Amid headlines of historic change in the trucking industry, one aspect remains the same: Trucks demand uptime. The heavy-duty aftermarket understands this need and supports fleets of all sizes to ensure trucks are serviced and back on the road as quickly as possible. With digital technology expanding the aftermarket’s capabilities, here are three heavy-duty aftermarket trends and how they impact your fleet.

The availability of component data

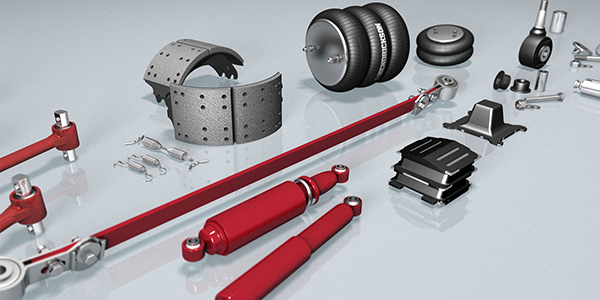

The use of telematics to improve operations has long been established in the fleet management world (engine data to determine the time spent in cruise to increase tractor fuel efficiency, for example), and that value is being expanded to a myriad of truck components. Consider trailer suspensions and wheel ends. Hendrickson’s WATCHMAN advanced wheel-end sensor technology leverages the vehicle area network developed by Sensata Technologies to monitor trailer tire pressure monitoring, wheel-end temperature and wheel-end vibration data.

That data can be used to inform service decisions and even help prevent a major unplanned service by alerting you of a potential issue before it becomes an event that puts your truck and trailer on the side of the road. It also allows you to schedule service with a trusted aftermarket service provider when it fits your schedule.

E-commerce and parts ordering

Getting the right part to the right place at the right time has always been the mantra of the aftermarket, and e-commerce is making that even more accurate and expedient.

“Rich data is what drives aftermarket e-commerce,” said David McCleave, director of aftermarket, Hendrickson. “The trend that parlays into that is: ‘Inventory is king.’ What has changed is that inventory isn’t the ante to the game any more. If you don’t have inventory, you’re just not going to exist. Today, with rich data and e-commerce platforms, those that can identify the right part the fastest–and have it in inventory–is the one who wins.”

McCleave noted that in today’s world e-commerce in the heavy-duty aftermarket is best suited for components that are often replaced such as filters and truck lighting. Yet for more complex components, the tried-and-true aftermarket parts procurement methods are still needed.

People and partnerships make the difference

The more some things change, the more others stay the same. Working with trusted aftermarket partners is key to successful aftermarket service. For all the technology coming into the market, the trucking industry, and heavy-duty aftermarket, is still a people-centric business. With the isolation that came with the pandemic in the past several years, people are getting back to work with people.

“Customers still like to pick up the phone; they still like to talk to people,” McCleave said. “In some cases you have to because you have to be able to say: ‘Here’s the symptom that I’m seeing’ and someone can then understand that and hear and provide a root-cause solution.”

While suppliers like Hendrickson are in the field assisting customers, some lessons learned over the past several years like online-training and virtual meetings can still help. Hendrickson has its Service Academy and Dealer Sales Academy online training resources that allow users to take courses related to the most up-to-date Hendrickson information, guiding technicians through proper maintenance and repair processes in the Service Academy and Dealer Sales Academy users through a deeper understanding of Hendrickson suspension components and applications.

Click here for more on how Hendrickson can be your go-to trusted aftermarket service partner.