Every truck suspension option comes with its own unique performance trade-offs. The best choice requires an understanding of how the trade-offs match up to your application requirements.

The right suspension can maintain a tractor-trailer’s road handling and ride quality, and helps minimize the amount of jarring (bumps, vibrations) for improved load-carrying ability. This protects both the trailer and the freight inside from being damaged, and also cushions the chassis from road shock, enabling the driver to steer. The right suspension also maintains the proper axle spacing and alignment.

To help you decide what will work best for you, let’s walk through the basics of the two most common suspensions used in trucking: air ride and leaf spring.

Air ride systems

Air ride uses a variety of valves, airlines and air-spring bags in place of steel suspension. The flexible air-spring bags are made from a woven and rubber-like material. The air supplied to the air-ride suspension uses the same air compressor and air reservoir as a truck’s braking system (See Figure 1).

The supplied air pressurizes the air-spring bags, creating a spring-like motion that raises the chassis from the axle. Air suspensions are more complicated but often provide a smoother ride and keep sensitive cargo for getting damaged. Using air ride can also make unhooking trailers much easier by using the dump valve to lower the truck enough to pull away from the trailer. But if air ride is used on a dump application you must release air pressure before lifting the bed due to the fact that the dump bed at full height will sway back and forth and could tip over.

Leaf spring systems

Spring suspensions use semi-elliptic leaf springs to cushion a load from road shock. As one of the most commonly used suspensions, spring ride consists of several layers of flexible steel strips referred to as a “leaf pack.”

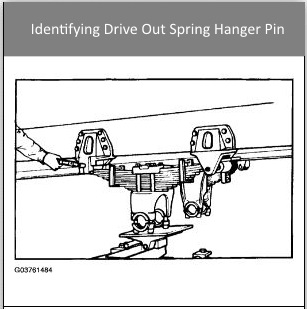

The strips are joined together to act as a single unit. The long and narrow arch-shaped plates are attached to the frame of a trailer, resting above the trailer’s axle. (See Figure 2)

Spring suspensions are sometimes a harsher ride but are often less expensive to repair due to their simple nature. Spring suspensions are generally used for more heavy duty applications where ride isn’t as important and the cargo is not as sensitive (construction, refuse, off road etc.)

With all of the choices on the market, finding the best suspension for your operation can be a daunting task. It’s best to seek expert advice rather than go it alone. Ask for input from a respected sales professional with specific expertise in suspension applications. Make sure they know exactly under what conditions the truck will be operating, and inform them what you are hoping to spend on operational cost. Lastly, try to get feedback from other fleet or maintenance managers who do similar work—ask them what they use and why.

This article was contributed by Kurt Schneider, technical editor for Mitchell 1’s Commercial Vehicle Group. Additional tips for repair and maintenance of Class 4-8 trucks can be found in the Mitchell 1 ShopConnection Truck blog.