As we move from winter to spring, your vehicle maintenance checklist will begin to change to match the season–there will be fewer worries about components or parts freezing, but new issues may spring up (if you’ll pardon the pun) in their place. For this Tech Tip, FE spoke with Kyle O’Dell, director of engineering for Optronics International, who answered our biggest lighting-related maintenance questions.

FE: Moving from winter to spring, what are the most common lighting failures?

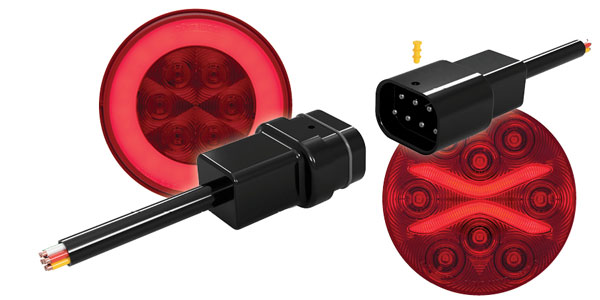

Kyle O’Dell: Connection points from the harness to the lights are among the biggest failure points. Equipment that is used in freezing environments can have added weight of ice on the harness; couple that with vibration and the connection points can take a beating during the winter. While the plastic is resistant to the common chemicals used to prevent icing on the roadways, it is always a good idea to visually inspect the lens to make sure that no damage has occurred with physical impacts from salt or other materials used to treat the roadways.

FE: What’s the proper way to diagnose voltage drops? And how do those voltage drops vary based on lighting position (Tractor headlight vs. trailer lights, for example)?

Generally, the greater the distance from the power source on the vehicle (battery/alternator), the greater the risk for voltage drop. Lights on the front of the vehicle, such as headlights, are very close to the power source and do not see voltage drops that are as severe as lights on the rear of a 53-ft. trailer. The length of run adds resistance, which impedes the flow of electricity. To diagnose voltage drop, use a multimeter to measure the voltage at the power source, then disconnect the harness from a light and measure the voltage at the light. Comparing the two measurements will give you the voltage drop. One thing to point out is that the jacketing on the harness/wires should never pierced with a probe to take the voltage measurements, as piercing the jacket opens up a path for moisture to enter the wires.

FE: From a maintenance management point of view, how often should an electrical maintenance check be performed and to what level of depth?

DOT requires a heavy-duty trailer to be inspected every 12 months, but that’s not really enough.

Fleets will want to refer to the owner’s manual for the trailer’s recommended maintenance intervals and procedures (according to the specific OEM), taking into account their operating environment and vehicle duty cycles.

Other valuable reference sources include the Truck Trailer Manufacturers Association (TTMA) and the Technology and Maintenance Council (TMC) of the American Trucking Associations. TMC’s Recommended Maintenance Practices deal specifically with trailers. TTMA publishes a Trailer Maintenance Manual covering van, platform and dump trailers.

Beyond that, fleets should follow this five-point approach:

- Start corrosion prevention on the day you take possession of the vehicle.

- Train drivers to perform a proper pre-trip inspections (make them a part of the maintenance protocol).

- Train everyone on the team on how to spot corrosion and where to look for it.

- Stick to a regimented planned maintenance schedule.

- Replace incandescent laps with more robust LED lamps.