How to identify and repair an issue with a spring suspension

Durability is one of trailer spring suspensions’ claims to fame, with spring suspensions often outlasting the life of the trailer. That’s not to say it’s a “spec it and forget it” component. On the contrary, according to Collin Parker, engineering project manager for Hutchens Industries, the number one reason for premature spring suspension failures is

Maintaining bearing maintenance practices

Stemco’s product manager for engineered products, Vincent Purvis, said that in addition to TMC’s RP618A, “Wheel Bearing Adjustment Procedures,” fleets should also consider proper lubrication of wheel end bearings and systems as referenced in TMC’s RP631B. He highlighted the use of Stemco’s Pro-Torq or Zip-Torq nut to ensure proper wheel end play, and recommended the

The importance of keeping your axle vents in good condition

Axle vents are something few people ever think about, but they play an important role in keeping the axle in operating condition. Axles generate a lot of heat running down the road. As the axle increases in temperature, the air pressure inside the axle likewise increases. To accommodate the increase in air pressure resulting from

Common wheel-end service misconceptions

In servicing commercial vehicle wheel-ends, fleets and operators sometimes rely on industry practices that are accepted, trusted—and may no longer be valid. This installment of the Bendix Tech Tips series from Bendix Commercial Vehicle Systems LLC and Bendix Spicer Foundation Brake LLC (BSFB) addresses five common misconceptions, offering the facts behind each to help industry

Preventing fuel gelling in the common rail engine

The efficiency of fuel filters has come a long way over the past decade. In fact, most common rail engines being produced today include a factory fuel filter rated at a 2-5 micron efficiency, while just a few years ago they were being produced with a 10-20 micron rating. Although the tighter tolerances of

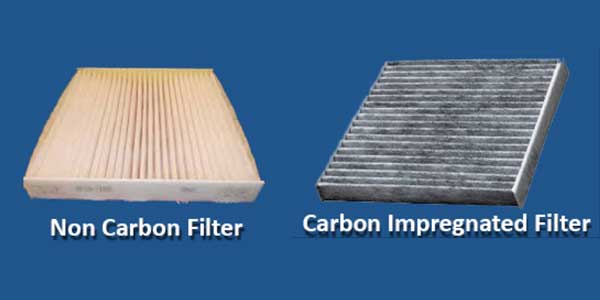

Maintaining good air quality in your truck’s cab

A long-haul truck driver can spend up to 24 hours in his or her cab and/or sleeper. The air quality in that small space is important to the driver’s health. Almost all trucks, today, come with a cabin air filter designed to clean all air entering the truck. The device using a filter media much

Preparing wheel-ends, air dryers for winter

Across North America, it’s getting to be that time of year: Temperatures are dropping, and fleets and owner-operators are prepping for chilly conditions and wintry roads. Before things get too harsh out there, the Bendix Tech Tips series from Bendix Commercial Vehicle Systems LLC and Bendix Spicer Foundation Brake LLC (BSFB) offers some simple steps

Preventative maintenance to ensure stiction removal

Today’s engines rely heavily on proper lubrication to run at maximum efficiency. Even a properly maintained engine can lose up to 4 HP per year. Of course, some of the loss is due to component wear such as worn cylinder rings. Other losses are due to sludge or varnish build up that degrades performance. Sludge

Bendix outlines recommended procedures for flood-damaged air brake systems

In countless ways, this hurricane season’s extensive and severe flooding has been devastating for people and property. With truck drivers and the trucking industry so vital to the recovery and rebuilding efforts in these areas, it’s important to keep tractors and trailers in safe operating condition and help avoid future issues if they’ve been exposed

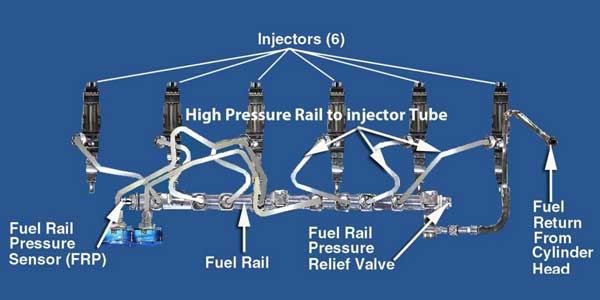

Keeping up with fuel injection technology

Diesel engines are getting close to the theoretical limits of efficiency. To show how far we have come, consider Rudolf Diesel. On Feb. 17, 1897, he demonstrated an efficiency of 26.2% with the engine he made. In contrast, the average steam engine he was competing with was around 10% efficiency. Fuel systems are an area