How to prevent transmission overheating

Medium- and heavy-duty truck transmissions undergo a lot of stress and abuse throughout their lifetimes. With the elevated loads that the transmissions undergo, an abundant amount of heat is generated due to higher internal friction. If heat generation is left unchecked, it can lead to complete failure of the transmission. With this in mind, Mitchell

The advancements of diesel technology

While significant technology advances were made to the diesel engine over the past century, the most significant advances have been made in the past 20 years. Here’s a look at some of them.

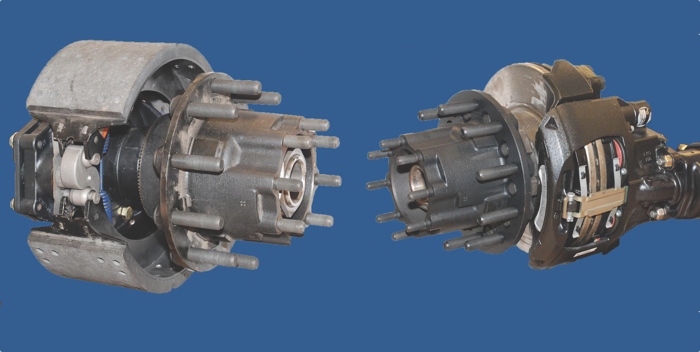

Disc brakes vs. drum brakes

When deciding on specs for a commercial truck, the braking system is one of the most important components to consider. There are several aspects to think about, but one of the first decisions is most likely going to be between disc and drum brakes. Each type has pros and cons that will impact different users

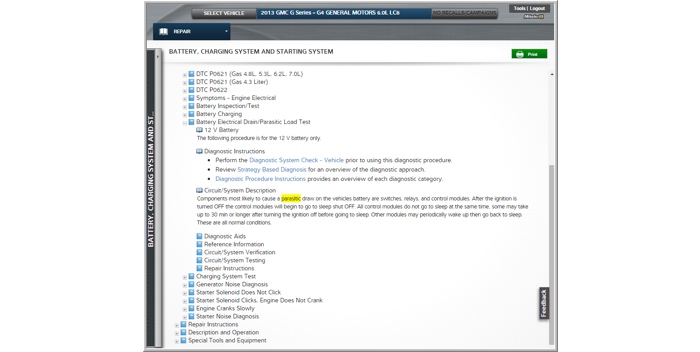

Diagnosing parasitic loads

With increasing electronic controls in modern trucks, parasitic loads are becoming a larger concern for today’s fleets, especially in fleets where vehicles may be parked for long periods of time. With so many electrical circuits in these vehicles, any one of them may be a culprit, making diagnosing a bit like looking for a needle

Mitchell 1 updates interface between RepairConnect and Noregon JPRO software

Mitchell 1 has announced an update to the interface between its RepairConnect diagnostic trouble code troubleshooting tool and Noregon’s JPRO Professional commercial fleet diagnostics software, giving technicians streamlined access to TruckSeries, the latest version of Mitchell 1’s repair information for Class 4-8 trucks. The RepairConnect module in TruckSeries includes all of the diagnostic trouble code

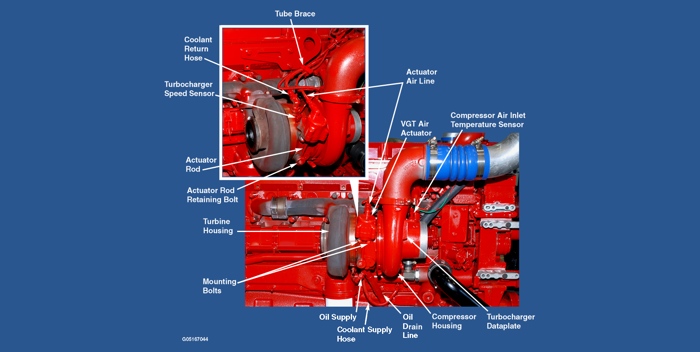

How to increase turbocharger efficiency through proper maintenance

Turbochargers are an important component on today’s commercial vehicle diesel engines and are engineered to provide optimal performance throughout the engine operating range. Keeping the turbocharger and associated systems well maintained can have a big impact on overall vehicle efficiency. Turbochargers use exhaust energy to drive a turbine wheel, which in turn drives a compressor

