The benefits of moving your fleet to a condition-based maintenance program

Controlling maintenance costs, hitting that perfect level where costs are under control as much as possible, uptime is maximized and unplanned events are limited: these are the things that keep fleet managers up at night, and the things that drive many of their spec’ing choices. But it’s also worth thinking about your trucks’ maintenance intervals.

Operating lean may not work in the future for shop administration

For years, those of us in this profession have had the idea beaten to death that we shouldn’t spend money, don’t have too many mechanics, don’t overstock inventory. We even have gone through a phase that maybe we should have consignment parts or even outsource the parts room to a third party. We were brought

Vipar Heavy Duty highlights fleet service program, order management system

Vipar Heavy Duty highlights its fleet program, which the company says offers fleets of all sizes and vocational areas access to its brands and technology solutions to increase efficiency and enhance maintenance practices, supported by its network of parts and service locations across the U.S., Canada, Puerto Rico and Mexico. “Vipar Heavy Duty works with

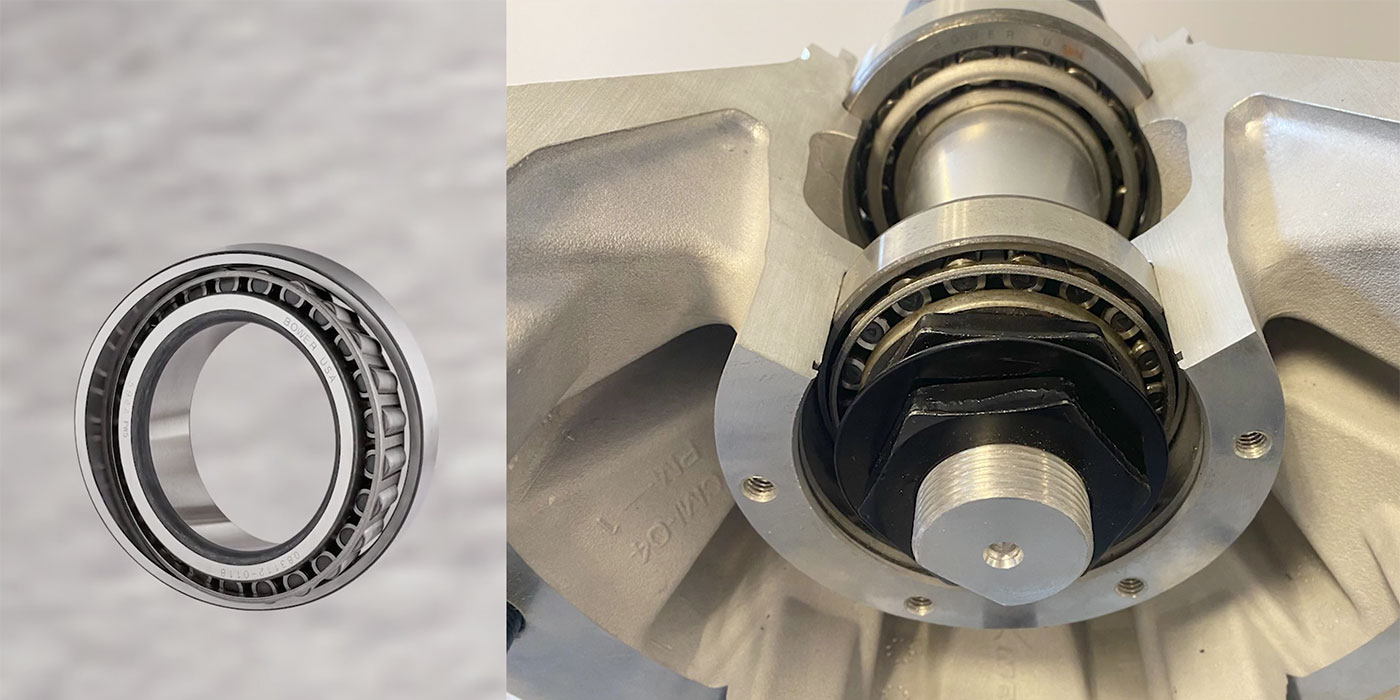

The 8 most common wheel bearing maintenance issues

Wheel bearings may not be the first item you think of when making your fleet’s maintenance checklist. There are bigger components—the engine, the tires, the safety system—that, just by their nature, demand more of your attention. But that does not mean that wheel bearings can be swept under the rug, as failures can lead to

Five electric truck questions with Manhattan Beer Distributors

If you’ve ever been in New York City and purchased a beer from a bar, restaurant or similar establishment, there is a sizable chance that it got there by way of Manhattan Beer Distributors. The New York fleet services all of metro New York City with its 400 trucks, delivering 45 million cases of beer

Wheel hub locking nut tips for conventional, spacer setups

In a typical HD wheel hub assembly, the locking nut is used to hold assembly together and also set the bearing end play (for conventional setups). There are many types of lock nuts in use. The most common ones include:• Conventional Dowel Type (Double Nut)• Single nut with separate keeper (Ex: Stemco’s Protorq)• Integrated design

What you need to know about pre-adjusted wheel bearing

For the Heavy Duty truck market, there is an option to use pre-adjusted wheel bearing sets with spacers or conventional wheel bearing sets. Pre-Adjusted sets are typically used with a spacer setup. We get the question “Can a technician use a conventional bearing set with a spacer in place of a pre-adjusted set”. Short answer

Bi-directional testing: How it can speed up truck shop operations

What is the problem? It’s the most basic and, oftentimes, most perplexing question in truck repair. Trucks are complex machines driven by computer controls. Fault codes do their best to point technicians in the right direction, but being able to quickly to diagnose the root cause of the service problem is paramount. Enter bi-directional testing.

