Watch: Heavy-duty truck air disc brake maintenance tips

Over the past several years, adoption of air disc brakes (ADBs) has climbed to 18% to 25% of brakes ordered on trucks, according to brake manufacturers, who anticipate that number reaching 50% within the next decade. One of the major advantages of air disc brakes is the extended service interval for brake friction. However, that

Avoiding coolant-related heavy-duty engine failures

Fifty-three percent—that’s the percentage of catastrophic, premature diesel engine failures directly related to improper cooling system maintenance techniques and habits, according to filter manufacturers. Filtration plays a key role in coolant maintenance. Using the proper coolant filter can prevent scale, leakage and erosion in the cooling system. The filter captures damaging contaminate that may contribute

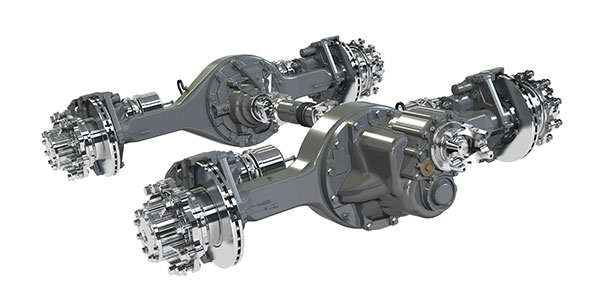

Why heavy-duty gear oil quality matters

Gear oils provide multiple important functions when it comes to the operation of gears and axles. As gear oils flow around axles, they help to cool the critical hardware components by carrying heat away and dissipating it. They also help to keep hardware components and assemblies clean by suspending contaminants, which would otherwise lead to

Watch: Tracking truck warranty information with fleet maintenance software

Improved maintenance processes, inventory management, and repair order generation and reporting are all staples of fleet maintenance software, but there’s one major component that might not immediately spring to mind but can pay dividends: warranty tracking and recovery. Many aftermarket parts come with a warranty ranging anywhere from 90 days to two years. When it

Watch: Detailing heavy-duty truck bearing maintenance, fuel efficiency gains

To squeeze the most fuel savings out of your next truck spec, you might want to extend efficiency gains out to your wheel end through the spec’ing of high-efficiency bearings for that extra fraction of fuel efficiency gain. While a fraction of a percentage might not seem like a lot for one truck, spread it

Inside automated manual transmissions with predictive cruise control

Introduced to the market only a few years ago, automated transmissions equipped with advanced cruise control features are now a staple of OEM offerings. Predictive cruise control systems use GPS data, onboard maps and cruise control to optimize cruising speed based on the topography of a truck’s route. As the truck enters certain types of

Watch: Top truck tire inflation tips

Heavy-loads and high speeds, combined with underinflated tires can make for an on-road catastrophe. The excessive heat being generated by an underinflated tire due to the increased flexing of the tire sidewalls in combination with the longer footprint leads to rubber compounds failing. Air pressure is based on the worst-case load the tire will see

Achieving 10 MPG in the real world

Let’s talk achieving 10 MPG in the real world. The North American Council for Freight Efficiency (NACFE) released an in-depth report on the Run on Less fuel efficiency roadshow, demonstrating high miles per gallon using currently available technology. The reports provides analysis of key data from the three-week event, from which four key conclusions were

Let’s talk FA-4 engine oil benefits, management

With a year of the new American Petroleum Institute CK-4 and FA-4 oil categories under the industry’s belt, it’s a good time to take stock of the FA-4 oil benefits. To date, API has licensed approximately 83 FA-4 oils, which ensure that the newest categories of diesel oil for use in on- and off-highway vehicles

Let’s talk heavy-duty truck VMRS codes

The ATA Technology and Maintenance Council (TMC)’s Vehicle Maintenance Report Standards (VMRS) program was started in 1970 with the goal of developing a standard method of communication for everyone involved in the truck maintenance process, from fleets to repair shops to OEMs. Last year, VMRS Codes Committee determined that VMRS needed more flexibility to describe

Let’s talk spring suspension maintenance

Spring suspension manufacturer maintenance recommendations include periodic checks of fastener torque values and usually include an initial re-torque after break-in. While regular preventative maintenance will keep the majority of spring suspensions rolling productively, there may come a time when a spring needs to be replaced. Typically, a broken spring can be identified during a walk-around

Getting more from your ELD solution

With the ELD implementation date behind us and enforcement just around the corner, you’ve probably seen ELDs at work in your fleet over the past several months. Now that you’re comfortable with the logging capabilities, let’s look at some other advantages. The implementation process likely highlighted that there is a lot of information available. With