If the engine is the heart of your powertrain and the transmission is the shifting brains behind the operation, then the axle is the muscle, propelling your truck down the highway. While the engine and transmission get much of the spotlight, the axle plays a key role in increasing efficiency—in both proprietary powertrains and those of your own spec.

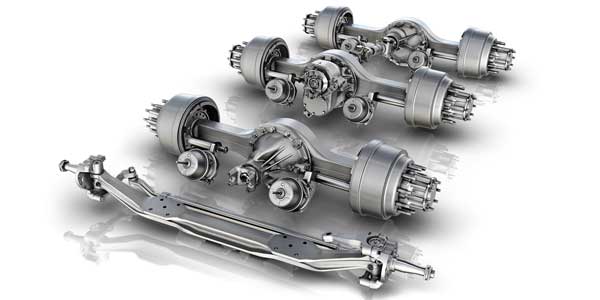

As with any equipment, properly pairing your axle to the engine and transmission depends on your application. Consider the PACCAR 40k axle, which targets line haul applications. Its inter-axle differential, rear axle ratio range and gross combination weight rating are optimized for use with the PACCAR MX engine and transmission. This PACCAR proprietary offering allows the manufacturer to develop the entire powertrain, maximizing the reliability, efficiency and weight of all components, according to PACCAR Vice President Landon Sproull.

“There are three key design innovations that make the PACCAR 40k axle efficient,” Sproull began. “First, the pinion-thru-shaft design eliminates a gear mesh to create a more efficient method of splitting torque between the two drive axles, resulting in reduced friction and increased efficiency. Second, the pinion gears in the axle are laser-welded as opposed to bolted. This smooth surface design reduces oil churn—again, improving efficiency. Lastly, the axle uses passive lubrication distribution to dynamically adjust lube levels in the axles at speed further reducing oil churn.”

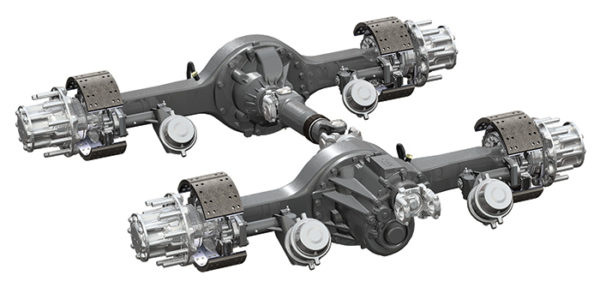

By offering integrated proprietary powertrain packages, manufacturers are able to offer powertrains that leverage fine-tuning that allows each component to work in concert, boosting productivity and efficiency. The Integrated Detroit Powertrain (IDP) Fuel Economy Package requires the correct Detroit rear axle and rear axle ratio combination to support the downsped powertrain. Part of the process of selecting powertrain components includes of a combination of powertrain components including the Detroit DD15 or DD13 engine, Detroit DT12 Automated Manual Transmission (AMT) and Detroit rear axles with properly selected rear axle ratio.

“The most common areas of the axles that drive fuel efficiency are generally any designs or technologies, internal or external, which help improve the ability of the axle to reduce parasitic loss,” explained Brian Daniels, manager of Detroit powertrain and component product marketing.

Daniels pointed to the following advancements in technology and design that allow the axles to integrate efficiently into the powertrain.

- Gear set and carrier optimization for each axle;

- Hypoid design featuring a pinion centerline below ring gear centerline for enhanced durability; and

- Low-viscosity and friction-optimized oil for reduced parasitic loss.

Additionally, Daniels detailed the Detroit’s optional Axle Lubrication Management (ALM) system, which features a ring gear cover with a valve that actively regulates the oil level. This reduces the churning associated with the ring gear moving through the oil. “Combined with advanced pinion bearing design,” Daniels said, “ALM further reduces parasitic loss for up to a total 1.5% fuel economy improvement compared with classic Detroit axles.”

Where proprietary powertrains typically focus on an inch-wide, mile-deep product range and options, Dana says it approaches the entire market with a broad variety of axle solutions, offering a robust range of products and specs that include axles with the fastest axle ratios.

“Our engineers work closely with truck manufacturers to make sure that the engine, transmission, driveshaft, and axles work as a finely tuned, integrated unit to deliver the specific performance needed for any given application,” said Steve Slesinski, global director of product planning for the commercial-vehicle market at Dana Inc. “Dana’s integrated drivetrain system features an efficient and robust power divider unit coupled with heavy-duty u-joints, bearings, and yokes to accommodate faster axle ratios and allow for up to 40% higher input torque compared to customary overdrive transmission drivetrain configurations. This avoids many special engine torque restrictions and extends bearing life to maximize vehicle uptime during the vehicle’s intended life, and avoids most failures during vehicle launch events.”

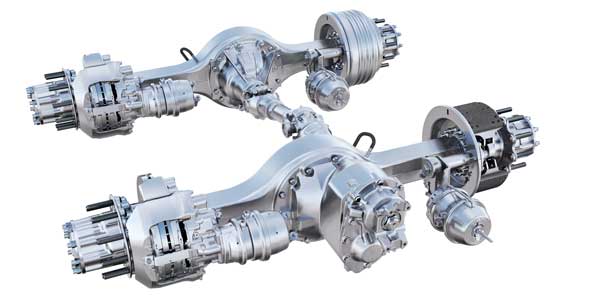

Slesinski noted that Dana’s driveline systems—driveshafts, u-joints and axles—allow vehicles to run at highway cruise speeds at significantly lower engine RPMs than previous powertrain systems while still reducing weight and increasing axle efficiency. In support of efficiency claims, Slesinski pointed to Dana’s AdvanTek 40 tandem axle, which was developed along with the SPL 350 driveshaft and SPL 250 inter-axle shaft.

“Fuel efficiency gains can be achieved by reducing weight, optimizing lube flow, and minimizing power losses,” Slesinski said. “The AdvanTek 40 features a light-weight carrier, special designed spiral bevel gearing and higher efficiency bearings in addition to a patented lube meter and axle enclosure system that contributes to reduce power losses while reducing lube volume requirements by up to 10%.”

Clearly, reducing oil-related efficiency losses is a top priority for axle manufacturers. Dana has patented a lube-metering device that allows the high efficiency bearings to operate at the optimum rate.

“Through differential carrier and axle housing design improvements, we reduced excessive lube volume and validated our axle designs to perform with the industry’s most efficient axle lubricants such as the extra-fuel-efficient synthetic XFE 75W-90 and XFE 75W-85 lube,” Slesinski noted.

Looking for a quick refresher on downspeeding details? Click here for the downspeeding lowdown.

Working closely with OEMs to optimize powertrain configurations is a big focus for Meritor. “We work to understand the engine and transmission requirements to ensure our axles are designed and applied correctly to meet a variety of user requirements, specifically weight, fuel efficiency, durability and performance,” said Dawn Clegg, director of product strategy for Meritor’s North American axle division.

In terms of axle efficiency, Clegg pointed to several Meritor axle design aspects that address fleets needs. First, Meritor’s lube management system helps to reduce churning losses. Second, laser welding components eliminate fasteners to further reduce churning loss. Third, optimized gear design and fuel efficient bearings seek to give MPG a boost.

“Meritor works extensively to understand these factors for a specific duty cycle and we develop solutions to impact efficiency,” Clegg said.

When considering axles that boost your efficiency, you’d likely want to extend those efficiency gains out to your wheel end through the spec’ing of high-efficiency bearings. Click here to read more about that.