In the ongoing “ABCs of winter trucking prep” series of tech tips from Bendix, the “B” is for brakes.

“At the wheel ends, the onset of winter weather means paying extra attention to brake components,” said Mark Holley, director of marketing and customer solutions—wheel-end. “During pre-trip walk-arounds, drivers should look at the air brake chamber housings for corrosion or damage that could allow corrosive materials to take hold, and make sure that dust plugs are properly installed. The idea is to prevent corrosion from getting a foothold when these areas are most exposed to hazardous situations.”

In the shop, there are several steps to take to keep braking components healthy in the winter. On drum-braked wheel ends, lubricate the automatic slack adjusters, clevis pin connections, cam tubes, shafts and bushings. It’s a standard preventive maintenance procedure that also keeps moisture from building up and enabling corrosion.

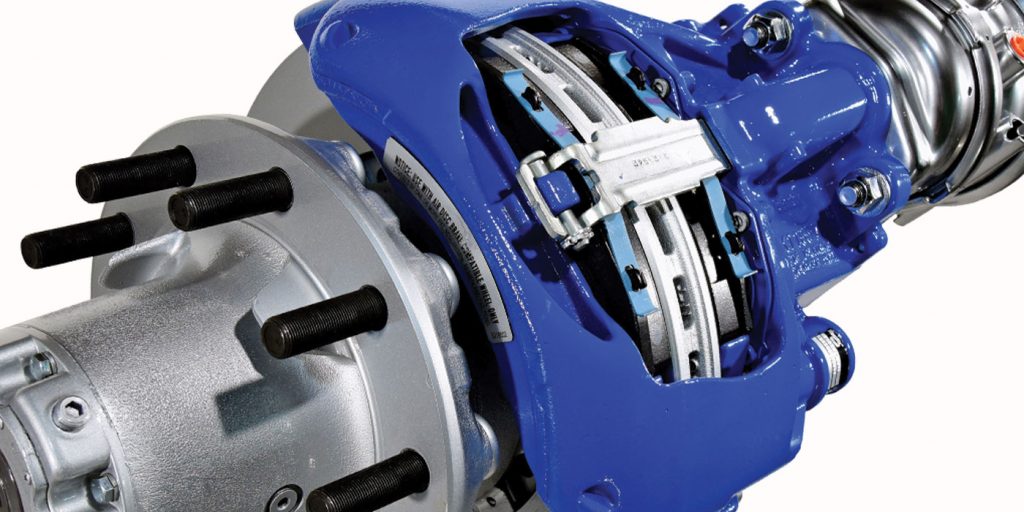

On wheel ends equipped with air disc brakes, check the guide pins and inspect the boots for tears or punctures that could permit corrosion. Replace any pins or boots as needed. Verify that the shear adaptor cover is in place and fully seated. Also, check for free movement of air disc brake pads in the carrier. If necessary, remove them and clean the carrier surface with a wire brush to make sure the brake moves freely on its guidance system.

This article was contributed by Bendix.