Automated manual transmission (AMT) and automatic transmission manufacturers are crushing assumptions and setting new expectations in all trucking industry applications. Automatic transmissions are getting smarter and, in the AMT world, gone are the days of clunky, reverse-engineered AMTs. Today’s AMTs are, as PACCAR Vice President Landon Sproull put it, “purpose built.”

“The gearing—overall ratio and step sizes—are suited for the job, and the gearbox architecture is right-sized as compared to preceding product platforms,” he said. “The previous AMTs were converted versions of manual transmissions.”

“Today’s automated transmissions are smarter, lighter, more efficient, more reliable and have longer maintenance intervals than ever before,” agreed Charles Ganske, product planning leader for Eaton Cummins Automated Transmission Technologies. “Fleets benefit from all these areas through fuel savings, maintenance costs and improved driver satisfaction.”

We asked the top truck transmission manufacturers to prove it by rattling off some of the latest equipment evolutions. Here’s what they said:

Allison Transmission: “Allison introduced FuelSense 2.0 with DynActive Shifting to optimize the balance between fuel economy and performance,” said Branden Harbin, managing director of global marketing for Allison Transmission. “FuelSense 2.0 uses a learning algorithm to continuously find the ideal balance of fuel economy and performance for a fleet’s duty cycle, helping our customers’ vehicles operate more efficiently.”

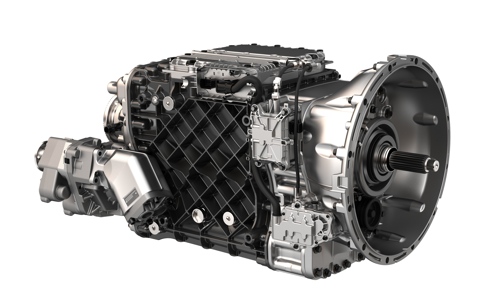

Detroit: “In addition to myriad quality and durability gains, and service interval reduction initiatives for the Detroit DT12, we have also introduced a rear PTO option and expanded the variety of PTO ratios,” said Mike Stricker, director of sales for Daimler Trucks North America (DTNA). “We also introduced a more fuel-efficient variant that offered ‘Super Finished’ gears and reduced lubrication.”

Eaton Cummins Automated Transmission Technologies: “We’ve worked hard on the software and controls integration between the engine and transmission,” Ganske said. “For Endurant HD, a great example of the powertrain integration on intelligent features is Cummins’ On Ramp Boost technology and the performance advantage of engine and transmission software working together. We also continue to improve and tune features like predictive gear shifting as we receive feedback from customers.”

Mack Trucks: “We’ve released new tuning and software to match our latest engine torque and power curves, which helps the mDrive keep the engine in its sweet spot providing the best fuel efficiency, power and performance,” said Stu Russoli, Mack highway product manager. “On highway models, the mDrive can be placed in three driving modes: Maximum Economy, or EMAX, for the most fuel-efficient power, acceleration and shift strategy; Economy, or Econ, for a balanced strategy between maximum fuel economy and performance with minimum driver intervention; and Performance, or Perf, which offers an aggressive shifting strategy for maximum power, acceleration and gradeability.”

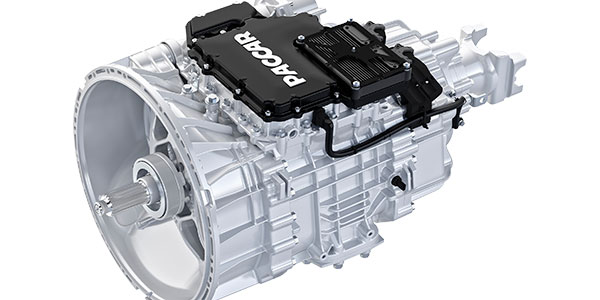

PACCAR: “The new transmissions such as the PACCAR 12-speed Transmission continue to make appropriate shift decisions,” Sproull said. “The system uses the engine power, throttle position, vehicle speed, engine speed, grade, vehicle mass [weight] and lateral acceleration to make basic shift decisions. This is further enhanced when the system uses predictive data [look-ahead, road profile, etc.] to make even better decisions.”

