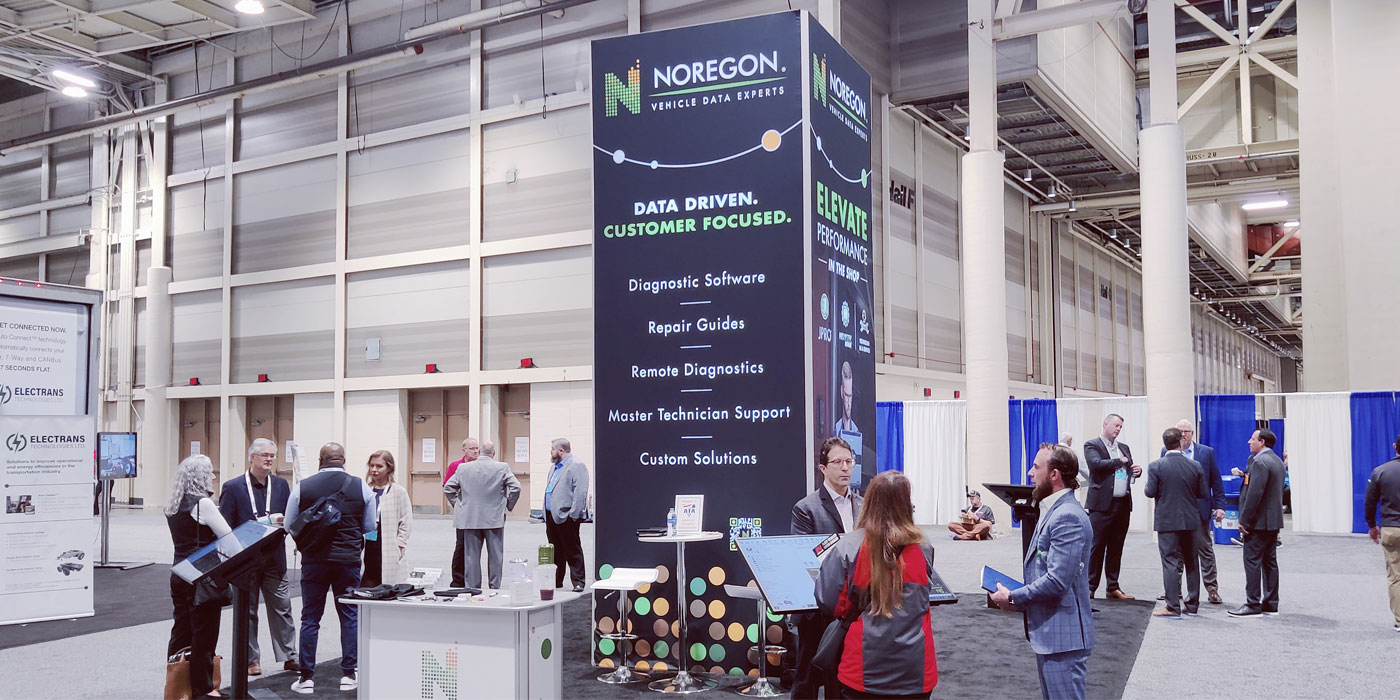

“Today’s trucks are built from such a variety of components that a diagnostic and repair solution covering all makes and models has become a necessity for fleets,” says Shane Gilliam, vice president of sales at Noregon Systems. “Today’s tools need to be standalone solutions for day-to-day use but also integrate with OEM applications for increased functionality.

“The best of these tools will make technicians more efficient by providing rapid diagnostics and pertinent service information for assistance with repairs,” Gilliam continues. “They should be quick to hook up to a vehicle and provide a majority of the features within one or two screens. The most useful tools will be routinely updated with added features and expanded coverage to ensure that the technician can continue to work on the latest components.”

Gilliam goes on to point out that in addition to a diagnosis and repair solution fleets should also equip tools with adapters that allow technicians to work on all vehicles regardless of age. Modern adapters, he adds, work with the latest protocols while remaining backward compatible for older vehicles.

