The Commercial Vehicle Safety Alliance (CVSA) is an organization that establishes out-of-service standards for commercial vehicles operating in North America. CVSA level I and Level V inspections can place a vehicle out of service if violations are discovered during the inspection process.

Level 1 inspections review driver qualifications/standards as well as critical vehicle areas that include the vehicle brake system, coupling systems, exhaust systems, frame, fuel system, lighting system, vehicle loading, steering system, suspension system, tires, wheels and rims, wipers and emergency exits on busses.

Level V is a vehicle-only inspection that includes the systems outlined in the above Level I inspection, but the driver is not present and this inspection can be performed at any location.

A vigorous preventive maintenance (PM) program that includes a thorough operator pre-trip inspection can identify issues that can be corrected before they turn into a vehicle out-of-service violation causing excessive vehicle downtime. The Mitchell 1 TruckSeries product provides valuable service information and specifications that can be used by service personnel to prevent the vehicle from being placed out of service by CVSA inspectors.

Information in TruckSeries that will prevent Out of Service violations include:

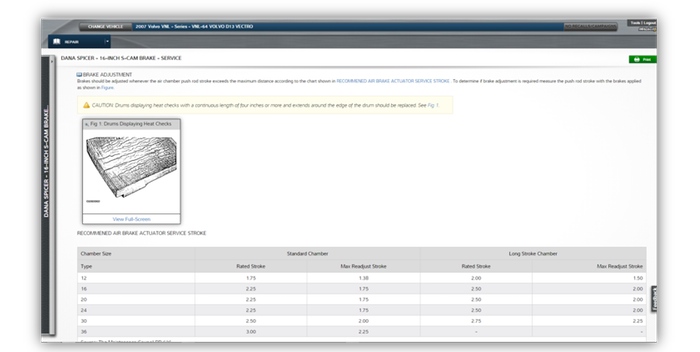

1. Brake Drum inspection and Brake Chamber stroke specifications

2. Brake Pad and Rotor Wear Limits:

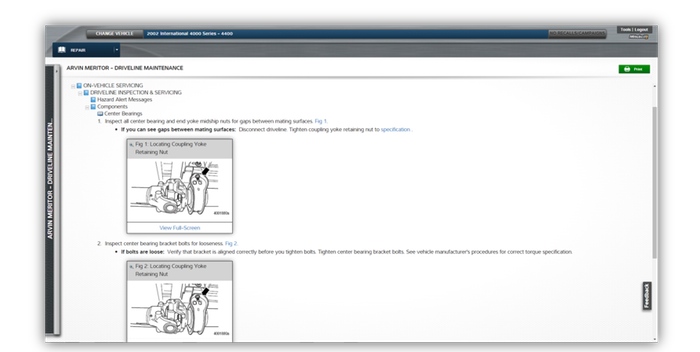

3. Driveline Center Bearing Servicing:

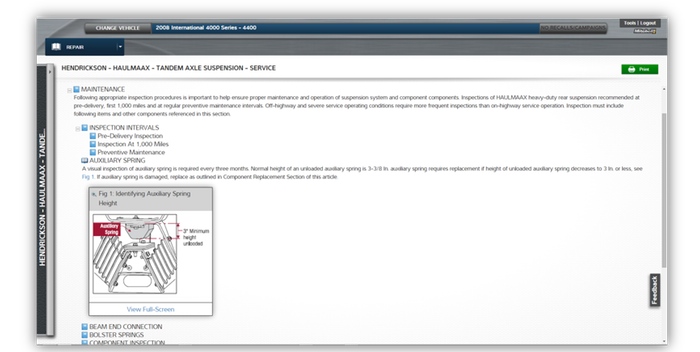

4. Rear Suspension Service information

One especially critical vehicle inspection area is the braking system. If 20% of the total brakes on the vehicle are determined to be defective based on criteria established in “North American Standard Out-of-Service Criteria handbook,” the vehicle will be placed out of service, and an Out of Service sticker applied to the vehicle by CVSA inspectors.

The 20% rule applies to all the brakes on the vehicle, or vehicle combination. To illustrate, let’s apply the 20% rule formula to a typical 18 wheeler (tractor trailer combination) that has 18 brake assemblies on its wheel ends. If four brakes are determined to be defective, the vehicle will be tagged as being out of standards and will require that violations be repaired and the vehicle re-inspected before being placed back into service.

Some issues that will place a brake out of standards that are included in the 20% rule include:

1. Any axle that is required to have brakes installed and the brakes are missing

2. No effective braking action when the brakes are applied

3. An air leak due to ruptured brake diagrams, loose chamber clamps, bad air lines or leaking brake valves

4. Brakes out of adjustment

5. Broken brake parts

6. Disk brake pad worn less than 1/16 in. (1.6 mm) or into wear indicator

7. Cracks in linings longer than 1 ½ in. or wider than 1/16 in.

Refer to the current version of the North American Standard Out-of-Service Criteria Handbook for a complete list of critical inspections and their related out of service criteria and FMCSA regulations. For more tips like these, be sure to visit Mitchell 1’s blog.