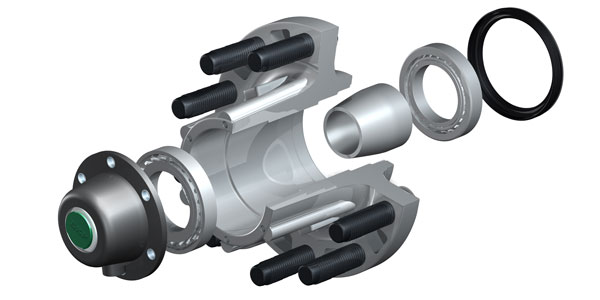

“Typical truck wheel ends utilize a double nut system, consisting of an inner adjusting nut, spindle washer and an outer jam nut,” Singh continues. “But current trends are going toward using a single nut system, which reduces the number of installation steps and also increases accuracy. Future developments are aimed at further easing installation and preventing inaccuracies.”

Bill Hicks, product manager of suspension systems at SAF-Holland, notes that there is a continued push to provide new wheel-end packages or individual components that are part of an overall systems approach. “The aim is to reduce maintenance requirements and increase fleet efficiency while balancing acquisition costs,” he says. “That’s a value equation that can be applied to hub packages and other wheel end components.

“Of particular interest are the current oil bath and semi-fluid grease hub and bearing combinations that are now pushing the envelope for increased service life with limited or no maintenance,” Hicks adds. “This challenges the age-old paradigm of being able to ‘see’ the oil level in an oil bath system to ensure the proper amount of oil in the hub, because grease systems normally do not have a ‘window’ hubcap.”

Ean Dickerhoof, application engineer at the Timken Co., says that as with the majority of trucking components, light weighting and fuel efficiency could become more prevalent for wheel-end systems as OEMs continue to dig for efficiency gains.

“Many of the changes that have been made to wheel end systems have excluded the bearings, but bearing technology has come a long way,” Dickerhoof says. “Using technology that is standard in many other markets, wheel end systems could benefit from more power-dense solutions that could be coupled with fuel efficiency to help create value for fleets.”

Smart wheel ends

Jeff Wittlinger, business unit director of wheels and braking systems at Hendrickson, points to the trend toward using telematics and smart wheel ends to incorporate an element of predictive maintenance. “We understand the value and benefit that component monitoring can bring, “ he says. “As part of our development initiatives, we are striving to create sensor hardware that interfaces flawlessly with data collection software to ensure that information is processed and disseminated in a meaningful, usable way.

“In addition to understanding system integration, we have invested significant time and effort in tackling concerns related to the durability of the physical sensor itself, battery life, exposure to the elements and other road inputs, and transmission capability,” Wittlinger adds.

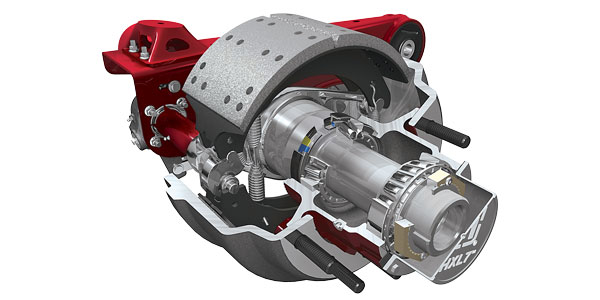

“We are currently developing products that will decrease maintenance costs and maximize uptime,” says Beto Dantas, vice president of marketing, innovation and strategy at ConMet. “One example is the PreSet Plus SmartHub. The in-wheel health monitoring device contains embedded sensors that monitor and transmit data about critical wheel end indicators, including hub temperature, vibration, speed and miles traveled.”

Expected service life

Fleets have an increasing amount of options when selecting wheel end systems. Scott Simmonds, vice president of heavy-duty sales at SKF

Vehicle Service Market, North America, says wheel ends should be specified to last for the equipment’s expected service life,

“Fleets should also consider their application and operating environment,” Simmonds advises. “A fleet may use a trailer for 10 years, but limited control over the use of the equipment may necessitate replacement of seals and adjustments to the wheel ends every three years to minimize downtime.”

When it’s time to replace a failed part, always consider choosing a premium OEM part, advises NTN’s Singh. “The quality of raw materials and manufacturing processes greatly differ between OE quality product and economy products,” he says. “Additionally, it is recommended that when replacing bearings, you should always replace matching bearing sets rather than individual bearings and races.”

“Every fleet manager is looking for the right balance between performance and reduced maintenance and the selection of wheel-end components can have a significant impact on these attributes,” says SAF-Holland’s Hicks. “Typical wheel-end considerations are centered on braking, hub, bearing and lubrication packages, and tire and wheel combinations. There is no one perfect answer, so each fleet will have to consider the pros and cons for each choice as the market continues to push the boundaries of cost versus performance.”

Maintenance considerations

Wheel end systems suppliers cite several maintenance considerations that fleets will need to keep an eye out for. NTN’s Singh says that proper bearing adjustment is a key factor in reducing premature failure in a wheel end. He also advises that you ensure proper lubrication of bearings to prevent overheating and failure. Additionally, it is not recommended to mix and match different greases and oils as they may not be compatible, and you should always use proper tools to install races.

“From a bearing supplier’s viewpoint, achieving the desired bearing setting is key for the entire system,” Timken’s Dickerhoof says. “Too much preload in the system and the bearings could overheat; too much end play in the system causes issues for both bearing and seal life. Appropriate settings can be achieved using preset technology, which uses statistical controls to achieve a desired setting range specific to each wheel end.”

Dickerhoof also relates that the majority of damage to wheel bearings is caused by oil leakage and debris entering through seals, or from degradation of the oil or grease. Therefore, routine checks should be done to assure lubricant and seals are in good condition. In addition, when performing maintenance on wheel ends, knowing the material of the hub (ferrous or aluminum) is critical, as each presents different challenges when replacing bearings and seals without damaging that the hub.

The Hendrickson Trailer Preventative Maintenance Guide, notes Hendrickson’s Wittlinger, recommends visual checks for lubricant leaks and hubcap integrity. The guide also details periodic physical checks for smooth and quiet rotation of the wheel ends without removing the hubcap.

SKF’s Simmonds says that when it comes to wheel end systems, preventive maintenance is often most economical option compared to expensive, non-scheduled service or road calls.