The driver shortage is not going away anytime soon. The question is: What are you doing about it?

No, you can’t blink your eyes and magically make 10,000 drivers appear out of nowhere, but there are equipment decisions you can make to ensure your fleet feels the effects of the driver shortage less than your competitors do. That means spec’ing equipment that can recruit new drivers and keep existing ones in their seats longer. These solutions don’t come without cost, but the money you can save by keeping the same driver in the fleet is significant. It’s all about equipment that will keep them in your trucks.

Equipment that comes to mind when you think of driver retention probably includes luxury seats, satellite TV and high-end “reward truck” cabs. But one that may not immediately spring to mind is the suspension.

It makes sense: The suspension plays a major role in the truck’s ride quality. When your drivers are spending eight, 10 or 12 hours a day in your cabs, an improved ride can add up, reducing the pain and strain that are inherent parts of prolonged driving, and helping the drivers feel better when they exit the cab at the end of a long day.

Air ride suspensions provide an improved ride for drivers,

As the air is able to adjust to protect the driver from the effects of the road.

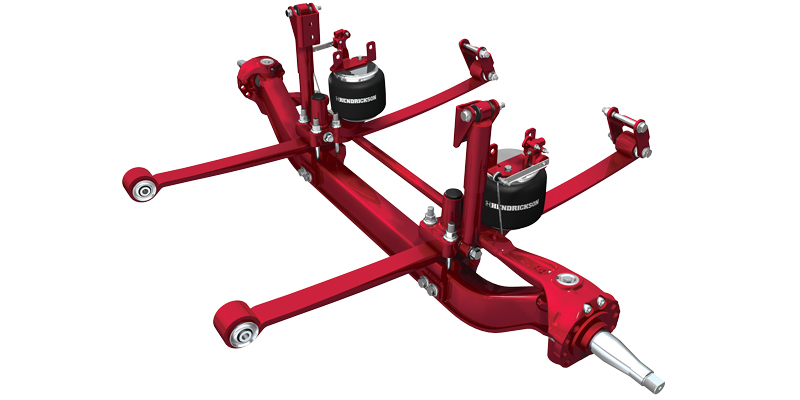

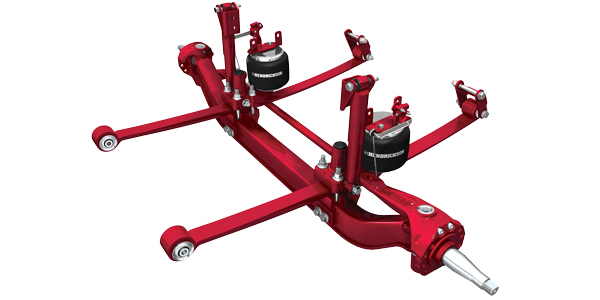

“While we can agree that a suspension’s primary function is not for driver retention,” begins Sean Whitfield, director of marketing with Hendrickson Truck Commercial Vehicle Systems, “front suspension design plays a significant role in overall driver comfort. An integrated front suspension and steer axle system can leverage the latest technologies in both steering geometry and suspension kinematics for better handling and comfort. We have received a lot of valuable driver feedback on our integrated suspension systems. Most of their experiences describe a reduction in cab noise/rattling as well as an overall ease in steering effort.”

The main reason that suspensions have been elevated into the realm of driver comfort equipment is thanks to air ride technology. Air ride suspensions are made up of a system of airlines, air-spring bags and valves, as opposed to springs. Because of this makeup, they provide an improved ride for drivers, as the air is able to adjust to protect the driver from feeling the effects of the road.

According to those interviewed, this has led to an improved market for air ride suspensions as fleets become more driver-focused.

“The growth of air suspensions in the market over the years is largely due to their ability to reduce shock and vibrations transmitted to the trailer from the wheels and road,” says Don Hester, senior program manager for suspensions with Hendrickson. “As driver and technician retention continue to be a problem, providing a better ride and reducing maintenance will become the key in modern suspension designs.”

