The continued integration of powertrain components propels advancements in downspeeding as ratio speeds increase. In fact, Dana recently announced a new 2.47:1 axle ratio for the Spicer AdvanTek 40 tandem axle. Meritor’s new 14X HE tandem axle has ratios down to 2.15. According to Ken Hogan, Meritor’s vice president of rear drivetrain, approximately 25% of today’s trucks have ratios faster than 2.64. There is no slowing down for downspeeding.

To achieve increase efficiency, downspeeding demands that the entire system must be matched, including engine, clutch, transmission, driveline, axle model and ratio, along with tires. Each of these working together is needed to optimize fuel economy, startability and gradeability. Additionally, higher torques created by downspeeding place higher stress on the drivetrain components, which means that you need sturdier driveline components to stand up to downsped demands. In a 2014 whitepaper entitled “The Right Solution for Downsped Engines,” Dana cited that by decreasing an engine’s RPM at cruise speed from 1,450 RPM for the typical engine to 1,125 RPM for a downsped engine, torque loads in the driveline increase by 57%.

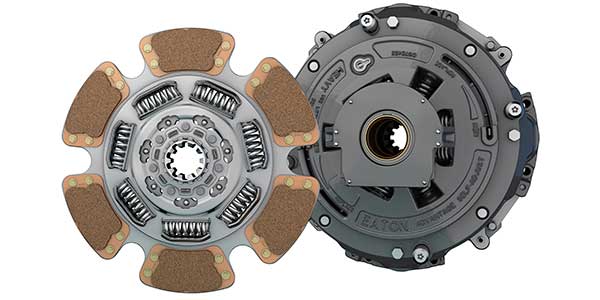

In addition to torque stress, downspeeding also impacts the engine’s torsional vibrations, which can be harmful to the transmission and other drivetrain components. The clutch can play a key role in protecting your drivetrain from harmful vibrations. To combat this issue, Eaton recently announced upgrades to its line of Advantage Series heavy-duty clutches, which include new soft rate dampers to absorb vibrations with the goal of preserving driveline components.

“One of the things that a clutch does is that it dampens engine torsional vibration and protects the transmission and driveline from those torsionals,” said Ben Karrer, global product strategy manager for Eaton. “Downspeeding causes the truck to see more vibration—it aligns that natural frequency of the driveline to the frequency of the engine, and the clutch dampens those vibrations by allowing more travel and a softer rate in the clutch damper. So we’ve made our softest rate damper standard across our clutch portfolio.”

This damper technology enables downspeeding at all torque ratings up to 1,850 lb./ft., according to Eaton.

Another protective feature is that the intermediate plate is now connected to the rest of the clutch by a strap-drive. “This does two things for you: First, it improves the durability pretty dramatically,” Karrer said. “The lugs were an occasional source of fatigue failure, and that was compounded by some of the trends that are leading to more clutch open time, such as inexperienced drivers.

“The second benefit is that it eliminates some rattle noises that you hear in a clutch when the clutch is disengaged,” Karrer said. “The improvements we have made support the changing requirements of contemporary diesel engines and powertrains, including downspeeding designs.”

Eaton has clutches in this portfolio that range from 1650 ft./lbs. to 2250 ft./lbs., and they will be available later this year.