It’s one thing to see what’s on the road ahead of you, it’s another to know what that object is that’s in front of you. We take it for granted, the box is clearly a box, the blown tire is clearly rubber laying on the road. But as someone who has changed a tire on the side of the Turnpike, we don’t always avoid the debris in the road that can cause an unplanned service issue. Automated trucks, however, need to be perfect. Or as close to perfect as you can get.

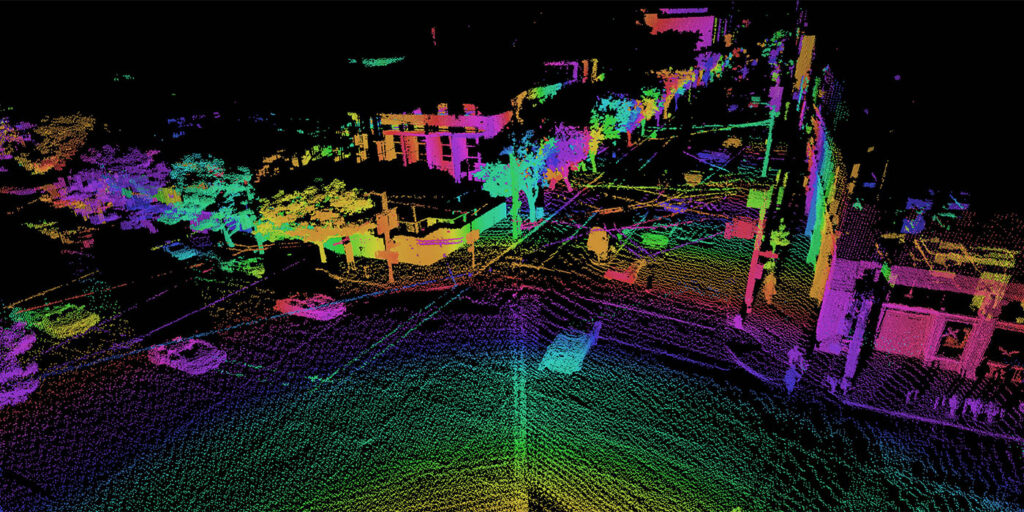

That’s why talk of lidar (light detection and ranging) sensors swirl within the automated driving conversation. The devices send out light that is then collected and turned into three-dimensional images that look like this:

Clearly that one is mounted above street level. On automated trucks, they’re typically mounted on the side of the truck near the roof fairing/sun visor area and potentially lower on the hood depending on the system. One question within trucking application, is durability. Lidar is a precision instrument and the road is anything but smooth.

For an understanding of how lidar is making its way into automated trucking systems and to discuss the need for durability, I connected with Andrew Nelson, vice president of sales, AEye, who laid out the lidar roadmap for automated truck driving. Watch the video above for all of his insight.

Staying in a lane

For what it’s worth, my memory can be shaky but I was within the ballpark when I mentioned the possibility of automated vehicle lanes, ABC News has that story.

No script? No plan? No problem. Welcome to Fleet Equipment Unscripted—the video interview series that connects you with the greatest minds in the heavy-duty trucking world.

Bookmark the Fleet Equipment Unscripted page to catch all of our Unscripted episodes, and subscribe to our newsletter by clicking here to have the latest news and in-depth trucking stories delivered straight to your inbox.

Fleet Equipment Unscripted is sponsored by Hendrickson.