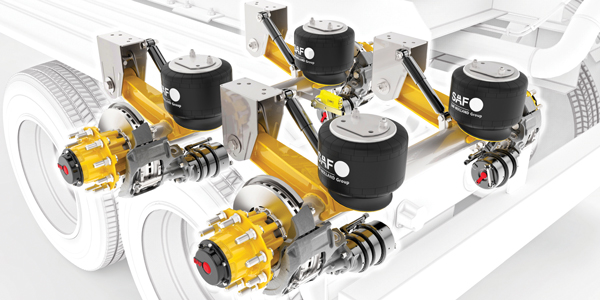

“Ride quality is very important for driver comfort and retention,” says Bryan Redeker, power vehicle suspension product manager with SAF-Holland. “Poor ride quality can lead to discomfort and sometimes sickness for the driver. Given the amount of time a driver spends in the vehicle, ride quality is critical to keeping the driver comfortable and enjoying their time behind the wheel.

Bill Hicks, trailer suspension and axle product manager with SAF-Holland, argues that suspensions should especially be thought of as driver retention equipment for powered vehicles where the driver is the “cargo,” if you will.

“Given the amount of time a driver spends in their vehicle, ride quality is critical to keeping the driver comfortable and enjoying their time behind the wheel.”

Bryan Redeker, SAF-Holland

“With the large penetration of air ride suspensions on the drive axles for most typical North American tractors, this has become almost an expected requirement for drivers, in addition to air-cab suspension and air seats,” he goes on. “The drive axle air ride suspension has the added benefit of reducing cargo damage impacts to the lead part of the trailer through the fifth wheel/king pin arrangement.”

He explains that the SAF CBX air ride suspension series incorporates a multi-function pivot bushing, which provides superior ride quality and roll stability:

“The bushing easily compresses vertically and absorbs energy from road inputs, resulting in improved ride quality with less stress on the trailer frame and suspension components. It’s a small, simple, long life component that impacts driver comfort.”

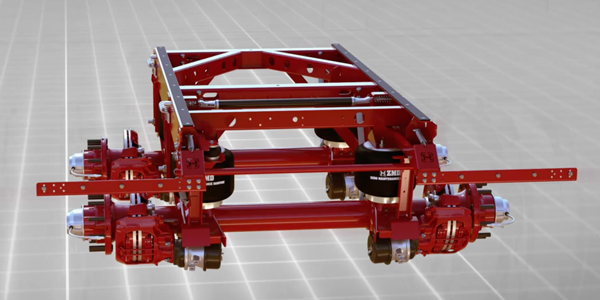

All positions of the suspension, including the trailer suspension as well as the drive axle position and air cab suspensions (more on those on pg. 60), can benefit drivers with air ride technology.

The trailer suspension does not have as direct an impact on the driver’s experience as the drive axle or cab suspension, but an air ride suspension that is designed to adjust to whether the truck is loaded, partially loaded or unloaded will have a positive impact on the ride performance of the entire tractor/trailer—and it’s an adjustment a spring suspension cannot make.

One particular example of a new trailer suspension technology with benefits for drivers comes from Hendrickson’s recently introduced ZMD air spring, which comes standard on Hendrickson’s Ultraa-K suspension and is an option on certain Vantraax and Intraax systems.

Among ZMD’s benefits, Hendrickson reports, is ride quality improvement. ZMD replaces the shock absorbers in the suspension, the primary purpose of which is to cut down on maintenance needs, but which also results in a smoother, less jarring ride for the driver. Hendrickson reports hearing from drivers that ride performance is much improved with ZMD compared to previous air ride technology.

“What we didn’t anticipate was the reaction we received from drivers,” Hendrickson’s Hester says. “Upon launching the product, we nearly immediately got comments from drivers that the ZMD system provided significantly better ride over existing suspension designs. Further field trials corroborated the driver experience.”

Related topics: What’s next for suspensions and A look at air cab inspections.