Some of the most common violations uncovered during Compliance, Safety, Accountability (CSA) inspections occur from improper maintenance, particularly in the lighting and braking systems. Although these systems have many areas that require attention, there are some simple steps you can take to lower the likelihood of being cited for violations found during an inspection.

Lighting

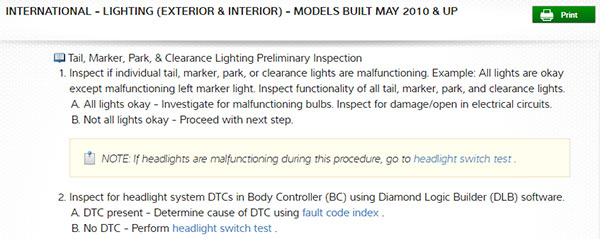

When it comes to lighting, the first step to compliance is to understand the required lights and reflectors. Next, ensure that all of the lights are functional. Inoperable or dim lights can be caused by issues like incorrect bulbs, damaged wiring or corroded sockets, so be sure to inspect the condition of these items. It’s worth paying special attention to the bulbs; it is easy to overlook an incompatible bulb with the incorrect power rating.

It should be noted that later model trucks have multiplexed circuits that can suffer from programming faults as well. Regular inspection of lights can easily indicate when the lighting system requires service. Refer to OEM guidelines or use a resource like Mitchell 1 TruckSeries Class 4-8 repair information software for guidance. As an example, below is a lighting inspection checklist from TruckSeries (Figure 1).

Figure 1: Light Inspection

Brakes

The braking system is another common source of CSA violations and should be inspected frequently as well:

- Lines should be checked for damage and kinks.

- Flexible hoses should allow a reasonable range of movement.

- Linings and drums or rotors should be within operating limits.

- Brakes should be adjusted to Commercial Vehicle Safety Alliance (CVSA) guidelines.

- Components on opposite sides should not be mismatched.

- Emergency braking, brake warning indicators and Anti-Lock Systems (when applicable) should function as intended.

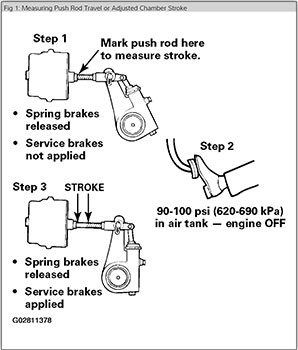

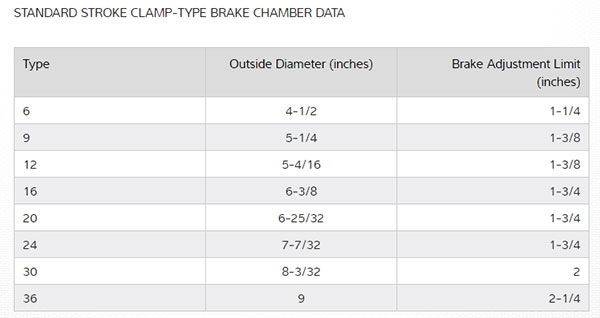

TruckSeries provides detailed checklists, specifications and procedures for brake inspections. A few examples include measuring push rod travel or adjusted chamber stroke (Figure 2) and brake adjustment specs (Figure 3).

Figure 2: Brake Inspection – measuring push rod travel

Figure 3: Brake Adjustment Specs

Make sure that you have all required inspection and service records on hand during the inspection. And be prepared to document any required repairs from a previous inspection.

Proper maintenance is a key to keeping everyone safe on the road, and preventing costly downtime due to a vehicle breaking down or being put out of service. An added benefit of a well maintained vehicle is the reduced chance of being cited for a violation during a CSA inspection.

This tech tip was contributed by Julius Hairston, technical editor for Mitchell 1’s commercial vehicle group.