As someone who hasn’t lived under a rock for the past 30 years, it’s fair to speculate you’re familiar with Salt-N-Pepa’s 1987 mega-hit “Push It.” And as a fleet manager, I’ll venture that whenever you hear it, there’s one component you can’t get off your mind for the rest of the day: pusher axles (if that’s not the case, it is now).

Most commonly found in vocational applications, especially on dump trucks, refuse trucks and mixers, pusher axles are in the same family as tag axles when it comes to 6×2 configurations, where only one of the two rear axles receives power (as opposed to 6×4, where both of a tractor’s rear axles are drive axles).

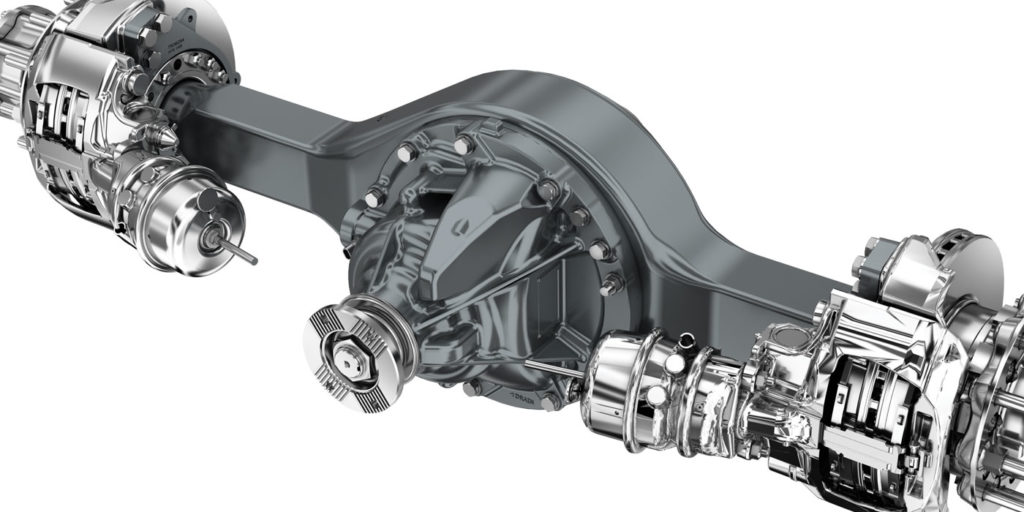

Both pusher and tag axles are non-powered and can be liftable or stationary axles. The goal for both is to help the truck achieve maximum productivity by increasing payload and distributing weight, says Steve Mastroianni, senior manager of product planning for Dana.

“Whereas a tag axle is located behind the drive axles to take some of the weight off the rear drive axles when the vehicle is fully loaded, a pusher axle is positioned in front of the drive axles, adding stability to the chassis during cornering,” Mastroianni says. “The decision to spec either configuration is generally based on load balancing of the vehicle. For handling and weight balance during transport, one or more pusher axles to support the load may be required. Even while dumping a load, the weight is transferred to the rear-most axle, offering the necessary additional support at the rear of the vehicle.”

Do you need a push?

When deciding whether to spec a pusher axle for your truck, first thing’s first: Always consult with the vehicle manufacturer to ensure you’re selecting the proper axle type for your application.

Beyond this, there are several considerations in deciding whether to include a pusher or tag axle in a truck. Some of these considerations for a dump truck, for example, according to RaNae Isaak, powertrain and TCO consultancy leader at Cummins Inc., include:

- federal regulation,

- the state laws including bridge and frost that may impact operation,

- the time spent off-road,

- the duty cycle of the vehicle,

- the weight of the commodity,

- the potential efficiency gained,

- and the maneuverability expected.

“Framing these considerations with expected lifecycle in mind will help fleets reliably plan for overall asset utilization,” she says.

Fleets who find pusher axles are right for their trucks’ application often find the benefits can go beyond added payload, Isaak adds.

“As a fleet manager, you might find a better distribution of weight, which can impact the service of the overall vehicle. You may find improved efficiency when heavy (lift axles down) and then when empty (lift axles up), depending on the frequency and operation in which you use them,” Isaak says. “Depending on your operation and business model, you might find additional opportunities to haul different commodities given the dynamic way you spread the vehicle weight.”

Dana’s Mastroianni adds spec’ing a pusher or liftable axle can include a potential for increased performance by the other axles, resulting in less wear and tear on the vehicle’s tires and ancillary components. Additionally, he says, the vehicle should experience improved stopping distance due to the added brakes on the pusher axle.

Maintaining a pusher axle is similar to maintaining the other axles on the vehicle with the added inspection requirements associated with the additional lift air suspension, Mastroianni says, but pushers can show other maintenance benefits as well.

“Theoretically speaking, a liftable pusher or tag axle should experience increased longevity due to the fact that it’s seeing only half the duty cycle of the other axles on the vehicle since it’s lifted half the time,” Mastroianni says. “Additionally, long life features, such as those provided by Dana on various steerable pusher axles – low maintenance king pin; dual draw keys for durability and reduced tire wear; and one-piece, lightweight forged knuckle for lower weight and reduced parts complexity – can reduce overall service requirements and extend time on the road.”

Cummins’s Isaak adds the main consideration regarding maintenance intervals for Cummins engines is the duty cycle of the vehicle, and the company has a different maintenance schedule for vocational applications. For vocational customers, the X12 provides an oil drain interval of 1,500 hours, 18 months or 40,000 miles, whichever comes first; whereas the X15 has 500 hours, 12 months or 20,000 miles for an oil drain interval.

“Serviceability may be affected by the engine location compared to axle placement, but there is not a unique difference in intervals based on the specific axle choice,” she says.

Of course, that ability to carry more payload often comes with some potential trade-offs as well. For example, says Tony Sablar, Peterbilt vocational marketing manager, these axles add complexity to the vehicle, take up more frame space and may negatively impact maneuverability.

“A pusher or tag axle may negatively impact maneuverability due to the scrubbing effect of the additional tires,” Sablar says. “Steerable pusher axles will help limit the amount of tire scrub, but it will still exist. Lifting the pusher axle may be allowed in slow speed applications. In these cases, the steer and drive axle manufacturers have published ‘creep’ or ‘job-site’ ratings that allow a truck to load the axle over its nominal rating at low speeds.”

He adds, “Some vocational body types and applications will not work with a typical tag axle due to its location.”

Lifting the limits

A truck’s turn radius is one of many factors affected by adding a pusher axle. In the case of a dump truck, for example, spec’ing a pusher axle over a tag axle could result in a less flexible turn radius.

“However,” says Cummins’s Isaak, “depending on the maneuverability requirements within the customer’s route, this might not be an issue. With the development of lift-capable pusher axles, the turn radius and maneuverability can be improved, as long as weight limitations are not limiting the ability to lift the axle.”

Mastroianni says Dana works with various niche specialty vehicle builders that integrate Spicer steer axles and components as part of their liftable, steerable axle solutions, in order to provide improved turn angles and optimal performance.

“Dump trucks spend most of their time at job sites or driving on urban roads between job sites, where tight turns and cornering can be routine,” he says. “In this case, a steerable, liftable pusher axle that aids in maneuverability and allows the axle to remain in the lowered position as needed would maximize productivity.”

Are pusher axles a good fit for over-the-road use? Click here to find out.