Phillips Industries introduces interior corner lights with motion detection for dry vans and reefers

Utility Trailer Manufacturing Co. selected these new lights as their standard interior trailer lights for their refrigerated trailers.

Utility Trailer produces its 200,000th trailer

Utility Trailer Manufacturing Co., the manufacturer of refrigerated trailers and manufacturer of dry freight vans and flatbed trailers has announced its Paragould, Arkansas manufacturing facility has produced its 200,000th trailer, a 4000D-X Composite dry van. Utility’s Paragould, Arkansas plant marked an important production milestone when Target Corp. purchased its 200,000th trailer. Target received the 4000D-X

North Central Utility opens new dealership in St. Cloud, Minnesota

Utility Trailer Manufacturing Co. announced that North Central Utility has opened a new dealership in St. Cloud, Minnesota. The new dealership is 27,000 square feet and offers reefer, dry van and flatbed trailers from Utility. The new facility features seven service bays, one of which is an isolated wreck bay, 5,000 square feet of parts

Utility Tri-State relocates dealership to Oklahoma

Utility Trailer Manufacturing Co. and Tautliner curtainsided trailers have announced that Utility Tri-State, Inc. has relocated its Siloam Springs, Arkansas dealership to West Siloam Springs, Oklahoma. The new dealership is approximately 53,000 sq. ft. It features eight interior service bays, including one service bay outfitted with roof-work scaffolding to help increase speed and safety, as

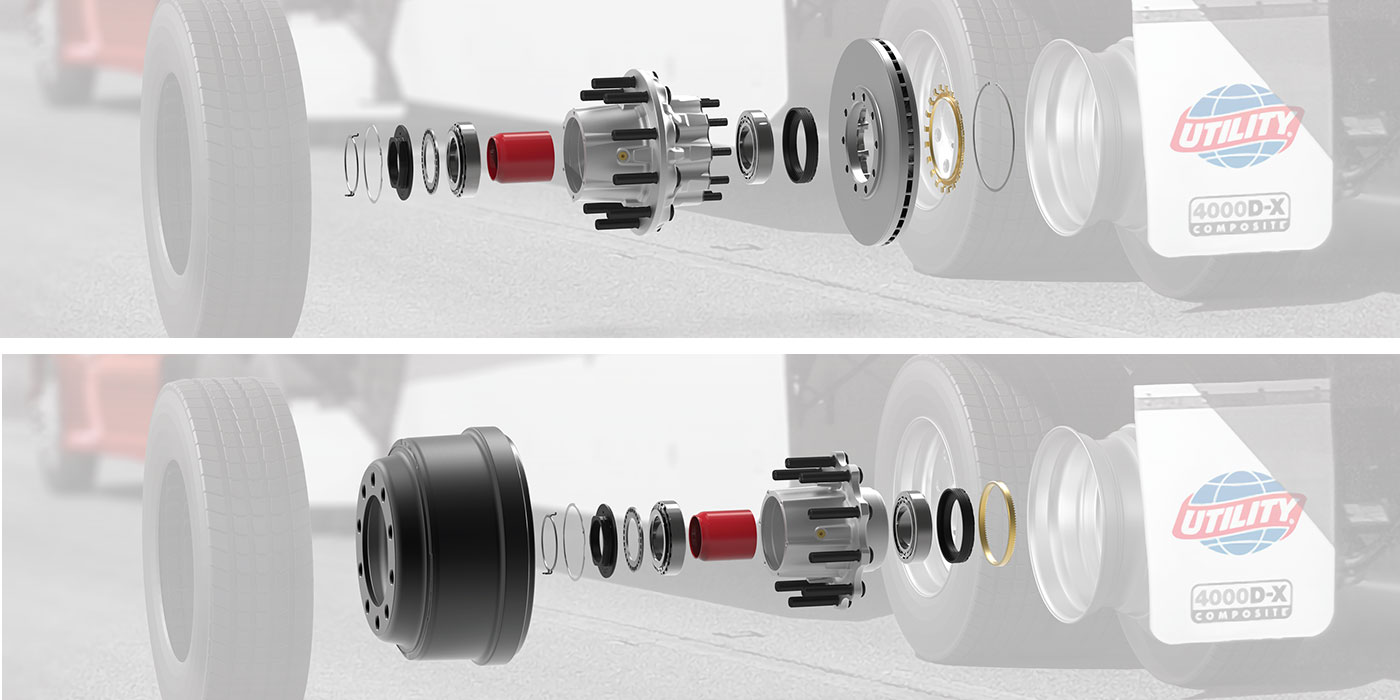

Utility makes ConMet Preset Plus standard on all trailers

Utility Trailer Manufacturing Co. has made ConMet Preset Plus wheel end hubs the standard base specification on all Utility trailer models. The company says ConMet Preset Plus features: an optimized bearing spacer; long-life bearings engineered to withstand demanding operating conditions; an integrated spindle nut; precision machined casting; extended life seals; ABS tone ring; magnetic fill

Utility Trailer implements standard 7-in. rear impact guard on all trailers

Utility Trailer Manufacturing Co.‘s dry vans, refrigerated vans and flatbeds produced after 2002 can now be retrofitted with Utility’s standard 7-in. deep horizontal Interstate Commerce Commission (I.C.C.) bumper. Federal Motor Carrier Safety Administration (FMCSA) recently proposed to include the rear impact guard on the list of items that need to be examined during a commercial

Using technology to stay on top of trailer maintenance

The technology offerings in the trucking industry today are innumerable, so it should come as no surprise that there are several technological methods that can help improve your winter maintenance program. For example, many trailer components can have sensors attached that report data to a main telematics hub, giving you an inside look at the

Hauling refrigerated goods in the winter

If you haul refrigerated products, keeping them cold in the summer is of obvious importance; but in the winter it gets tricky—because there is such a thing as too cold. “For optimal food quality as well as food safety, temperature control of perishable products is always important regardless of whether it’s hot or cold outside,”

Winter-proof: How to keep your trailers in the best possible shape during the harshest season

There’s plenty to like about the winter, but it’s not all skiing and hot chocolate, especially if you’re a fleet manager who has to worry about the damage the harsh season will cause your equipment. Let’s zero in on trailers, which are susceptible to a variety of potential issues when running during the winter. Luckily,

Fleet profile: Decker Truck Line

At Decker Truck Line, driver engagement is an all-encompassing affair.

Fleet Profile: Hardy Brothers is dedicated to professionalism

The emphasis on safety at Hardy Brothers is supported by investing heavily in technology.

Utility Trailer Manufacturing Co. emissions down in sustainability performance report

Utility Trailer Manufacturing Co. has announced results from a third-party sustainability performance report conducted by Ramboll, an engineering, design and consultancy company. The report highlights Utility’s environmental, health and safety performance.