Volvo Trucks North America: “We provide I-See, a predictive cruise control function that is fully integrated into the vehicle,” said Johan Agebrand, director of product marketing for Volvo Trucks North America. “Additionally, we also provide options such as Power Launch and the ability to ‘rock’ the vehicle back and forth in an effort to try to maneuver out of a stuck truck condition.”

Shifting strategies

Advanced shift management capabilities are driving much of the AMT’s evolution.

“Our shifting strategy has evolved since 2001—it adapts to truckload, drivers and topography,” Volvo Trucks’ Agebrand said. “The 14-speed Volvo I-Shift transmission supports multiple reverse speeds and it can support all truck applications. We see it continuing to evolve and we will continue to improve gear shifting, feel and performance. We will continue to develop new software features and will also continue to improve the quality, safety and performance of our products.”

Optimizing the shift strategy, and even predicting the series of most efficient shifts for the road ahead is where a bulk of today’s transmission technology is heading.

“Many AMTs have a core set of features like neutral coast, hill start aid, etc., but it’s how well the engine and transmission communicate with each other that creates a superior driving experience,” Eaton Cummins’ Ganske said, which is why the powertrain integration story was paramount when AMTs were gaining ground several years ago.

That integration has only gone deeper between the engine and transmission, which shows in the pairing’s feature set. When asked for a few examples, DTNA’s Stricker ticked them off the list. “Hill Hold, eCoast, Adaptive Cruise Control to 0 MPH (ACC), engine brake integration, weight estimation, grade sensing and maintenance monitoring based on oil temps,” he said, and then shifted to Intelligent Powertrain Management (IPM) benefits. “IPM integrates pre-loaded terrain maps and GPS into engine and transmission functions to know the route ahead and use the momentum of the truck most efficiently to reduce fuel consumption.”

Allison’s automatic transmissions have also evolved to improve fuel efficiency.

[A quick refresher on the AMT/automatic transmission difference: AMTs use a clutch to disengage the drivetrain, like a manual. However, the automated clutch actuator electronically controls it with no input needed from the driver. Automatic transmissions use a torque converter, where the engine and drivetrain are connected by a fluid coupling.]

Allison Transmission’s Harbin noted that nearly half of the transmissions it delivers are equipped with FuelSense 2.0, which includes Neutral at Stop and Acceleration Rate Management.

“Neutral at Stop trims fuel consumption and emissions by reducing or eliminating the load on the engine when the vehicle is stopped. This will support OEMs in achieving GHG 2024 and 2027 phase-ins,” Harbin said. “Acceleration Rate Management controls engine torque at launch, standardizing vehicle launch performance and the resulting fuel economy at launch, regardless of driver behavior. In addition to five levels of acceleration control, this feature provides the option for further precision through customized calibrated rates for vehicles operating in non-CARB adopting states.”

These features are much more than a marketing bullet point—they add up to real operational savings. It’s important you know how they function and communicate that to your drivers.

“The Mack mDrive’s drive modes and parameter settings are available to everyone, but not everyone utilizes them to the best advantage for the best fuel efficiency or performance. New parameters can be set on a truck at the dealer and even through Mack Over The Air, should a truck change routes,” Mack’s Russoli said. “For example, a truck driving a new, more demanding route can be updated to better manage the hills. Conversely, if the truck goes to less hilly terrain or longer highway runs, it can be updated to the maximum economy mode for the best fuel efficiency. In addition, there is a lot of data available from the engine and transmission that can be used and analyzed to make customers’ routes, drivers and trucks more efficient.”

DTNA’s Stricker noted that driver communication is often key to reaping the AMT ROI.

“Fleets don’t usually offer their drivers control of the speed settings. As a result, drivers are more likely to override some of the functionality. With control of the speed hysteresis, they could improve the fuel efficiency benefit when conditions allow, such as low traffic,” he said. “Training on this feature is key to success with IPM.”