Enacted by Congress in 1975 to limit the weight-to-length ratio of a vehicle crossing a bridge and to provide a consistent way to determine the maximum allowable weight that any set of axles on a vehicle may carry on the Interstate highway system, the Bridge Formula has had an impact on axle and suspension design ever since.

Federal law states that two or more consecutive axles may not exceed the weight computed by the Bridge Formula even though single axles, tandem axles and gross vehicle weights are within legal limits. As a result, the axle group that includes the entire truck— sometimes called the “outer bridge” group—must comply with the Bridge Formula. Interior combinations of axles such as the “tractor bridge” and “trailer bridge” must also comply with weights computed by the Bridge Formula.

Until 1982, the Federal Bridge Formula only set upper Interstate System weight limits. A few states retained significantly lower weight limits, which eventually became barriers to long-distance truck traffic. In 1982, the Federal law was amended to make Interstate System weight limits, including Bridge Formula limits, both the maximum and the minimum weights that states must allow on the Interstate System. Today, Interstate System weight limits in some states may be higher than these figures due to “grandfather” rights.

“Bridge laws still vary by state,” says Karl Mayer, director of product line management for North America, axles at Meritor. “In general, the regulations call for no more than 20,000 lbs. on an individual axle and 34,000 lbs. on a tandem, but every state has its own regulations regarding weight distribution.”

Design factor

While bridge laws are always a design factor for axles and suspensions, Mayer notes, manufacturers must always work with OEMs to make sure the components and systems are correctly integrated into vehicle designs. “For example,” he adds, “when an OEM has a new suspension, we have to test it with our axles to make sure it will meet the standards for integration and durability.”

While bridge laws are always a design factor for axles and suspensions, Mayer notes, manufacturers must always work with OEMs to make sure the components and systems are correctly integrated into vehicle designs. “For example,” he adds, “when an OEM has a new suspension, we have to test it with our axles to make sure it will meet the standards for integration and durability.”

William Hicks, director, product planning and market development, axles and suspensions—trailer systems at SAF-HOLLAND, points out that bridge laws don’t differentiate by suspension design or type but rather by axle capacity, spacing or grouping. “Working directly with trailer OEMs, suspension system providers will determine which product is best suited to the trailer configuration and type of application that is being targeted,” he says. “Also, to meet unique requirements, state and provincial laws are considered when designing the trailer and suspension system. From a suspension design standpoint, the main considerations are the capacity and axle spacing required.

“Axle capacities determined by the Bridge Formula have been industry standards for years; so the challenging factor is the spacing,” Hicks continues, “and some suspension designs are more flexible with regards to axle spacing. Typically, North American applications are closed spaced sliding tandems for dry freight van and reefer applications of less than 50 in. from the lead axle center to the second axle. However, widespread or 121-in. axle spacing on a tandem trailer does lead to potential ‘bridging’ situations, which have to be taken into account by the suspension system provider.”

Lowering costs

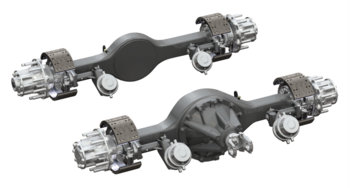

Among the newest axle/suspension designs are 6×2 configurations, which provide fleets hauling diminishing and varying loads with the benefits of tandem axle capability only when it is needed, saving fuel, tires and brakes, and lowering costs for wheel end maintenance.

“In addition to providing the fuel and weight efficiencies,” says Paula Ngo, marketing coordinator at Hendrickson Truck Commercial Vehicle Systems, “our OPTIMAAX 6×2 system for on-highway tractor applications offers versatility through its liftable axle. The integrated lift axle, suspension and controls are installed in the pusher position, allowing the tractor to operate in both 6×2 and 4×2 configurations. The lifted axle position also provides increased traction by increasing drive axle load, which offers an advantage versus traditional 6×2 tag systems when backing under trailers in soft soil or wet conditions.”

