Determining the best tire pressure to run in your steer, drive and trailer tires should be very easy, but in reality it can be very confusing. Proper tire inflation pressure is critical for many reasons: optimizing tire footprint, maximizing treadwear; keeping tires running cool; maximizing retreadability; increasing fuel economy; minimizing irregular wear; and reducing tire related service calls.

Underinflation is always a much more serious issue than running a little overinflated. When tires run underinflated, the sidewalls have excessive flexing, which generates additional heat. Heat is a tire’s worst enemy. In addition, the tire footprint becomes “longer,” which means more rubber on the road. This extra rubber generates additional heat. In addition, the longer footprint in combination with the hotter rubber leads to picking up more puncturing objects. More punctures seriously increase your fleet’s tire related roadside service call costs.

Obviously, air is what carries the load in tires. The issue for fleets is that loads tend to cover the full spectrum—from light to heavy. Some fleets may haul heavy rolls of paper on the trip out and return with a trailer full of lighter weight potato chips. The tire pressure recommendation is based on the worst-case load the individual tire will see in real life. Fleets don’t have the luxury of changing the tire pressure of 18 or more tires every time there is a new load. The only solution is to use published load/inflation tables for worst case load scenarios when determining the recommended tire pressure. The tire pressure recommendation will most likely be different for steers, drives and trailer tires.

Historically, many fleets have gone with just one tire pressure for all their tires, regardless of wheel position; however, this is not recommended. The only advantage of choosing a single tire pressure is that it’s simpler for the shop to only have to recall one number.

Molded onto the tire sidewall of every commercial tire is the maximum -rated load at a specific tire pressure the tire should be inflated to. Choosing this tire pressure is not necessarily what a fleet should be spec’ing. Based on the worst-case load, the recommended tire pressure is found using the load/inflation tables for the specific tire size and load range. It may be 105 PSI for steers, 95 PSI for drives, and 85 PSI for trailers; it all depends.

Looking for more insight on tires ? Click here to read through Al Cohn’s archive of columns.

These load-inflation tables are the same for all tire manufacturers, regardless of tire make/model. They are published on every tire company’s website. For a specific tire size and load range, these tables will list the pressure to carry the load depending if the tire is being run as a “single” or a “dual” configuration.

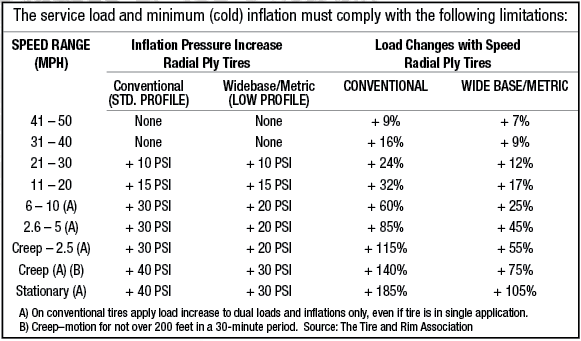

There is a special consideration when it comes to tire pressure recommendations for tires running on “specialized” vehicles at low speeds. The chart above show the tire load increases allowed and the associated increase in tire pressure if a vehicle is always running under 50 MPH. For example, if a vehicle’s top speed was in the 21-30 MPH range, the maximum loaded molded onto the tire sidewall can be increased by 24% with a 10 PSI increase in tire pressure.

It is always a good idea to work with your local tire professional when determining the proper tire inflation pressures for your tires. Checking tires with a calibrated pressure gauge on a regular basis is also strongly recommended. Tires lose 1 to 3 lbs. PSI inflation pressure per month by osmosis through the tire casing. It does not take long for a tire to become significantly underinflated. By definition, a flat tire is a tire that is 20% below specification, and it should be removed from the vehicle and thoroughly inspected to determine why the tire is 20% or more below pressure spec.