Tire management is important and data is important, yet when the two come together it can be overwhelming. Tire costs often top the list of major expenses (if not take pole position) and so much data is coming at you from so many components that it can be difficult to weed through the details. That’s why suppliers are bringing increasingly intelligent tire pressure-focused telematics to trailer telematics platforms.

“The data you want is the data that’s actionable,” explained Steve Hampson, director electronic controls, Hendrickson USA, which is set to roll out its WATCHMAN wheel-end sensor technology for trailers. The initial product offering will include trailer tire pressure and wheel-end temperature data that is communicated to the fleet via the trailer telematics system.

“We transmit a lot of data, together with telematics providers, but we distill that data down to the most important information,” Hampson continued. “Let’s say you have a fleet of 100 trailers, and you want to know about the ones that have problems. We focus on those problem assets and provide an alert back to the fleet office that says, ‘There is a problem with trailer 1, 2, 3, 4, etc.’ Those are the ones you focus on.”

Those notifications can be sent in an email, text messages or displayed on a dashboard. As far as what fleets are being notified of, the starting point is tire pressure problems. Automatic tire inflation systems, like Hendrickson’s TIREMAAX tire pressure control systems, keep trailers rolling when there is a small leak. The issue is that they work so well that you might not know the tire has a leak. WATCHMAN tells you that.

“If it’s a critical tire pressure problem, maybe you want the driver to pull over immediately, but if it’s a slow leak that we’ve detected and notified you of, maybe the driver delivers the load and then proceeds to a place where he can get it repaired,” Hampson explained. “That way he’s not on the side of the road. WATCHMAN provides the fleet manager with information that allows them to make an informed decision–does the tractor trailer need to stop or can it be repaired soon?”

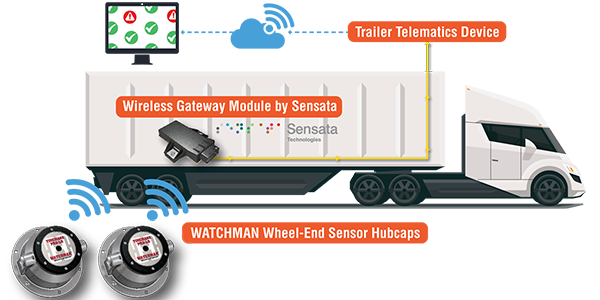

The way WATCHMAN works is that hubcap-mounted, battery-powered wheel-end sensors transmit wireless RF signals to the gateway module, collecting the data and acting as the trailer’s communication hub. The information will be transmitted from the gateway module to the trailer telematics device for transmission to the fleet’s back office.

Hampson was quick to note that information isn’t just given when the trailer is in motion. Overall tire pressure health checks are available when the trailer is in the yard too.

“Quite a few fleets have said to us, ‘What we really want is a health ready warning: Is that asset, is that trailer ready to roll? Are there any problems with it? If there are problems,I don’t want to put it out on the road, I want to fix it first.’ Our WATCHMAN system records tire pressure data and will notify you accordingly. Some of the telematic providers we’re working with have a battery backup on the trailer so that they can power up the system while it’s parked and send that information before you pick up the trailer.”

These two examples just scratch the surface of what’s possible with WATCHMAN. Click here to learn more about Hendrickson’s upcoming WATCHMAN wheel-end sensor technology for trailers.