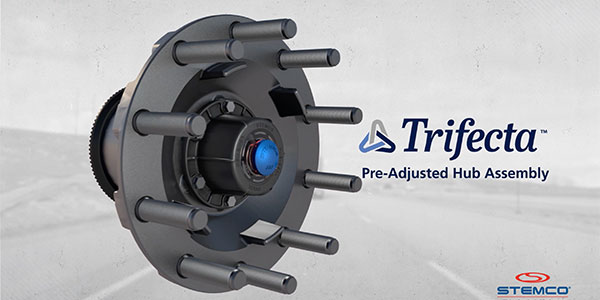

Stemco, an EnPro Industries company and manufacturer of heavy-duty components and solutions for commercial vehicles, introduced the Trifecta pre-adjusted hub assembly during the 2018 Technology and Maintenance Council Annual Meeting and Transportation Technology Exhibit taking place this week in Atlanta. The new wheel end system was developed in partnership with Webb Wheel Products.

The Stemco Trifecta pre-adjusted hub assembly features the Discover XR (denoting extreme runtime) wheel seal with GlideLock technology, the company explained. The seal glides on and is self-locking, reducing installation force by 50%, with no pre-lube required. The combination of the Discover XR wheel seal, Webb Wheel’s hub and the Defender composite hub cap provides the improved contamination and corrosion resistance. The Trifecta assembly also features Stemco’s Zip-Torq axle spindle nut. There are no additional clips, keepers, snap rings or screws to install. The self-ratcheting locking feature prevents inadvertent back-offs.

Click here to read all the news announced at TMC 2018.

Additionally, installation of the new hub assembly requires no bearing adjustment, ensuring the hub is installed correctly, quickly and easily. STEMCO manufactured components ensure simpler, faster wheel end maintenance. The Trifecta offers a five-year/500,000-mile warranty.