Diagnostics extend to trailers

“Trailers are also getting more advanced,” says Steve Woodbeck, director of product sales at Lite-Check. “ABS, for instance, now requires tools that can read and clear both active and stored faults. The ability to read ABS stored faults while a trailer is in the shop gives the technician information about what is happening while the unit is on the road.”

Trailer technicians are also now using more accurate digital (rather than analog) amperage readers to analyze electrical systems. “This technology in shops allows technicians to see electrical conditions that are deteriorating,” Woodbeck says. “Especially with LED lamps, amp draws are much lower than with the incandescent bulbs they replaced. With modern tools, a technician can easily see amp draw on any circuit.

Significant combinations

“It is very common for a shop’s technicians to work on vehicles that have many combinations of engines, transmissions, brakes, body control modules and HVAC systems, among others,” says Kenneth DeGrant, product manager at Drew Technologies. “Because of the evolution of a significant number of protocols, connectors and ECMs, technicians need to know what components are on a vehicle as well as be familiar with software applications for those components, and which protocol to select for specific model years of vehicles.”

DeGrant, who is an active member of several SAE committees as well as Second Vice Chairman of TMC’s S.12 Onboard Vehicle Electronics Study Group, goes on to explain some of the standards that are in place for vehicle diagnostics. He has also been the TMC RP1210 Task Force Chairman for 16 years and has worked on the SAE J2534 standard. Both standards relate to Vehicle Diagnostic Adapters (VDAs) and PassThru Reprogramming devices also known as a Vehicle Communication Interface (VCI).

“The heavy-duty industry first standardized on the J1708/J1587 protocol and six-pin round Deutsch connector in the late 1980s because of the various ECMs on vehicles,” DeGrant relates. “Since then, a CAN-based protocol called J1939 became the current standard and is rapidly replacing J1708/J1587. Another CAN-based protocol called ISO15765 (mandated on OBDII vehicles in 2006) is also appearing on medium- and heavy-duty vehicles and there have been two revisions of the Deutsch nine-pin round connector to accommodate three CAN channels as well as increased data bus speeds.”

According to DeGrant, the horizontal nature of the medium- and heavy-duty truck sector required OEMs to standardize on an Application Programming Interface (API) for the use of VDAs/VCIs for their diagnostic and reprogramming software. This led to the development of the TMC RP1210 standard.

Given the growing complexity of vehicle systems and components, diagnostic tool suppliers are offering training for fleet technicians. “The best tools are intuitive enough that users can learn them quickly, but we also offer training options for continuous education to master the tools and become more efficient,” states Noregon’s Gilliam. “A technician who has no experience with a tool, for example, could learn to be proficient within an hour or two and feel comfortable using the tool for a majority of diagnosis and repair purposes.

“Ongoing training should be provided in a variety of ways to fit the technician’s schedule and desired pace of learning,” Gilliam adds. “For example, Noregon offers multiple interactive online webinars each month as well as online training videos. For on-the-spot troubleshooting, comprehensive instructions within a user guide are built into the software and a U.S.-based support center is also available to quickly resolve any issues.”

“We offer tech support on the phone, and with the new Android tablet, we can remotely interface with customers, see what they are seeing and control their tablet remotely with them on the phone,” CanDo International Marketing Director Victor Rivilla explains.

Lite-Check’s Woodbeck says any technician can spend just a minute to get comfortable with the remote buttons needed to perform a trailer inspection using it tools. “We offer support through our customer service department where we can work with the technician to help find out

Bee Line Co. National Sales Manager Dan Santry says his company’s WindSpeed 7500 software has integrated help videos and service manuals designed to make training straightforward and simple. “Several videos in the help section guide the technician through specific procedures,” he relates. “Bee Line Co. also offers hands-on courses at a fully equipped training center.”