How your transmission pairs with your powertrain drastically impacts your truck’s efficiency and productivity. That’s equipment spec’ing 101. So why separate the two when it comes to analyzing your fault code data?

Let’s say that an engine fault code and a transmission fault code happen at the same time. To some, their gut-reaction is that they’re separate service issues, and their mind reels with the potential cost of having to service two major truck components, potentially clouding their service judgment. But what if you knew those two specific fault codes typically occur during a specific powertrain scenario?

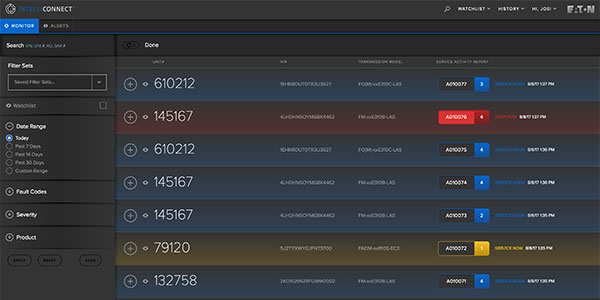

“That’s what Eaton’s IntelliConnect tells you,” said Bobby Robinette, manager of service solutions for Eaton. IntelliConnect is a connected platform that supports remote diagnostics using existing telematics providers, such as Geotab and Omnitracs, which can integrate into Eaton’s portal. “We put together those fault code patterns and try to better analyze the entire system to understand the failure on the vehicle rather than having blinders on and only looking at one specific component.”

Having specific, proprietary knowledge of the transmission’s inner workings provides a high-resolution picture of the service event and gives you a better idea of how to confirm the remote diagnosis once the truck hits the shop.

“We know how to interpret the fault codes from the engine that affect the transmission, which is something other providers can’t do,” said Robert Green, Eaton’s manager of digital engineering. “The telematics system alone would tell you that a specific fault happened, but the fleet’s questions are: ‘What does this mean? Is it an important fault? What should I do?’ We don’t answer every question for every engine fault code, but the ones where we know that a code from the engine affects the transmission, or that code along with a transmission code means something important, we will communicate that to the fleet.”

It’s another piece of the puzzle that can clarify a murky service event. The ability is driven by the increasingly connected component trend.

“Almost every engine is electronically controlled, and it has been that way for a while; electronically controlled transmissions such as AMTs are still relatively new, but they’re growing in popularity. Telematics companies aren’t aware of those equipment trends,” Green explained. “So we walk them through the effects that the transmission’s electronic control system can have on fault codes.”

That equipment insight is turned into actionable guidance for you. As a fleet manager fighting the constant battle to improve uptime and squeeze the most efficiency out of your trucks, this can give you more confidence as to when the vehicle needs service scheduled versus if it needs to stop right away or inform your preventative maintenance plans, depending on fault severity. If a truck does roll into a service center, Eaton’s IntelliConnect platform provides the first steps of diagnosis, troubleshooting guides and an historic rundown of the transmission’s fault codes to speed up a technician’s workflow.

While Eaton IntelliConnect can offer a deeper look at your trucks’ fault codes and the meaning behind them, you have to take the first step. Click here to connect with Eaton and learn more about what IntelliConnect can tell you about your transmissions. Given the service ROI, you’ll be happy you started listening.