Gear oils provide multiple important functions when it comes to the operation of gears and axles. As gear oils flow around axles, they help to cool the critical hardware components by carrying heat away and dissipating it. They also help to keep hardware components and assemblies clean by suspending contaminants, which would otherwise lead to carbon, varnish or sludge buildup.

The last, and arguably most important, function of a lubricant is protection. Properly additized gear oils protect hardware from metal-to-metal contact that can cause component damage and complete mechanical breakdown.

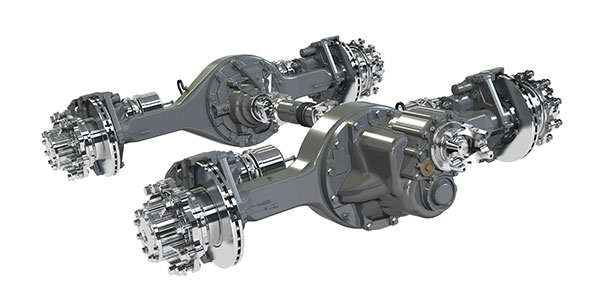

Operational issues such as noise or vibration may indicate improper gear oil and lack of protection. Severe damage can occur when axle components aren’t lubricated by a properly formulated gear oil. Faces of the ring gear teeth can wear badly. Damage on the input pinion can be even more dramatic, with metal loss on the gear. In some situations, gear teeth can break off.

The bottom line for a fleet manager: Without proper gear oil protection, axles can wear out more quickly and need to be repaired or replaced. The result is an increase in dreaded downtime and increased maintenance costs, which lead to lower profits.