It’s that time of year again. Fall is upon us and on the horizon is colder weather. Next spring, the welcome warmth of the season will bring changes as well. And with those seasonal shifts come conditions that can sideline trucks. That’s a prospect that any fleet manager knows can raise costs for unscheduled repairs and breakdowns. There is also the negative impact that downtime has on customer satisfaction when a load can’t be delivered on time.

There are, however, a number of proven approaches to preventing cold and warm weather related problems. Here are some tips from experts about electrical, brake and air systems, and lubricants.

Electrical

“There is a rule of thumb is that electrical systems should be checked at least twice a year, in spring before a fleet goes into the heat of summer and in fall before you go into the cold,” said Larry Rambeaux, sales application engineer at Purkeys.

“While it’s hard to determine if any components should be replaced in a fleet wide campaign, we do see many avoidable electrical system breakdowns that could have been prevented by a good maintenance program,” Rambeaux continued. “The issue is that fleets either don’t perform inspections and testing on a timely basis or they don’t repair the issues that are found.”

Braking and air systems

Freeze-ups, wheel-end issues like out of compliance brake stroke, and increased stopping distance are all potential issues that can arise by not performing preventive maintenance on brake and air systems in advance of colder weather, related Brian Screeton, supervisor of technical training at Bendix Commercial Vehicle Systems.

“Ahead of cold weather, regular tank drains to check for signs of excessive water contamination would be an indication that the air dryer needs service,” Screeton said. “That will give the air system time to work out any water that’s downstream. Also check for proper routing of the discharge line for a gradual and consistent descent from the air compressor to the air dryer, with no dips in the line that can trap water.”

While those practices will help keep the air system dry, Screeton cautioned against using any air brake system additives, calling them a “short term fix at best” that has the potential to damage seals and O-rings in the valves of the air system.

Preventing water contamination in advance of colder weather on brake system components like slack adjusters and s-cams requires regular lubrication, Screeton noted. “Pushing water and contamination out of these components helps prevent freeze-ups that will hinder correct operation,” he said.

“No matter what the temperature is outside, periodic inspections of air systems and wheel ends are the key to catching potential issues before they cause downtime and added repair expense,” Screeton added.

Lubricants

With changes in the weather, Kevin Carabell, technical services specialist at Chevron, advised that fleets consider changing the engine oil and using a different viscosity grade based on temperature.

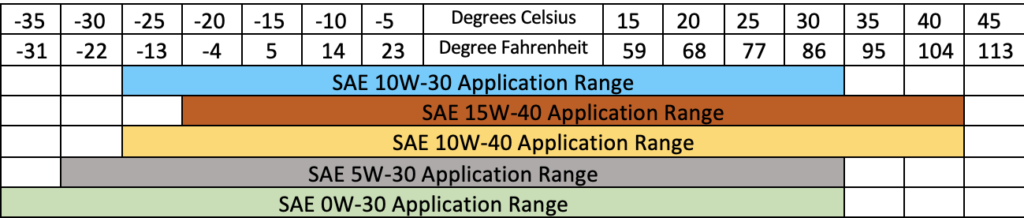

“If your operating climate sees extremely hot weather, for example long spells above 86 degrees F, consider changing SAE 10W-30 for an SAE 15W-40 oil in the late spring,” Carabell said. “That will protect your engine when the summer heat comes around.

“On the other hand, if winter weather where your trucks operate cools down to well below zero, then it’s best in the fall to put in an SAE 5W-30,” Carabell added. “If your equipment is operating in subarctic temperatures below -30 F, you could even consider using an 0W-30 oil.”

Application ranges by temperature for common SAE viscosity grades:

According to Carabell, it’s also a good practice to check a few other lubricant and fluid related items seasonally, including:

- Oil pressure to ensure adequate filter flow and pump operation

- Transmission fluid level

- Differential fluid levels

- Coolant condition

Where can fleets find out about best practices for seasonal maintenance?

System and component manufacturers offer a range of resources that can help fleets put effective seasonal maintenance practices in place. Equipment providers also say to always refer to manufacturer’s recommendations for service and inspection intervals.

The Technology & Maintenance Council (TMC) has a large number of Recommended Practices with information that covers best maintenance practices for properly inspecting and repairing equipment, Larry Rambeaux noted as well. The RPs are handy for fleets to reference, he added, as they address specific aspects of trucks and trailers.