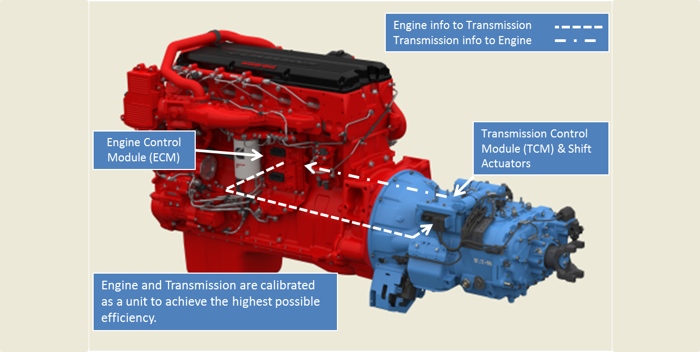

Achieving optimum powertrain performance with proper service procedures

The Environmental Protection Agency (EPA) has established standards to reduce fuel consumption and greenhouse gas (GHG) emissions for the heavy duty trucking industry. These new standards have resulted in manufacturers developing every aspect of a truck’s powertrain to achieve optimum fuel efficiency. Part of this development includes calibrating engines to transmissions to maintain optimum powertrain

Mitchell 1 updates web-based truck repair information software

Mitchell 1 has completed model year 2015 updates to its TruckSeries software suite, covering repair information, labor estimating and diagnostic trouble code procedures for all makes of medium- and heavy-duty trucks. The software is available for Classes 4-8. Mitchell 1 keeps its software current throughout the year with running changes and adds data for the

It’s time to winterize your truck’s electrical systems

Vehicles endure harsh conditions as they work continuously through the changing seasons. Winter can be one of the harshest because of the various challenges it presents with cold temperatures and extreme weather. In particular, excessive water and moisture from rain and snow are very corrosive and can degrade the condition of the vehicle materials. The

Warm weather battery tips

Note: This article was contributed by Andrew Carlson, Mitchell 1 technical editor. As summer transitions to fall, high temperatures persist in many parts of the country that can present some extra challenges for truck maintenance. In particular, your truck’s charging system needs some special attention in hot weather to ensure peak performance. It’s important to make

Timely Tips: Commercial Vehicle Safety Alliance (CVSA) Level I and Level V Inspections

The Commercial Vehicle Safety Alliance (CVSA) is an organization that establishes out-of-service standards for commercial vehicles operating in North America. CVSA level I and Level V inspections can place a vehicle out of service if violations are discovered during the inspection process. Level 1 inspections review driver qualifications/standards as well as critical vehicle areas that

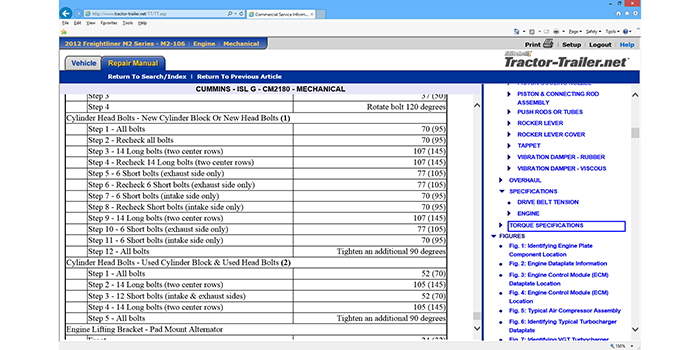

Tightening the focus on torque specs

Today’s complex medium-duty, vocational engines require the same attention to detail when completing a repair.