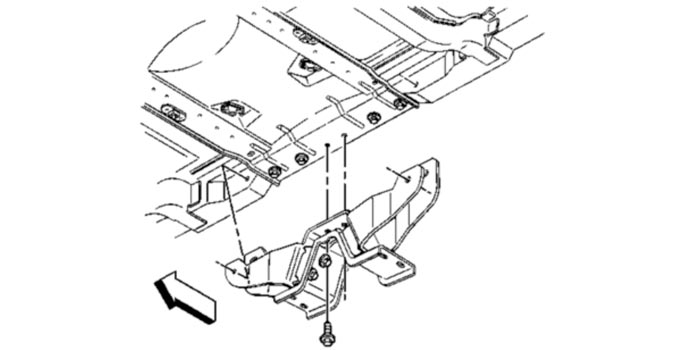

Keeping the tractor-trailer connection healthy

Connections are made all over the vehicles we service. For the most part, those connections are probably taken for granted until there is trouble.

Three inspections to prevent uneven brake wear

Maintenance during the winter months presents unique challenges. Ice, slush, and general muck on the roads take a significant toll on brakes and other exposed components. Any road grit that finds its way into moving parts can result in binding and uneven wear, and there is a greater potential for damage from larger highway debris

Don’t Call the Customer–Text Them!

The truck is torn down in the service bay, awaiting a customer callback to approve an addition to the original estimate. Three other trucks are in line to be serviced. Unfortunately, there is no easy way to get the disassembled truck back together. The frustrated technician is held up from starting on the other jobs.

That tingling sensation: How driver discomfort can reveal areas of the truck in need of maintenance

The driver climbs out of the cab, rubbing a leg when dropping the truck off for regular service. “How’s your day going?” you ask. “Great!” the driver responds, “Except for my leg going to sleep.” “Yeah, I hate it when that happens,” you respond. The conversation goes on as you and the driver discuss the

Mitchell 1 adds text messaging feature to Manager SE Truck Edition

Mitchell 1 has introduced new text messaging features in its Manager SE Truck Edition shop management system for Class 4-8 trucks. The latest release of Manager SE Truck Edition introduces a new MessageCenter option with integrated two-way texting. Shops have the choice of building their own text templates for orders, appointments and revisions, or writing “on-the-fly” text

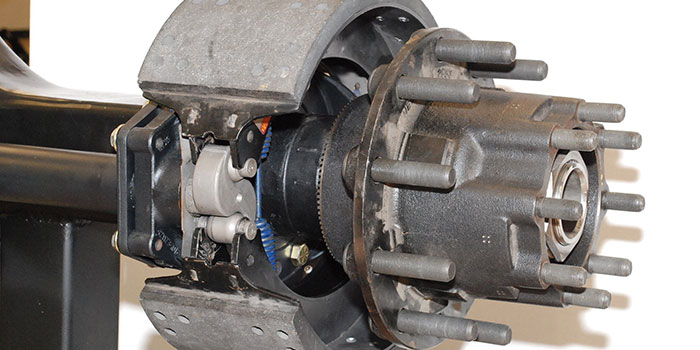

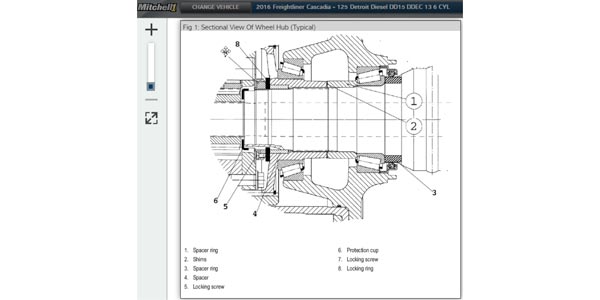

How wide base tires can impact axle maintenance

Chances are, you don’t think too much about axles unless there is a particular problem. Wheels and tires are another matter altogether. For one thing, wheels and tires are visible to everyone who sees the vehicle. They are attention-getters even from people not involved in the industry. Plus, nice wheels make the truck look good,

Engine diagnostics: Don’t forget to ask questions

The truck rolls in with a diagnostic trouble code light on. The chances are good that the first thing a technician will do is grab a scan tool and see what code or codes have set. However, it’s important to also remember the most basic diagnostic step: asking questions. Asking the driver questions about the

Beyond ‘What failed?’—know why it failed

It’s natural for anyone who works on similarly-equipped vehicles to discover patterns in the failure points, particularly with diagnostic trouble codes. The first few that come into the service bay usually mean the tech will need to closely follow the diagnostic steps. At least, that’s what happens in a perfect world. Reality is a much

Three tips for seat belt maintenance

Seat belt laws have been in place long enough that most everyone has become accustomed to buckling up. You get in, reach over, pull the belt across and click it in place. It is most likely such an automatic part of getting ready that the act hardly gets noticed. As a result, seat belts can

Don’t ignore that in-line air filter

When it comes to air filters, most replaceable filters for the engine air intake, or spin-on air filters for the air brake system, are likely to be on a regular maintenance list. But what about in-line air filters for the trailer air system? Some trailer brake systems will have in-line filters designed to screen

Detecting tricky transmission leaks

Have you ever worked on a transmission leak only to discover the fluid was coming from another part of the engine? If so, you’re not alone. Here are some tips for tracking down the true source of those fluid leaks. Transmissions have a way of getting the rap for sloppy neighbors. We all know that

Tips for diagnosing intermittent electrical issues

Diagnosing performance problems is often challenging, especially when the concern doesn’t happen all the time. Intermittent problems tend to be time consuming and frustrating to diagnose. The diagnostic process for such issues sometimes amounts to trying a replacement part stored in the toolbox for just such occasions. That can work, but not always. For instance,