It’s been part of the specification vernacular for many years. As a powertrain-focused strategy for improving fuel economy, downspeeding has been of interest to fleets looking to lower fuel costs. For manufacturers, it is also a means of meeting efficiency and greenhouse gas emissions regulations.

The concept itself is simple. With downspeeding, the rear axle ratio is sped up in order to lower engine RPMs. Fuel efficiency improvements then result from an engine that only needs to generate minimal horsepower to maintain a desired road speed.

Like any specification decision, however, there are operational considerations for fleets, and the need to fully understand how engines and transmissions are designed for downspeeding, the latest ratios and the fuel efficiency gains that can be expected. Recently, Fleet Equipment assembled a group of experts to discuss those subjects. On the panel were:

Dale Kwasniewski, Senior Director, Engineering, Cummins-Meritor

Steve Mastroianni, Senior Manager, Product Planning, Dana

Mike Young, Marketing Manager, Engines, Detroit

Johan Agebrand, Director of Product Marketing, Volvo Trucks North America

Jacob White, Director of Product Marketing, Peterbilt

What operational considerations should fleets have when specifying downsped powertrains?

Kwasniewski: The ideal application for downsped engines is linehaul vehicles, but routes and terrain are also factors. Without it, when trucks struggle to maintain speed when climbing grades with a full load, downshifting causes the RPMs to increase burning more fuel.

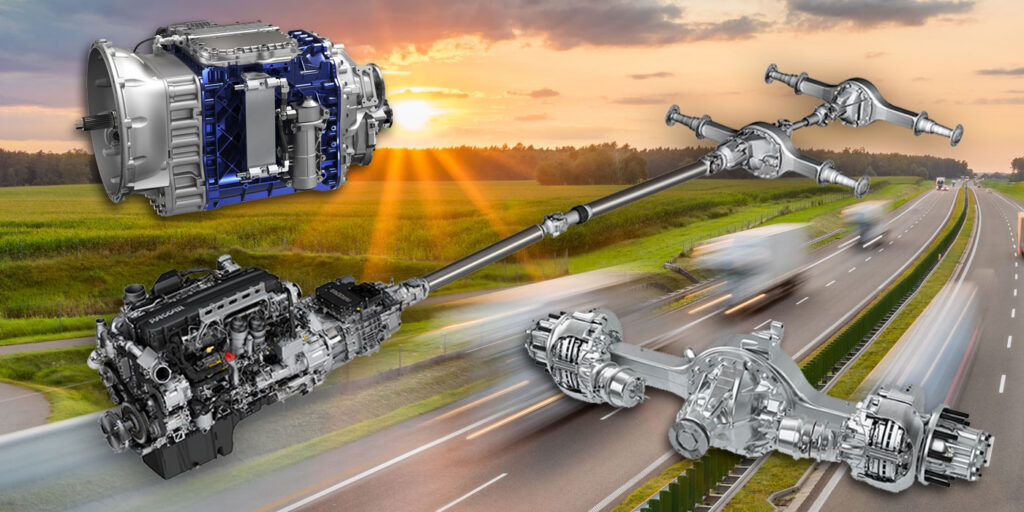

Mastroianni: Fleets considering a downsped powertrain must consider how its key components – the engine, transmission, driveshaft, and axle – work together to deliver the optimum power, performance and reliability for a given application and duty cycle. That can include a lighter weight tandem axle or a heavy-duty single drive axle that offers the fast ratios required to fully leverage the efficiency benefits, and a driveshaft that can withstand higher torques.

Young: Route types and applications should be the first considerations when selecting a powertrain spec. Fleets can also select either direct drive or overdrive transmissions based on weight, speed, and typical terrain. Direct drive transmissions operate more efficiently on flat terrain where top gear time is high, but if a route has significant elevation changes an overdrive transmission can be the more efficient option. Additionally, automated transmissions enable the engine to hold a gear in lower RPMs without downshifting, maximizing top gear time and low RPM at road speed.

White: A key to taking full advantage of downsped powertrains is driver training. It is critical that drivers understand how the truck is intended to be operated and allow it to utilize technology such as predictive cruise control.

Agebrand: Fleets need to discuss how a specific powertrain is best used because all downsped powertrains are not the same. Another important topic is driver training so they understand how the truck should be driven. Without providing that information you can easily lose all the savings that were expected.

How are engines and transmissions for designed for downspeeding?

White: A fully integrated powertrain is optimized for fuel efficiency in over-the-road applications. Engines and transmissions utilize intelligent controls that ensure optimal power delivery for efficient operation and startability.

