Truck tire service, especially the inflation process, can be dangerous or even fatal if not performed according to proper procedures. Due to the number of accidents associated with tire inflation, OSHA now mandates that all truck tires be inflated in an acceptable restraining device.

The requirements for safety cages are spelled out in OSHA standards, which define “restraining device” as “an apparatus such as a cage, rack, assemblage of bars and other components that will constrain all wheel components during an explosive separation of a multi-piece wheel or during the sudden release of the contained air of a single piece wheel.”

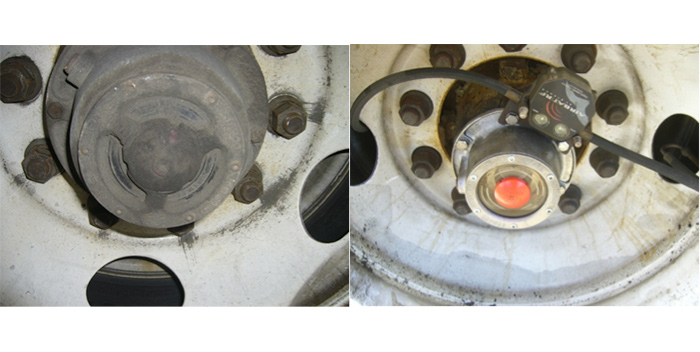

In addition to requiring proper training for technicians, the regulations specify requirements for medium- and heavy-duty truck, OTR, tractor, and super wide tires. The devices usually take the form of a steel base to which heavy-gauge steel tubes are welded. The tubes are spaced to confine a tire and wheel and guard against blown lock rings and rims. Typically, a steel strap encloses one end to prevent tire roll-through. Standard options include three to five steel tubes, and for oversized tires some manufacturers offer robust, fully-enclosed cages with safety door interlock. Portable two-tube designs that handle tire sizes up to 12.00-24 are offered for use on a tire service truck.

A retraining device is mandatory for shops working with tubeless and multi-piece wheels. It is up to the employer to furnish the device, properly train technicians and enforce use of the restraining devices. Some highlights of the OSHA rules for tire servicing equipment include:

• Each restraining device or barrier shall have the capacity to withstand the maximum force that would be transferred to it during a wheel separation occurring at 150% of the maximum tire specification pressure for the type of wheel being serviced. (A tire inflated to 100 PSI with a wheel defect can blow the hub free with up to 50,000 lbs. of force!)

• Restraining devices and barriers shall be visually inspected prior to each day’s use and after any separation of the wheel components or sudden release of contained air. Any restraining device or barrier exhibiting damage such as cracks at welds; cracked or broken components; bent or sprung components caused by mishandling, abuse, tire explosion or wheel separation; pitting of components due to corrosion; or other structural damage which would decrease its effectiveness shall be immediately removed from service.

• Restraining devices or barriers removed from service shall not be returned to service until they are repaired and re-inspected. Restraining devices or barriers requiring structural repair such as component replacement or re-welding shall not be returned to service until they are certified by either the manufacturer or a registered professional engineer as meeting specified strength requirements.

Remember: tires must be completely deflated by removal of the valve core before demounting.