Selecting the correct suspension system can go a long way in both fuel efficiency and weight savings. If the correct suspension is paired with the proper powertrain, you can have gain efficiency without putting on the pounds.

SAF-Holland offers the Neway suspensions. On the drive suspension side, the ADZ capacities are 46,000 and 52,000 lbs. per tandem. It is also available in single and tri-drive applications. It is 500 lbs. lighter per tandem compared to its predecessor, the AD suspension. On the auxiliary side, the recently-released LSZ, the first in a new line of auxiliary steerable lift axles, is equipped with its lighter-weight wheel end package weighing in at just 936 lbs.“When you complement the weight savings of the ADZ and the LSZ’s small packaging envelope you maximize the efficiency of your truck,” said SAF-Holland’s Heath. “The amount of payload you can carry in your truck is maximized, which means you can haul more in fewer trips.”

The buzz around 6×2 axles is growing (check out the Heavy-duty News column) because the fuel economy savings with a 6×2 system is realized through eliminating the parasitic losses and resistance of the additional gears typically required to drive the second drive axle in a 6×4 application, explained Sean Whitfield, commercial and marketing manager for Hendrickson Truck Commercial Vehicle Systems.

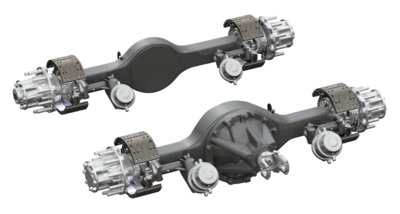

In terms of weight savings, today’s 6×2 systems—offered by the likes of Meritor, Hendrickson, Dana and Detroit—can save anywhere from 300 to 400 lbs. Typical 6×2 systems can increase fuel economy by 2 ½ to 3% just by eliminating the second drive axle and replacing it with a non-driven axle.

Meritor offers its FUELite SoloDrive Series axles that feature 6×2 tandem rear axles, with a 2.50 to 4.10 ratio range. The FUELite axle aims to accommodate all 40,000-lb. linehaul suspensions. It offers a weight savings of 370 to 400 lbs. and, when coupled with wide-base tires, can offer an additional 400 lbs. of weight savings. Meritor customer field-testing has shown a 2.5% efficiency improvement over a 6×4, the company reported.

Hendrickson OPTIMAAX delivers a weight savings between 300 to 350 lbs. over the conventional 6×4 configuration and an additional 2% (on top of the typical 2.5 to 3%) by eliminating the rolling resistance of the forward tandem axle by lifting the axle when the additional load carrying capacity is not required. “OPTIMAAX liftable forward tandem 6×2 system is unique in that when the GVWR is lighter than 63,000 lbs., the non-driven axle is lifted, which eliminates the rolling resistance of the forward tandem axle while maintaining optimum traction and mobility thus optimizing the tractor trailer combination during fluctuating load capacities,” Whitfield explained.

Hendrickson also offers the PRIMAAX EX vocational air suspension, which is available in 46,000- and 52,000-lb. capacities for tandem and scalable downward for single axles or upward for tridem axle configurations.

Dana’s Spicer EconoTrek 6×2 tandem axle for 40,000-lb. linehaul tractors reduces weight by up to 400 lbs. compared to a 40,000-lb. tandem drive axle. Producing fuel savings from 2 to 3% as a result of these significant weight savings, as well as decreases in mechanical drivetrain energy loss, this translates into reduced fuel costs of over $1,400 a year for a Class 8 truck logging 120,000 miles at 6.5 miles per gallon. The EconoTrek combines Spicer S170 and S190 single-reduction drive axles with a Spicer S20-045B tag axle.

“A 6×2 configuration is ideal for fleets that operate in consistently good weather and traction conditions, while a 6×4 configuration is better suited for heavy grades, frequent inclement weather conditions and other situations where traction is commonly a problem,” explained Santiago Salazar, senior director of global product planning for Dana Commercial Vehicle Driveline Technologies. “Before specifying a 6×2 configuration, fleet operators should consider the duty-cycle consistency of their fleet. If a fleet is mixing vocations and duty cycles, they may want to consider a 6×4 configuration for the versatility it offers.”