Volvo Trucks N.A. pres. talks electric truck service, the Daimler/Volvo JV

You got the high-level view of Volvo’s decarbonization efforts, both diesel and electric, in our exclusive executive interview story with Peter Voorhoeve, president of Volvo Trucks North America. But Peter and I spent much of our time together in the weeds, talking about the nitty-gritty details of early electric truck adopters, the EV service and

Bosch ESI[truck] 2021/4 software update offers a truck-ton of new tests and codes

Bosch has announced the 2021/4 software update for the 3824A ESI[truck] Heavy Duty Diagnostic Solution. Thousands of new tests and codes have been added to help technicians provide the most up-to-date service on hundreds of commercial vehicles, including includes new makes and models that can be serviced, such as Navistar MaxxForce engines, Mack TCM Transmission,

What does OEM approval mean for transmission fluids?

By Darryl Purificati, Sr. Technical Advisor, OEM/Automotive at HollyFrontier Lubricants & Specialties, which includes the Petro-Canada Lubricants brand Transmission fluids are some of the most complex driveline fluids and are formulated differently depending on the transmission they will be used in. They perform a range of functions such as lubrication, heat dissipation, wear protection and

Getting heavy-duty, medium-duty trucks to talk the same service language

When a truck service location is faced with both heavy- and medium-duty vehicles all sporting different name plates, there’s often a communication breakdown. Technicians interface with different trucks in different ways, they have to use various methods of pulling the needed service information off said trucks, and jumping back and forth between heavy-duty and medium-duty

Peterbilt deploys augmented reality tool for technicians

Peterbilt Motors Co. will have deployed 200 of its patented ARTech augmented reality tools to dealer locations by March 31, 2022. A proprietary software designed to innovate dealer service and improve customer uptime, ARTech utilizes three-dimensional and augmented reality views of chassis-specific Peterbilt trucks, along with existing service systems like PACCAR Solutions Service Management to

Tires for Vehicles with Extended Life Cycles

Due to a shortage of new commercial vehicles brought on by the pandemic, fleet managers are extending the life cycles of their existing vehicles. In a July Autosphere article Stretched Utilization on Fleet Lifecycles, Chris Hill, wrote, “Fleet managers are responding to the lack of new vehicles by extending the lives of those they currently

How proper truck battery maintenance can help avoid winter catastrophe

Among the many truck components that fall victim to the harsh winter, one of the most prominent is the battery. No-starts, freezing: it’s hardly an exaggeration to say that a dead battery is a death sentence for that truck’s uptime and productivity. Contrary to what many believe, the time to avoid winter’s effects on the

Electrical system maintenance to improve aftertreatment performance

Running a regen is an easy out to deal with aftertreatment issues, but even if it fixes the problem in the short term, you’re sure to see that same truck back in the shop with the same set of aftertreatment-related faults. You need to get to the root of the aftertreatment system’s problem, and the

Replacing heavy-duty truck wheel bearings: Steel, aluminum hubs make a difference

When it comes to replacing heavy duty wheel bearings, it’s important to know the differences between steel and aluminum hubs. So let’s chart the differences. Starting with steel hubs, you’ll notice that it’s a more forgiving material and you don’t need to be as careful compared to working with aluminum. It’s typically also easier to

Standard-temp vs. high-temp clutch pilot bearings: What’s the difference?

When replacing a heavy-duty clutch pilot bearing, there are a few options to consider. You should always follow the OEM recommendations as they will require either standard- or high-temperature bearing, and that difference between the two is extremely important. While clutch pilot bearings are often thought of as a relatively simple deep groove ball bearing,

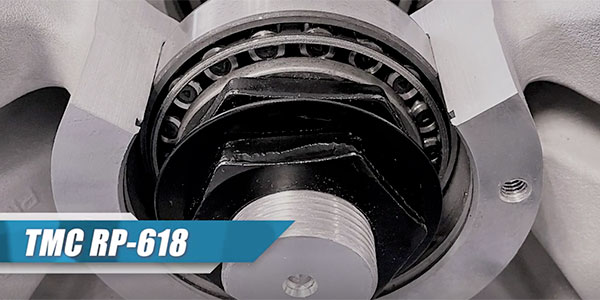

Tech tip: Proper truck wheel bearing adjustment

It’s important to know what the proper bearing adjustment is to reduce premature bearing failure. For optimal bearing life, you want to have an ideal bearing end-play setting between 0.001 inches and 0.005 inches in heavy-duty wheel-end applications. To eliminate the guesswork, the TMC RP618 was designed for heavy duty wheel bearing adjustment and allows

How electric trucks could change service shop operations

Electric trucks are coming and reduced maintenance is potentially coming along with them, but that doesn’t mean that truck service is going to change overnight. There will be differences, but electric trucks offer an opportunity, not a threat, to truck service operations. While there are plenty of conversations to be had about service needs and