The winter months bring some challenging conditions for commercial trucks. Snow, rain and mud seem to get into everything, particularly the brakes. All that wet muck tends to find its way into the wheel-end brake assemblies, adding a nice layer of grinding material and creating less-than-ideal operating conditions.

Grooves are worn in drums or rotors from the road grime. Lubricated surfaces on brake hardware gets washed clean, resulting in rust and binding. The list of potential problems brought about from water and road debris goes on and on. Winter is simply a tough time to be a brake.

But honestly, brakes have challenges all year round. While some difficulties are connected with the winter weather, other issues may happen at any time and can cause poor brake operation or brake failure.

Potential hydraulic brake issues

Let’s look at three potential concerns that may affect the braking system on medium-duty trucks equipped with hydraulic brakes.

Most truck drivers know that there is a difference in pedal feel between air brakes and hydraulic brakes. However, with the advent of antilock brakes on vehicles with hydraulic brake systems, the pedal pressure is a little trickier than in the past. With pre- or early antilock brakes, when pushing the brake pedal to the floor, pressure could be clearly felt in the pedal and the wheels would begin their “dance” as the brakes were applied and released to prevent a skid.

As brakes became more powerful and efficient, less effort is now needed to slow and stop the vehicle. Consequently, drivers may end up applying too much brake pedal pressure in an effort to slow the truck and cause an antilock stop. Such stops, in turn, result in faster wear of the brake lining. Thus, when inspecting brakes, it’s recommended to use a scan tool to determine the number of antilock stops and if excessive, explain proper operation to the driver.

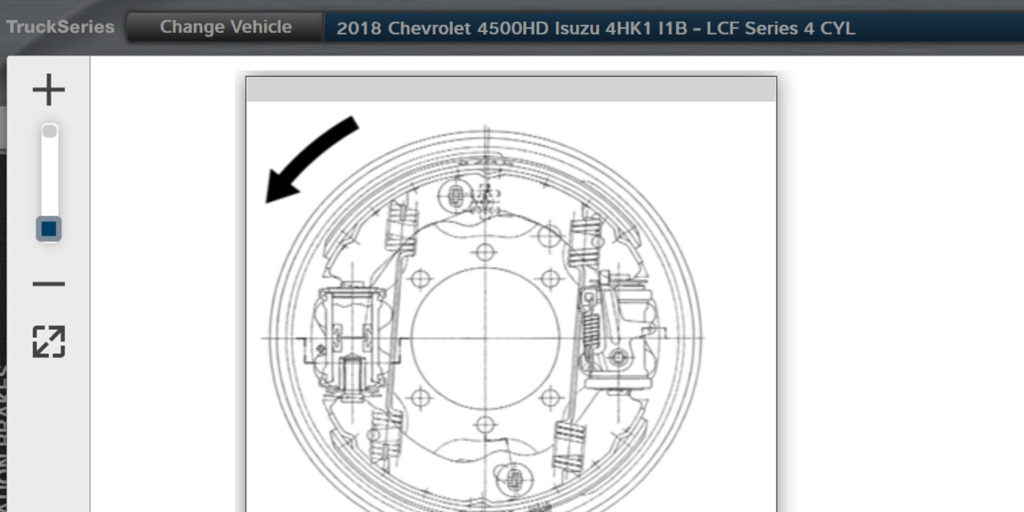

Next, wheel ends also play an important role in proper brake operation and wear. When inspecting the wear patterns on brake shoes or pads, note any irregularities in wear from side to side as well as brake lining worn at an angle on a particular wheel. Loose or damaged wheel bearings may allow the linings to contact the drum or rotor at an angle causing increased wear on one side of the lining contact surface. Inspect the wheel bearings for wear or improper adjustment and correct as needed.

In the process of inspecting or replacing brake linings or pads, the connecting hardware and hydraulic cylinders may get overlooked. Any area in the brake with moving parts will wear, corrode or just break. Whenever brakes are disassembled for repair, make sure to inspect springs, adjusters, cylinders, backing plates and other hardware for wear or damage. When any of these components are not up to standard, poor performance and uneven wear will likely take place.

So, while the winter months present brake system challenges, it cannot be stressed enough that keeping the brake system in good operating order all year is of the utmost importance. On final note, even if you are familiar with the brake system in question, be sure to review your truck service information resource, like TruckSeries from Mitchell 1. You can gain valuable insight about the vehicle under inspection and reminders of those parts of the system that may cause braking concerns.

Additional tips for repair and maintenance of Class 4-8 trucks may be found in the Mitchell 1 ShopConnection Truck blog.