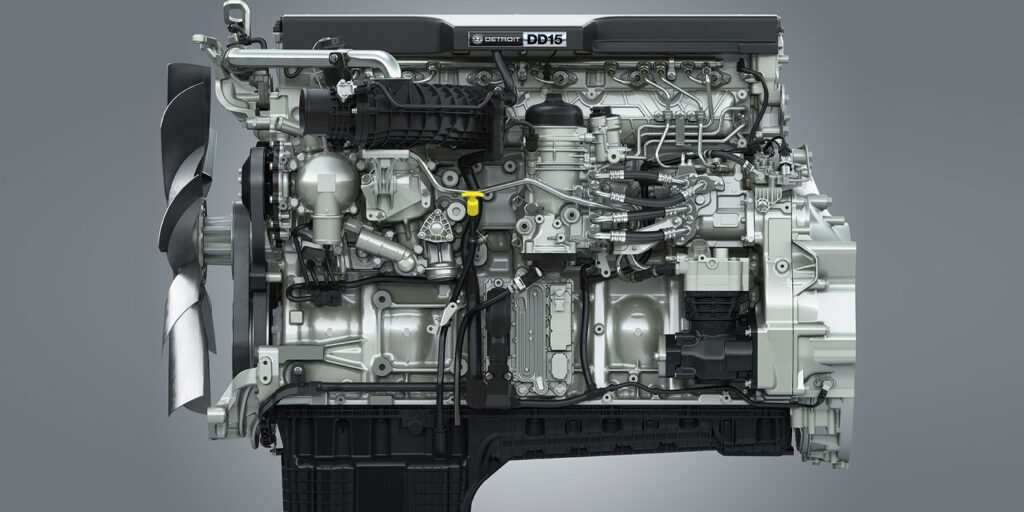

Young: Engines have been consistently tuned over the years to provide high horsepower and torque ratings at lower engine RPMs. As engines downspeed over time, transmission shift maps account for this and keep the engine at the ideal point in the torque curve, even as it is pushed into operating at lower RPMs. Additionally, it takes the entire system working together. If ratio adjustments are not made to keep up with the changes in RPMs, performance could suffer.

Agebrand: Today’s engines have higher torque, which means they also have higher power at lower RPMs, so the goal is to utilize this torque and power in the right way, not overutilize it and waste fuel while also not underutilizing it and not capturing its full potential. The other aspect is that automated manual transmissions shift faster, and that helps with downspeeding since only the most experienced drivers would select similar shift points.

Kwasniewski: Electronic engines are designed to put the fuel island, the most efficient part of the fuel map, between 1,050 and 1,350 RPM. Operating on the lower RPM side of the fuel island provides additional benefits through reduced parasitic losses. The slower an accessory drive spins, the less horsepower is consumed at steady state operation. Additionally, with a transmission geared to land near the fuel island during a downshift, and with approximately 300 RPMs between gears, the shift logic keeps the engine operating as close to the fuel island as possible.

What are the latest ratios for long-haul applications?

White: Fleets looking to achieve the highest levels of fuel savings can specify downsped powertrains with rear axle ratios as fast as 2.47 when paired with an overdrive transmission.

Mastroianni: Dana’s fastest axle ratio to support downspeeding is 1.95:1. Additional downsped axle ratios include: 2.05, 2.16, 2.26, 2.31, 2.39, 2.47, 2.53, 2.64, 2.79, 2.85, and 2.93.

Young: The fastest available ratios from Detroit are 2.16 for direct drive transmissions and 2.64 for overdrives.

Kwasniewski: The Cummins-Meritor 14X HE tandem drive axle is available with ratios from 2.15 to 3.90. The 17X HE single drive axle is available with ratios from 2.06 to 3.36. Ratios lower than 2.0 are only for testing at this point.

Agebrand: For a truck traveling up to 68 MPH and carrying 80,000 lbs., our recommendation is a 2.15 direct drive.

What fuel efficiency gains can be expected?

Agebrand: A general rule of thumb is that downspeeding gives you about a one percent fuel savings with a 100 RPM lower engine speed.

White: For every 100 RPM reduction in engine speed at cruise, we typically see a one percent improvement in fuel economy.

Mastroianni: Use of a downsped system in a typical linehaul duty cycle enables increased efficiency by up to two percent, and fleets can anticipate a savings of over 1,400 gallons of fuel over a five-year period.

Young: The gains depend on where a fleet is starting from. If you have trucks in long haul applications that have a 3.08 or higher ratio, there is likely considerable efficiency gains being left on the table. Ratio steps generally bring between 0.5% and one percent reductions in fuel consumption, everything else staying constant.