In addition to a 2.5 to 3% fuel economy savings possible with 6×2 systems, Ngo notes that OPTIMAAX can achieve an additional two percent in fuel savings in its lifted position, yielding up to five percent total fuel economy improvement, and a 350-lb. weight savings over 6×4 configurations. In addition, driver intervention and training for axle lowering and lifting is not necessary due to the system’s fully automated load-sensing controls.

Growing numbers

The Spicer EconoTrek 6×2 tandem axles from Dana Holding Corp. reduces vehicle weight by up to 400 lbs. when compared with a traditional 40,000-lb. 6×4 tandem axle arrangement, the company notes, and it offers increased fuel economy of two to three percent in heavy-duty linehaul tractors. “Growing numbers of North American fleets are recognizing the gains in fuel efficiency they can achieve by spec’ing 6×2 axles for select applications,” says Pat D’Eramo, president of Dana Commercial Vehicle Driveline Technologies.

Meritor’s FUELite Tandem is the first member of a 6×2 configuration axle family called the SoloDrive Series. Based on the manufacturer’s 160 series drive axle, FUELite Tandem delivers nearly 400 lbs. in weight savings versus a standard 6×4 and provides an approximately 2% fuel efficiency increase, the company states.

“What we’ve done with FUELite is to design a 6×2 solution that meets OEM existing architecture requirements,” says Karl Mayer. “There is no new re-engineering of chassis integration points because the tag axle has upper torque rod brackets that bolt to existing points used in 6×4 configurations. The differences are found in the 6×2 system that has electronic controls to transfer weight onto the drive axle and a thicker axle housing to accommodate that load shift.”

The SAF CBX40 with Auto-Posilift is a 6×2 system developed for varying load fleet operations such as multi-stop beverage distribution, LTL, food service and any fleet that routinely backhaul empty. The combination of the CBX Posilift with an electronic control unit and air valve system creates a lift axle with automatic operation that complies with DOT regulations, the company notes. The system’s ECU is pre-programmed to sense the load weight, and as the trailer load diminishes or increases, it automatically raises or lowers the front axle of the tandem slider suspension without any need for driver interaction.

Market pressures

“Suspension system providers are continuously evaluating new concepts and materials to improve overall reliability and durability while balancing weight and cost,” says SAF-HOLLAND’s William Hicks. “Continued market pressures for increased fuel efficiency and reduced trailer weight have opened up greater opportunities to suspension systems providers to demonstrate the value of upgraded componentry and provide greater overall value or reduced life cycle costs.”

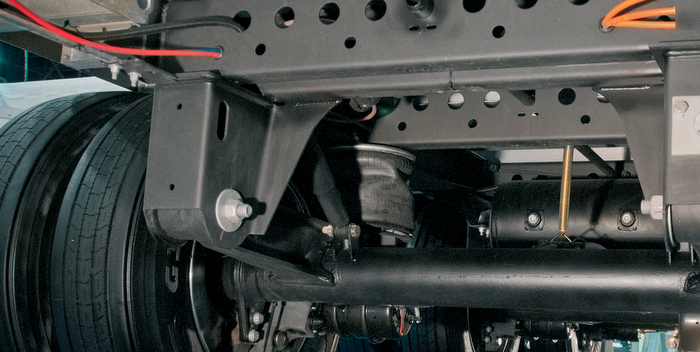

ContiTech air spring system

ContiTech air spring system

ContiTech sleeve type air springs are used in driver seats and truck cabin suspensions worldwide and are designed to reduce road vibrations and provide a more comfortable ride for the driver. The driver is able to adjust the seat height by changing the air pressure inside the air spring to achieve a more comfortable ride position and maintaining the same ride height while driving. ContiTech sleeve type air springs low natural frequency helps in providing a more comfortable ride and therefore, a more productive driver. ContiTech manufactures many different types of sleeve type air springs that can be used for most seat and cabin designs. Using ContiTech air springs in the cab and the driver seat suspension will provide a more comfortable ride, according to the company.