Mitchell 1 has added Vehicle Maintenance Reporting Standards (VMRS) codes to its TruckSeries suite of truck repair software solutions for Class 4 to 8 trucks.

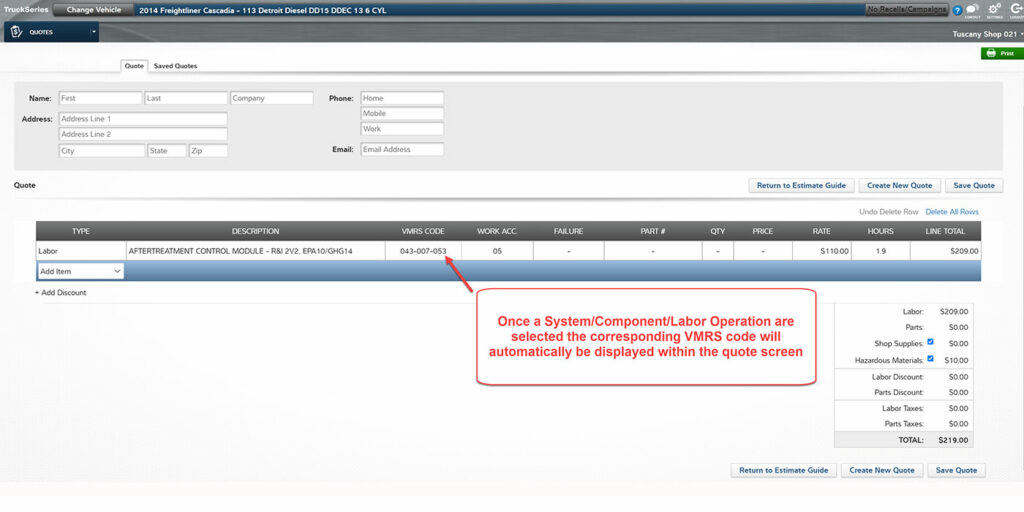

Mitchell 1 says that repair facilities using the Quotes Module in TruckSeries will be able to easily map labor jobs to VMRS codes, giving the vehicle owner a clear and consistent record of repairs and overall costs for each truck in operation. VMRS codes display automatically, eliminating the need to manually look up the appropriate VMRS code for work in progress. TruckSeries presents the appropriate VMRS standardized codes as the quote is generated. Any fleet or shop management system that is VMRS-compliant will recognize the work associated with the code and record the work accordingly, Mitchell 1 says.

“We understand the importance of being able to seamlessly report to fleet operators the detail of the work being done on their vehicles, wherever that vehicle may be,” said Ben Johnson, director of product management for Mitchell 1. “VMRS is an invaluable system but it can be overwhelming to technicians because of the coding complexities that enable the detailed reporting. We’ve stripped out the manual part to make the system easier to use.”

Want to know more about VMRS? Read our recent story here.