Fleets have a number of options when it comes to replacement or upgrades on bearing systems, and with the growing popularity of wide single tires, they should take into consideration their choice of wheel ends due to the offset loads wide singles put on bearings.

Three main choices

The main types of wheel end designs are manually adjusted, pre-adjusted and unitized. The first two are serviceable, but with unitized hubs they are not—if something goes wrong or when it reaches the end of its life, the whole unit is replaced. With the first two, the spindle is the same, but the hub and bearings differ. The pre-adjusted also includes a spacer. Manually adjusted hubs are still the most popular with fleets, although pre-adjusted hubs offer at least two distinct advantages, according to Mark Stangl, fleet sales specialist for bearing manufacturer Timken. “Pre-adjusted wheels offer consistency, neither extreme tightness nor looseness,” he says. The pre-adjusted has a torque spec’, so there is less chance of human error than there is with the procedures a technician must perform when manually adjusting wheel ends. Additionally, pre-adjusted hubs require fewer adjustment steps compared to their manual counterparts. “Less time involved in setting pre-adjusted hubs equals labor-cost savings,” Stangl continues. “Since the pre-adjusted hub is more likely to have correct adjustment, this also will result in longer bearing life,” he notes.

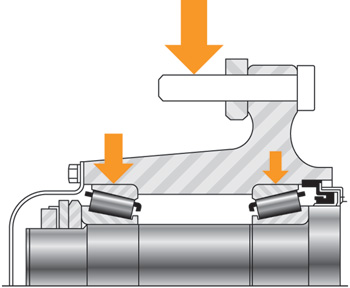

The main differences between the two types are the spacer and specially toleranced hub and bearings that come with pre-adjusted wheel ends.

In pre-adjusted wheel ends, the hub and bearings are machined to tighter than standard tolerances, Stangl explains. This increased precision allows the technician to more quickly and consistently install and adjust the wheel ends. Because the spacer maintains separation of the cones at a precisely engineered distance, the technician is not performing any adjustment with the nut; instead, the tolerances in the hub, bearings and spacer ensure adjustment. The technician only needs to apply the proper clamping force. However, in a manually adjusted wheel end, every rotation of the nut changes the adjustment. The pre-adjusted wheel end removes one variable: the nut merely holds the wheel on––it doesn’t have to provide adjustment as well. That spacer will help technicians put a better product back on the road, says Dan Humphrey, principal application engineer for Timken.

To get a truck back on the road, a pre-adjusted wheel end can be retrofitted as a manual type by removing the spacer.

When to change

When performing service on wheel ends, it may not be necessary to replace the hub and spindle, just the bearings and seals. If damage is found, it’s best to replace all the components to avoid problems later. Rebuild kits such as the Timken Set-Right kit have two bearings and a precision spacer specifically for pre-adjusted wheel ends.

It is important to use the same manufacturer’s cup (outer ring) and cone (inner ring) when replacing a bearing. Although the envelope dimensions may be identical across manufacturers, Humphrey explains, the bearings can differ in internal geometry and material performance. (The company’s Mile Mate sets come with a cup and cone together as a set to help ensure this match.)

Matt Schlagheck, application engineer, NTN Bearing Corp. of America, says that most of the advantages of alternate hub types, such as pre-adjusted or unitized, come in the form of simplified assembly and repair. However, depending on the hub design and the bearings used, there could also be performance advantages.

Schlagheck also recommends that both the inboard and outboard bearings be replaced at the same time, even if there is no apparent damage. “This reduces the likelihood of contamination and other premature failure modes,” he adds.

Leslie Kern, manager of new product development for SKF, notes that fleets need to inspect all components of the wheel end for wear and/or failure. “Performing failure analysis could easily make the difference between getting a refreshed, new life out of the wheel end and another short service interval. The extra time will pay dividends in lowest cost of operation and safety.” If the cone needs replacement, so will its mate (the race). “The cost of repeating a wheel end service is far more than the cost of the race.”

Kern also advises that pre-adjusted hub assemblies have special part numbers. “Do not use standard bearings in a pre-adjusted wheel end unless the spacer is removed and the manual bearing adjustment procedure is followed.” (See TMC RP 618 for details.)

Bearings for wide singles

Wide singles have as much as a two-inch offset that can make a big difference in bearing life. “SKF wheel end bearings have a logarithmic profile that efficiently distributes the load across the rollers while optimizing lubricant distribution,” says Kern.

NTN’s Schlagheck notes the use of a single wide wheel with a hub originally used for dual wheels can alter the load center-line location and subsequent bearing loads. “In this case, it can be even more important to use a good quality bearing from a reliable manufacturer.”

Tracking distance, housing thickness and axle load ratings must all be considered when retrofitting a vehicle to wide-base single wheels, says Bob Crepas, service specialist for Dana Holding Corp. Tracking distance is measured from center-to-center of the tires. Dana publishes guidelines (service bulletin ABIB-0511) that explain the maximum track widths allowable for different axle housing thicknesses versus maximum gross axle weight rating (GAWR). Exceeding these guidelines can cause outer spindle bearing journal wear and/or premature bearing failures, Crepas warns.

Charlie Allen, director-global service, ArvinMeritor, says, “Offset wheels do shift the load line of the hub outward, which places higher load on the outer bearing.” He recommends fleets check with bearing, hub and axle producers for products designed for wide-base single tires.

One example: Timken’s 454-Series bearings are designed with smoother surface finishes and enhanced raceways to provide improved bearing life for the offset loads of wide singles, says Timken’s Humphrey. When used with duals, they also provide increased bearing life, he adds.

Wheel end service

There’s no standard interval for wheel ends servicing, says Humphrey. Typically, brake work or other service sets the timetable. Some fleets go by mileage, while others service them “when things look irregular.” When to expect trouble depends on the vehicle’s use, with refuse trucks needing maintenance more often than line-haul tractors.

ArvinMeritor’s Allen says, “Wheel ends are not ‘set it and forget it.’ They need periodic maintenance.” Follow the OEM’s recommendations for frequency and procedure.

Danny Comer, district manager, Southeast region, Arvin Meritor, adds that end play should be checked at least every 100,000 miles or at least twice a year, especially on the front steer axle. He advises fleets to get a dial indicator so proper wheel bearing end play can be determined.

Dana’s Crepas warns that if the bearings are set too tight or loose, bearing life will drop off dramatically and catastrophic failure could result. Bearings set less than 0.001 in. will induce a preload condition to the bearings. If the bearings are set more than .005 in., excessive wheel endplay will introduce chamber into the wheel that could cause tire wear, difficulty when trying to align the vehicle, decreased bearing life, wheel seal leaks and ultimately, bearing failure.