You’ve seen it in the headlines and all over social media: The price of diesel is climbing. Now, more than ever, it’s important to make every penny count by being sure there is nothing negatively impacting your truck’s fuel economy. Underinflated tires are among one of the most common reasons for insufficient gas mileage and can lead to increased wear and tear due to the expanded surface exposure. In fact, tire costs are second on the list of overall fleet maintenance costs with fuel as number one, according to SAF-Holland.

So, to save your wallet from pain at the pump or tire repair costs, keeping an eye on the PSI is a great first step.

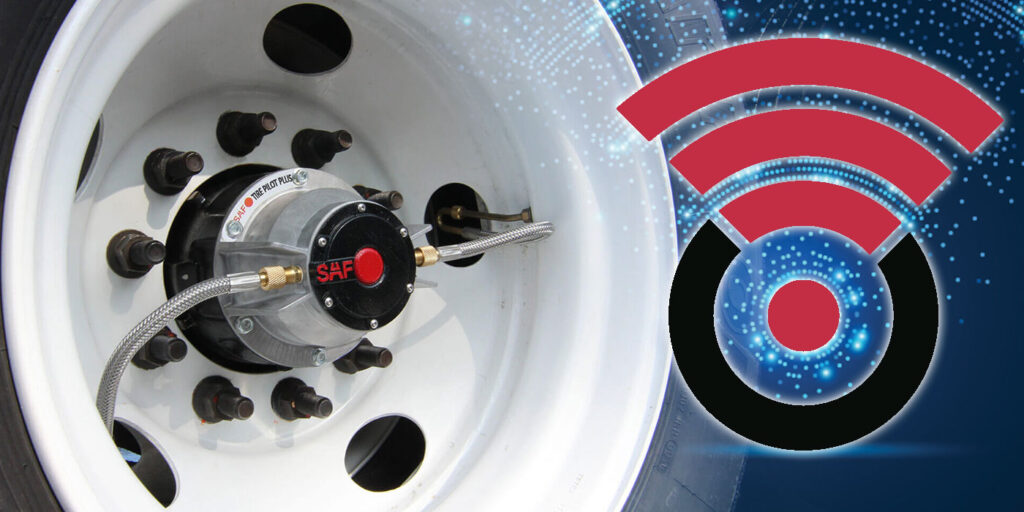

For its part, SAF-Holland combats the rising fuel costs through its Tire Pilot Plus (TPP) technology.. The tire pressure management system actively works to maintain a set and equal PSI for every tire. Whether it be through active inflation or high-pressure relief, the technology responds even while on the move.

“Air leakage/pressure loss will occur over time even if no other events happen to the tire. Thus, a tire management system with pressure maintenance capabilities such as our Tire Pilot Plus (TPP) system will automatically compensate for such leakage issues,” Bill Hicks, SAF product manager, SAF-Holland. “This reduces the driver’s need to constantly check tire pressures, and reduces catastrophic tire issues.”

Tire Pilot Plus instantly combats small leaks that may have been caused by foreign objects and only alerts the driver when there is a timely need to seek service. The system draws its resources from the previously existing trailer air supply allowing for an equalized ride.

“With the advent of ‘smarter’ systems the fleet manager and/or driver will be getting actionable data/alerts that can be used to address issues before they happen. This leads to greater vehicle up time, lower maintenance costs, and greater vehicle safety overall,” Hicks said.

While the technology is great assistance on the road, it is always important for drivers to continue inspecting their trucks themselves. The tire bulge above the road contact patch compared to other tires and the temperature of each tire casting are two factors that may indicate potential tire pressure problems and should be regularly monitored by fleet inspectors.

Since maintaining tire inflation of any vehicle is of utmost importance, fleets of all classes and applications can benefit from a tire management system. The TPP system hardware is relatively common which allows for a broader use and keeps system costs down. However, certain factors can be tailored to a fleet’s specs when it comes to attachment hardware and pressure setting. Unlike the standard TPMS systems, the TPP takes corrective action against rising or falling PSI instantaneously. According to SAF-Holland, typical ROI is less than one year, depending on your application, equipment makeup and duty cycle.