Carrier Transicold introduces BluEdge service platform

Carrier Transicold truck and trailer customers now have access to the BluEdge service platform, which is now fully available from Carrier Transicold’s dealer network across the U.S. and Canada. BluEdge offers three tiers of service, adding augmented capabilities when integrated with Carrier Transicold’s eSolutions monitoring system. Tier offerings include: Core – Supplements the original equipment

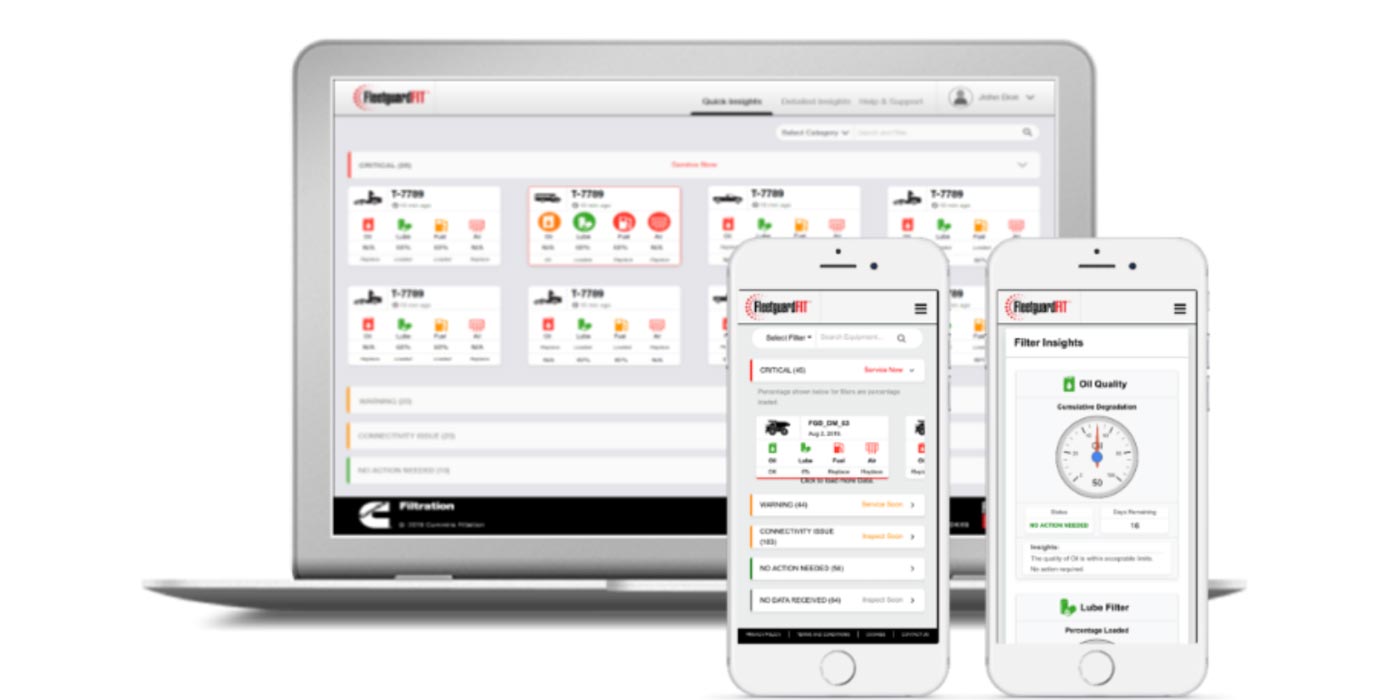

Donaldson updates Filter Minder Connect, previews additional capabilities to come

In a recent press event, Donaldson outlined new and upcoming updates to Filter Minder Connect, its solution for monitoring fuel filters and engine oil condition on heavy-duty truck engines. Among the updates Donaldson outlined are: Engine Oil Monitoring: This contains two components, one of which is a remaining useful life model that will help users

How truck lease structure impacts maintenance, repair costs

The broader economy has rebounded quite well from the severe market turbulence of 2020—and seven countries, including the U.S. and China, have already reached their per capita GDPs return to pre-pandemic standing, according to the latest report from the Organization for Economic Co-operation and Development (OECD). According to the group, global economic output will rise

You need to update your truck shop software

Seriously, if you’re not sure if your shop software is updated, you should probably stop what you’re doing and check right now. If your truck shop scan tools and service software solutions don’t have the latest software build, update them now. It’s important that your shop’s diagnostic and scan tools operate the latest version in