Avoiding downtime is crucial to fleet productivity. Unexpected downtime can be related to recurring or unresolved maintenance issues or a surprise CSA citation. Either way, these issues can resolved by increased preventative maintenance or using predictive maintenance to determine when a problem is likely to occur. More and more fleets are making use of technology to help avoid these undesirable and costly delays.

“There are multiple people and multiple systems at every organization that are required in order to process a service event efficiently,” says Michael Riemer, Decisiv’s vice president of product and channel marketing. “Today, that’s all done by telephone, fax, and lots of running around. On average in the trucking industry today, downtime for a breakdown of a truck is about four days—and of those four days, only about four hours are spent on the actual maintenance.

“What’s needed to make this more efficient is access to people and access to information—the remote diagnostics, the service history, etc.,” he continues. “When you do this properly you reduce triage time by 95%, you reduce downtime by 50% and you get a better overall experience because estimates are electronically approved, and you don’t end up with an argument or a surprise by the end. Access to real-time information allows you to make better decisions with better visibility.”

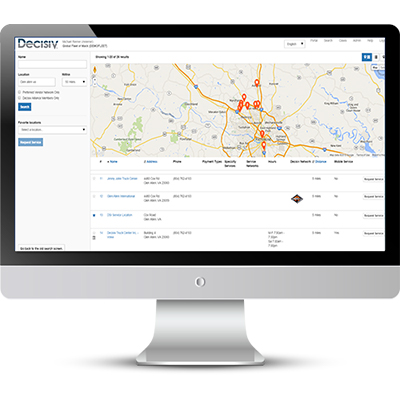

Those percentages come from a case study Decisiv arranged with Oakley Transport. According to the case study published by Decisiv, Oakley found cost savings of $150,000 per year with the use of Decisiv’s Service Relationship Management (SRM) software platform, which was developed with the goal of streamlining all of a fleet’s necessary data into one source to the improve decision-making process and the fleet’s bottom line.

Those percentages come from a case study Decisiv arranged with Oakley Transport. According to the case study published by Decisiv, Oakley found cost savings of $150,000 per year with the use of Decisiv’s Service Relationship Management (SRM) software platform, which was developed with the goal of streamlining all of a fleet’s necessary data into one source to the improve decision-making process and the fleet’s bottom line.

Riemer explains that Oakley Transport found Decisiv SRM platform’s easy access to current event status, asset service history, preventive maintenance schedules, inspection reports, pending operations and more at the point of service allowed the fleet to reduce downtime and eliminate unnecessary service events, resulting in a net improvement of asset utilization rates by 10%.

Other ways the SRM helps fleets with the maintenance process, according to Riemer, include automatically associating a failure or maintenance issue, for example a brake light going out, with the truck in question, “so that the repairs can be done quickly and be visible anywhere the truck goes, whether it’s internal or external,” Riemer says.

“Obviously if you’re doing a good job of keeping up your preventative maintenance, that’s going to go a long way towards keeping your CSA scores low,” he adds. “So we have lots of different ways of helping fleets manage preventative maintenance and report on failures. Let’s say you have a high currency—approximately 90%. That doesn’t necessarily tell you what the quality of those inspections are. We supply some reporting around breakdowns between PMs so that you can see what failures are occurring more regularly and update your inspections to make sure that you’re checking those items more regularly.”