Every single internal combustion engine has torsional vibration.

What is torsional vibration? Torsional vibration is the end to end twisting and rebounding of the rotating assembly caused by internal combustion of an engine during the firing sequence (power stroke). Like the crankshaft, torsional vibrations are found in camshafts as well as drivelines. This event is evident in every engine upon start up and continues while the engine is running. Torsional Vibration becomes harsher as the engine is under load and as power levels increase. Uncontrolled torsional vibration can lead to excessive NVH, premature wear and catastrophic failure.

Who is Vibratech TVD and what is a viscous damper?

Established in 1946, formally known as Houdaille hydraulics, Vibratech TVD is a leader in viscous torsional damper design and development for engines that power our global economy. Vibratech invented the viscous damper in Western New York and still continues to engineer and manufacture our dampers in Springville New York. That’s right, our dampers are machined by us using U.S. steel and iron.

Torsional dampers, every engine has one.

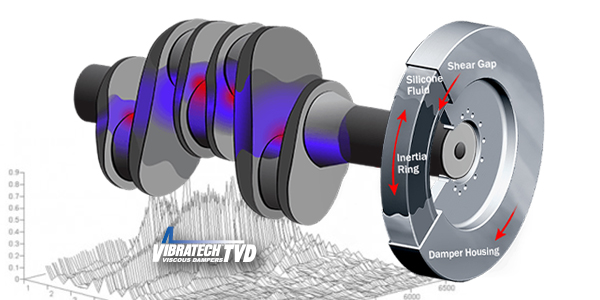

The big round weight on the front of your engine is not just a weight, it is actually an engineered very important functioning part of your engine. Without a damper or with a worn out damper your engine will wear due to uncontrolled vibrations. What makes our dampers unique is our technology used to convert torsional vibrations into thermal energy (heat) protecting and prolonging the life of your engine. Vibratech TVD dampers use silicone as a damping medium inside a steel housing to give a non-bonded internal inertia ring a soft spring rate that while in motion provides a movement known as shear. This technology makes for premium damping.

A genuine Vibratech TVD damper works on a broad range of frequencies produced by the harmonics of the engine. As the damper absorbs these vibrations throughout the entire RPM range the damper turns harmonics in to heat and dissipates it out from the housing material.

Let’s talk about applications.

Vibratech TVD covers a wide range of engine applications including on and off highway trucks, agricultural equipment, power generation, rail, and our high performance Fluidampr aftermarket line. One of our most popular applications is the ISX Cummins*. Let’s compare our Cummins* ISX/ X15 damper (pn:718041-600) to our more recently released Severe Duty damper for the ISX/ X15 engine (pn:1461704-000).

For OTR general purpose use the standard damper works exceptionally well as it has for years. These dampers replaced at the proper intervals will protect the engine from harmful vibrations and premature wear. When engines are being pushed to their limits day in and day out, the severe duty damper picks up where a standard damper will begin to wear. The Vibratech TVD damper is intended for engines that are experiencing front gear case noise, higher horsepower (above 600), as well as engines tasked with pulling multiple trailers including logging and mining operations. The engines that see this extra weight and demand benefit from the extra mass and inertia that the severe duty damper provides. Keeping it at the same OD was critical but we were able to add some depth to the damper adding an overall 37% more mass. Damper durability is also improved for continuous operation in high ambient temperatures.

Vibratech TVD dampers are proudly made in the USA with 100% U.S. sourced materials. Visit www.vibratechtvd.com to learn more and see our many applications.

###

*Vibratech TVD has no connection or affiliation in any way with Cummins Inc. Reference to any trademarked product(s), name(s) or OEM number is intended solely for reference to the usage for that Vibratech TVD part. No products were manufactured by the previous mentioned companies or their suppliers.